Environment-friendly preparation method of multi-hydroxyl polymer molecular brush

A polyhydroxy polymer, an environmentally friendly technology, applied in the field of polymer chemistry, can solve the problems of toxic halides, high cost and toxic catalyst ligands, and achieve the effects of no toxicity, strong protein adsorption resistance, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

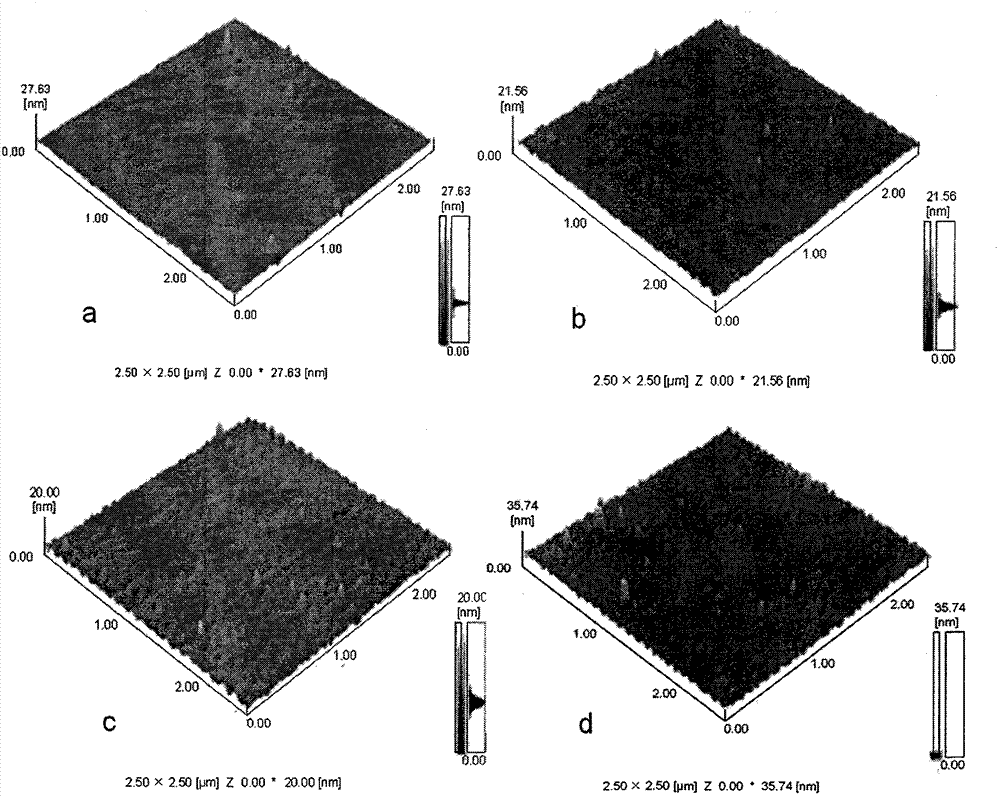

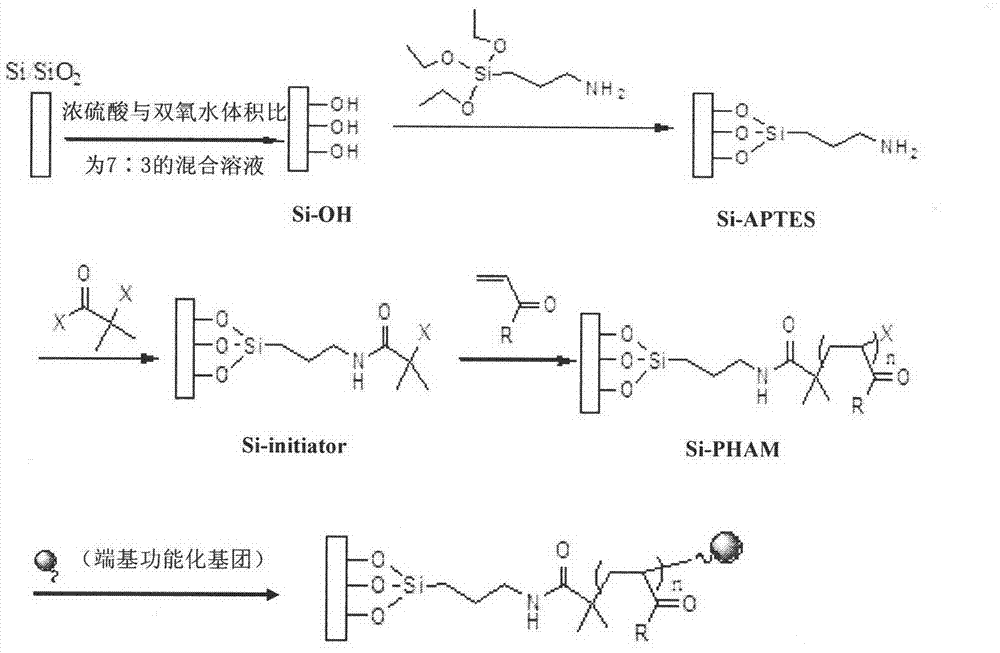

[0031] 1) Surface treatment of the substrate: place the silicon substrate in a mixed solution with a volume ratio of concentrated sulfuric acid and hydrogen peroxide of 7:3, and after treatment at about 90° C. for 90 minutes, place the silicon substrate in acetone and water for sonication for 10 minutes. Rinse with water, and finally blow dry the surface of the substrate with nitrogen to obtain a hydroxylated silicon substrate Si-OH, such as figure 1 shown.

[0032] 2) Assembly of the aminosilane coupling agent: The newly prepared surface hydroxylated substrate was placed in 30 ml of a toluene solution containing 2.1 mmol of 3-aminopropyltriethoxysilane, heated to 80°C, and reacted for 24 hours. Take out the substrate, rinse the substrate with toluene, methanol, water, and acetone three times in turn, and blow dry the surface of the substrate with nitrogen to obtain a silane-modified silicon substrate Si-APTES, such as figure 1 shown.

[0033] 3) Modification of initiator: t...

Embodiment 2

[0037] 1) Surface treatment of the substrate: place the silicon substrate in a mixed solution with a volume ratio of concentrated sulfuric acid and hydrogen peroxide of 7:3, and after treatment at about 90° C. for 90 minutes, place the silicon substrate in acetone and water for sonication for 10 minutes. Rinse with water, and finally blow dry the surface of the substrate with nitrogen to obtain a hydroxylated silicon substrate Si-OH, such as figure 1 shown.

[0038] 2) Assembly of the aminosilane coupling agent: The newly prepared surface hydroxylated substrate was placed in 30 ml of a toluene solution containing 2.1 mmol of 3-aminopropyltriethoxysilane, heated to 80°C, and reacted for 24 hours. Take out the substrate, rinse the substrate with toluene, methanol, water, and acetone three times in turn, and blow dry the surface of the substrate with nitrogen to obtain a silane-modified silicon substrate Si-APTES, such as figure 1 shown.

[0039] 3) Modification of initiator: t...

Embodiment 3

[0043] 1) Surface treatment of the substrate: place the silicon substrate in a mixed solution with a volume ratio of concentrated sulfuric acid and hydrogen peroxide of 7:3, and after treatment at about 90° C. for 90 minutes, place the silicon substrate in acetone and water for sonication for 10 minutes. Rinse with water, and finally blow dry the surface of the substrate with nitrogen to obtain a hydroxylated silicon substrate Si-OH, such as figure 1 shown.

[0044] 2) Assembly of the aminosilane coupling agent: The newly prepared surface hydroxylated substrate was placed in 30 ml of a toluene solution containing 2.1 mmol of 3-aminopropyltriethoxysilane, heated to 80°C, and reacted for 24 hours. Take out the substrate, rinse the substrate with toluene, methanol, water, and acetone three times in turn, and blow dry the surface of the substrate with nitrogen to obtain a silane-modified silicon substrate Si-APTES, such as figure 1 shown.

[0045] 3) Modification of initiator: t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com