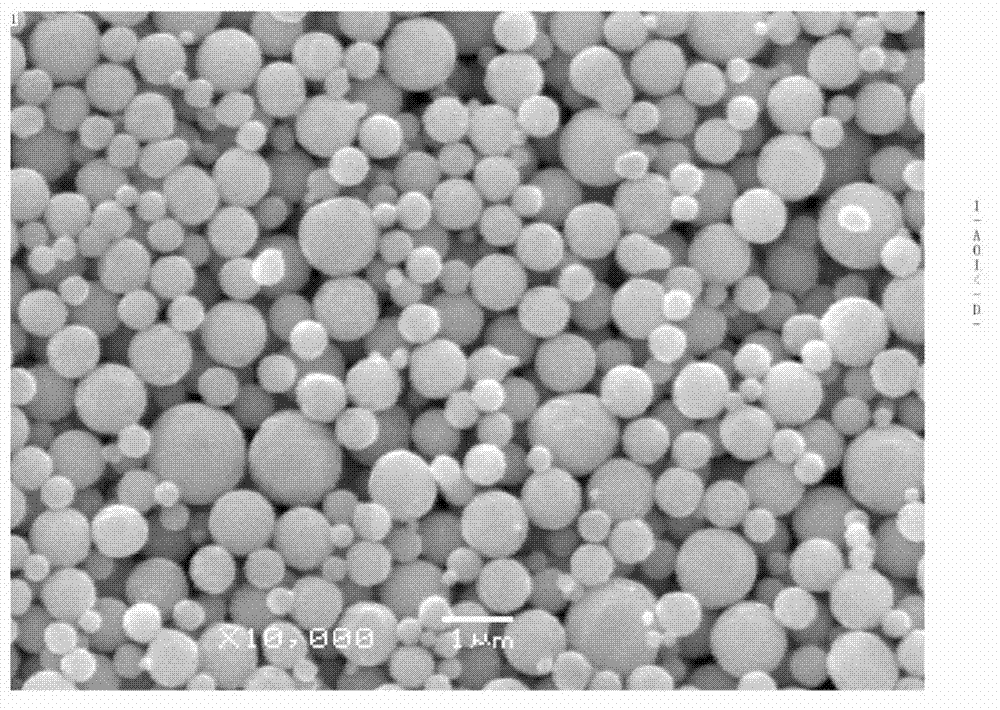

Production method of submicron-order tin-copper alloy powder

A technology of tin-copper alloy and production method, which is applied in the field of production of sub-micron tin-copper alloy powder, can solve the problems of large particles, uneven surface and high sintering temperature of tin-copper alloy powder, and achieves uniform particle size distribution and powder flow. Good performance and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The production method of tin-copper alloy powder in this embodiment is carried out in a reaction system consisting of a high-temperature evaporator with a plasma generator, a particle controller, and an alloy powder collector, which are sequentially connected at the top, and specifically includes the following steps:

[0024] (1) First, the tin raw materials and copper raw materials are fed into the crucible in the high-temperature metal evaporator through the feeding port at the flow rate of 0.8kg / h and 2.4kg / h. After the air tightness of the equipment is qualified, the reaction system is vacuumed. Then flush the reaction system through a valve at the bottom of the high-temperature evaporator and fill it with nitrogen, keeping the internal atmosphere of the system inert and the pressure at 110kPa;

[0025] (2) Turn on the plasma generator set on the top of the high-temperature evaporator to generate high-frequency plasma gas as the heating source, heat the tin and copper raw...

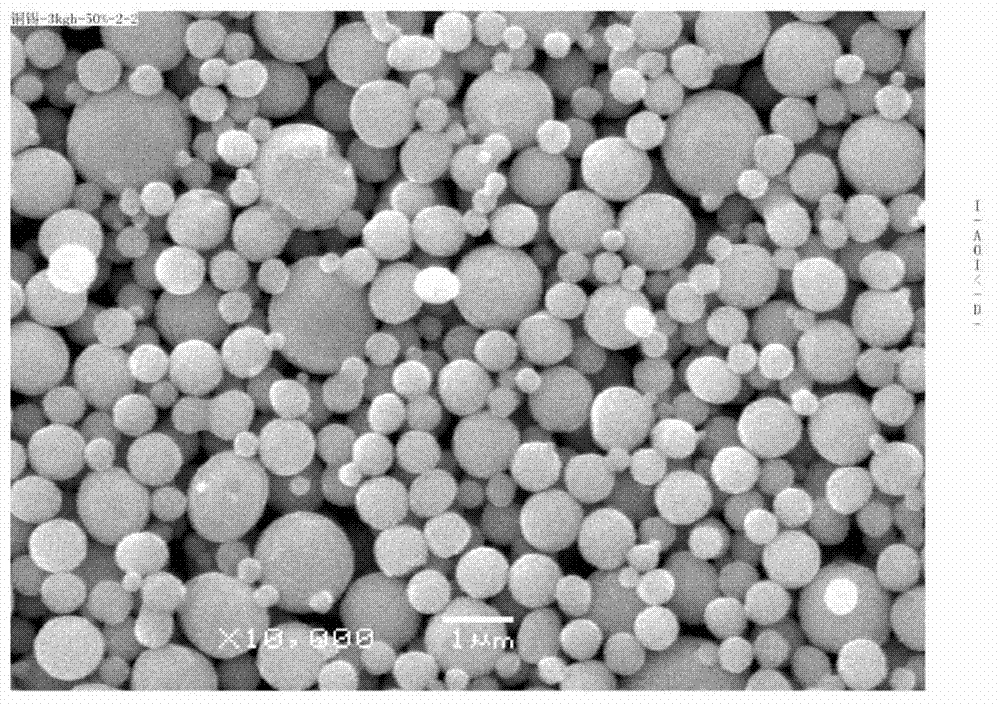

Embodiment 2

[0032] The production method of tin-copper alloy powder in this embodiment is carried out in a reaction system of a high-temperature evaporator, a particle controller, and an alloy powder collector connected in sequence, and specifically includes the following steps:

[0033] (1) First, the tin raw materials and copper raw materials are fed into the crucible in the high-temperature metal evaporator through the feeding port at a flow rate of 1.5kg / h and 1.5kg / h. After the air tightness of the equipment is qualified, the reaction system is vacuumed. Then flush the reaction system through a valve at the bottom of the high-temperature evaporator and fill it with nitrogen, keeping the internal atmosphere of the system inert and the pressure at 110kPa;

[0034] (2) Turn on the plasma generator set on the top of the high-temperature evaporator to generate high-frequency plasma gas as the heating source, heat the tin and copper raw materials to a molten state, and continue to raise the temp...

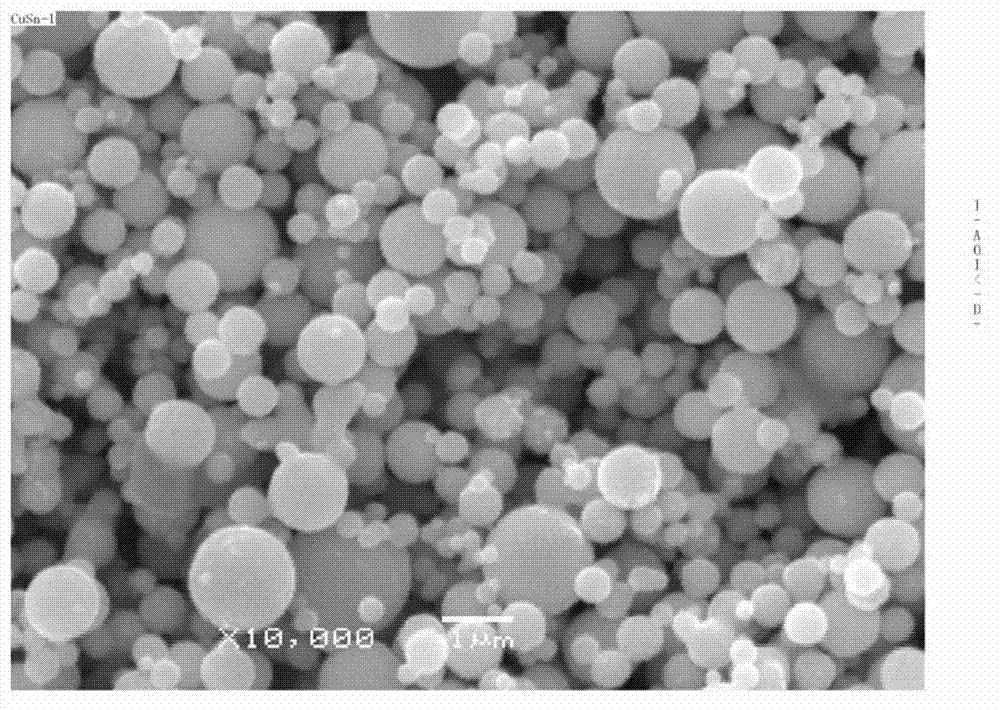

Embodiment 3

[0041] The production method of tin-copper alloy powder in this embodiment is carried out in a reaction system consisting of a high-temperature evaporator with a plasma generator, a particle controller, and an alloy powder collector, which are sequentially connected at the top, and specifically includes the following steps:

[0042] (1) First, add the tin and copper raw materials into the crucible in the high-temperature metal evaporator through the feeding port at the flow rate of 0.8kg / h and 2.4kg / h. After the air tightness of the equipment is qualified, the reaction system is vacuumed. Then flush the reaction system through a valve at the bottom of the high-temperature evaporator and fill it with nitrogen, keeping the internal atmosphere of the system inert and the pressure at 110kPa;

[0043] (2) Turn on the plasma generator set on the top of the high-temperature evaporator to generate high-frequency plasma gas as the heating source, heat the tin and copper raw materials to a mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com