Preparation method and application of normal hydrocarbon hydroisomerization catalyst

A hydroisomerization and catalyst technology, which is applied in the field of preparation of new normal hydrocarbon hydroisomerization catalysts, can solve the problems of cost increase, reduction of catalyst acidity, pore structure damage, etc., and achieve good heat and water Effects of thermal stability, increase in specific surface area, and increase in utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a treated substrate, which is prepared by the following steps:

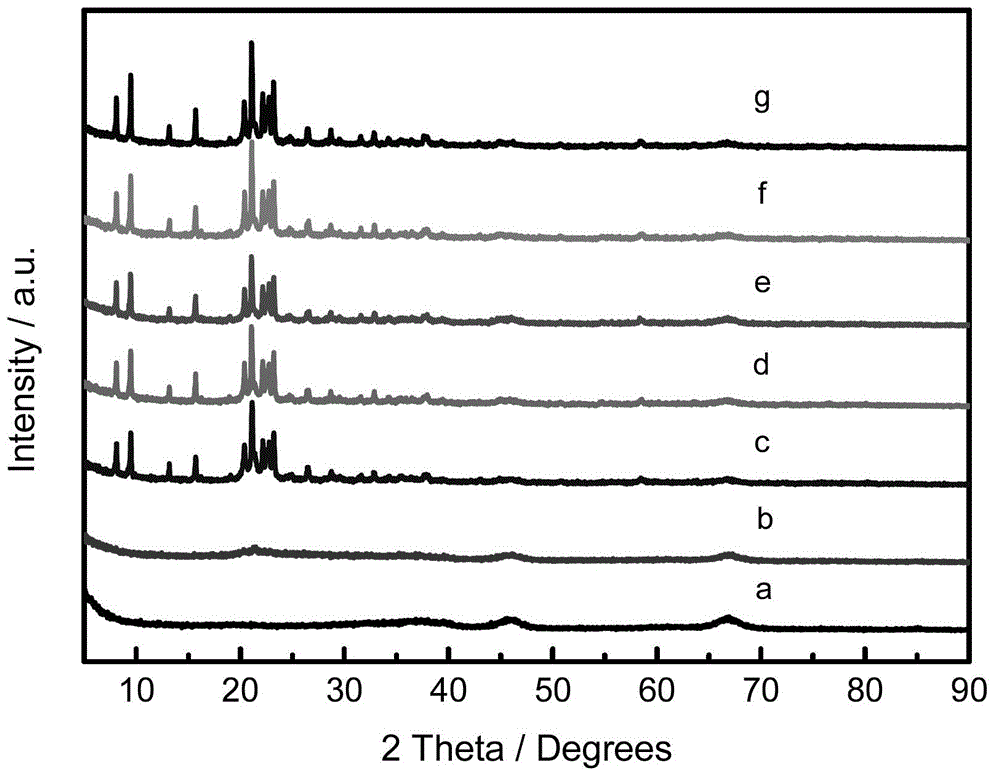

[0035] Mix 40g of pseudo-boehmite, 1g of turnip powder, 10g of concentrated nitric acid and 20g of deionized water evenly, and then extrude into strips with a diameter of 1.5mm. Dry it in the oven for 6 hours, take it out and cool it, then bake it at 520°C for 4 hours, the heating rate is 2°C / min, the powder XRD spectrum is as follows: figure 1 as shown in a;

[0036] Put the roasted product in a phosphoric acid solution with a concentration of 2.5mol / L, and treat it at 70°C for 12h; Dry 6h in oven, obtain the matrix after final treatment, its powder XRD pattern is as follows figure 1 As shown in b, the pore structure parameters are shown in Table 1.

Embodiment 2

[0043] This embodiment provides a catalyst for hydroisomerization of normal hydrocarbons, which is prepared according to the following steps:

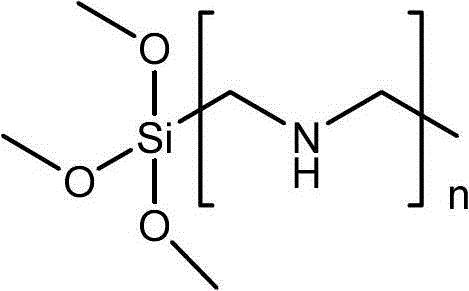

[0044] After mixing 55g of deionized water and 6.5g of phosphoric acid (85wt.%), add 2.7g of pseudoboehmite, 1.3g of tetraethyl orthosilicate and 5.3g of di-n-propylamine in sequence, stir for 2 hours each, mix well, and then Add 0.5g of diethylenetriaminopropyltrimethoxysilane (95wt.%) solution (dissolved in 5.0g deionized water, stir for 12h), continue to stir for 12-14h to obtain a sol, add the treatment prepared in Example 1 The final matrix was 12.5g, and finally at 185°C, dynamic hydrothermal crystallization was carried out for 48h;

[0045] The dynamic hydrothermal crystallization product was washed with deionized water to pH = 7, separated, placed at room temperature for 12 hours to dry, then placed in an oven at 120°C for 12 hours, and finally calcined at 600°C for 6 hours to obtain a stepped pore SAPO -11 / γ-Al 2 o 3 Compos...

Embodiment 3

[0048] This example provides a catalyst for hydroisomerization of normal hydrocarbons, the preparation steps of which are similar to Example 2, except that 2.7g of pseudo-boehmite is replaced with 8.6g of aluminum isopropoxide, and other conditions are not changed. Change, get step hole SAPO-11 / γ-Al 2 o 3 Composite material, its powder XRD pattern is as follows figure 1 As shown in e, the pore structure parameters are shown in Table 1;

[0049] With the above step hole SAPO-11 / γ-Al 2 o 3 The composite material is used as a carrier, and the equal volume impregnation method is used to impregnate 0.5wt.% of Pt and 0.5wt.% of Pd (based on the total mass of the catalyst finally obtained), then dry at room temperature, dry at 120°C for 3h, and 500 Calcined at ℃ for 4h to obtain normal hydrocarbon hydroisomerization catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com