Micro-flow control chip machining and detection experiment device based on digital micro-mirror device

A digital micromirror device, microfluidic chip technology, applied in the direction of measuring devices, microstructure devices, manufacturing microstructure devices, etc., can solve the problem of inability to realize real-time detection of microchannel pattern soft lithography exposure, inability to realize rapid processing and Real-time detection and other problems to achieve the effect of shortening the preparation cycle, convenient modification, and overcoming insufficient precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

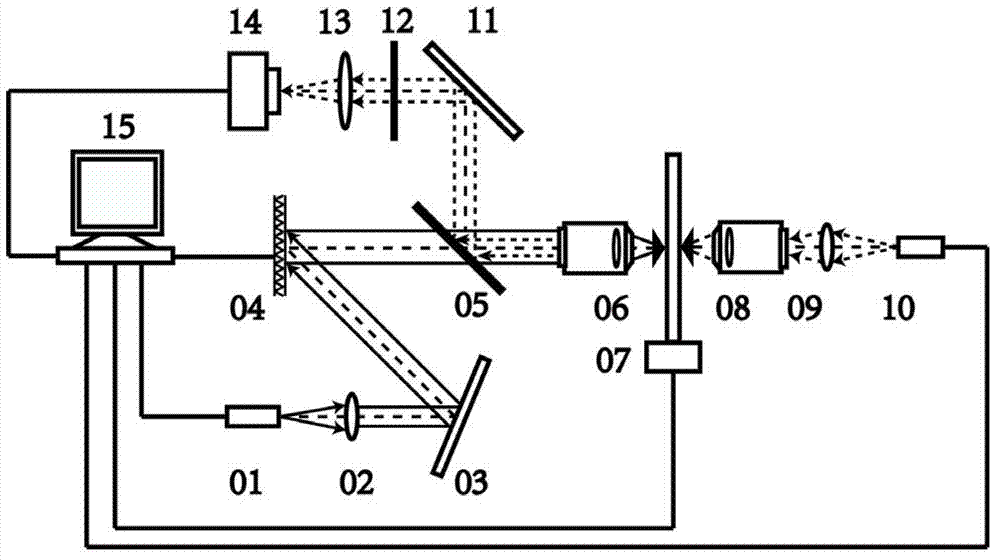

[0030] The specific embodiment of the present invention is the preferred embodiment of basic embodiment, specifically as follows:

[0031]In this embodiment, the wavelength of the emitted light of the ultraviolet LED light source 1 is 365nm, and the spectral line width is 7.5nm; membrane. An ultraviolet LED beam expanding light source is jointly formed by the ultraviolet LED light source 1 and the first lenticular lens 2 . The beam diameter of the light source after beam expansion is about 10mm.

[0032] The size of the DMD device 4 is about 10*10mm, the dichroic mirror 5 can transmit ultraviolet light and reflect visible light; the first microscope objective lens 6 has a magnification of 10X, an effective focal length of 20mm, and is coated with a 325-500nm near-ultraviolet anti-reflection film . The DMD device 4, the dichroic mirror 5 and the first microscope objective lens 6 jointly constitute an image projection optical path.

[0033] The light wavelength produced by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com