Battery separator film and preparation method thereof

A technology of battery diaphragm and diaphragm material, applied in battery pack parts, circuits, electrical components, etc., can solve the problem of low closed cell temperature, poor puncture tensile strength, air permeability of battery diaphragm, and unsatisfactory film breaking temperature at high temperature, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

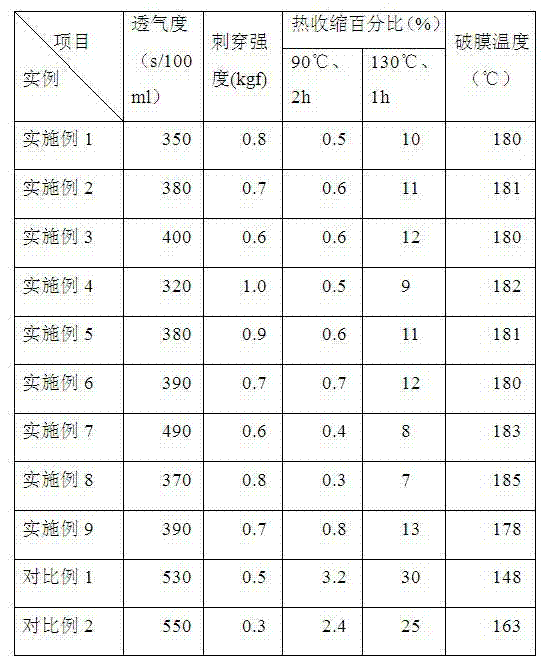

Examples

preparation example Construction

[0021] The present invention also provides a method for preparing a battery diaphragm, comprising the following steps:

[0022] (a) dissolving and plasticizing the polyethylene mixture and the first solvent to obtain a polyethylene melt; dissolving and plasticizing the polymethylpentene and the second solvent to obtain a polymethylpentene melt;

[0023] (b) mixing polyethylene melt and polymethylpentene melt, casting, cooling, stretching, extracting, drying, and heat setting to obtain a separator;

[0024] Wherein, the first solvent is a good solvent for polyethylene, preferably, one or more selected from decahydronaphthalene, kerosene, liquid paraffin or paraffin; the second solvent is a good solvent for polymethylpentene, preferably , selected from one or more of liquid paraffin, paraffin, benzene, toluene, methanol, cyclohexane, trichloroethylene, tetrahydrofuran, pyridine or butanone.

[0025] In the preparation method of the battery separator provided by the present inve...

Embodiment 1

[0050] The diaphragm in this example is made through the following steps:

[0051] (s1) 5kg, weight average molecular weight of 1.5×10 6 , ultra-high molecular weight polyethylene with a molecular weight distribution of 6, 17.5kg, and a weight-average molecular weight of 2.5×10 5 , high-density polyethylene with a molecular weight distribution of 10.8, 2.5kg, and a weight-average molecular weight of 1×10 4 , low-density polyethylene with a molecular weight distribution of 12, 0.1 kg of 3-(3,5-di-tert-butyl-4-hydroxy)propenyl octadecyl ester and 0.025 kg of tris[2,4-di-tert-butylphenyl] Phosphite and 50kg of liquid paraffin are continuously fed into a twin-screw extruder with a length-to-diameter ratio of 40, and melted and plasticized at a temperature of 160°C-240°C and a shear rate of 120r / min to obtain a molten polyethylene mixture. body;

[0052] 10kg, the weight average molecular weight is 5×10 5 , melt index is 23dg / min, poly-4-methyl-1-pentene and 15kg liquid paraffi...

Embodiment 2

[0060] The difference from Example 1 is that: in step (s1), 1.25kg, weight average molecular weight of 1.5×10 6 , ultra-high molecular weight polyethylene with a molecular weight distribution of 6; 18.75kg, a weight-average molecular weight of 2.5×10 5 , high-density polyethylene with a molecular weight distribution of 10.8; 5kg, a weight-average molecular weight of 1×10 4 , low-density polyethylene with a molecular weight distribution of 12, 0.1 kg of 3-(3,5-di-tert-butyl-4-hydroxy)propenyl octadecyl ester and 0.025 kg of tris[2,4-di-tert-butylphenyl] Phosphite and 50kg of liquid paraffin are continuously fed into a twin-screw extruder with an aspect ratio of 40. The obtained separator is designated as S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com