Super-hard wear-resisting chromium-based compound coating micro drill bit for PCB (Printed Circuit Board) and preparation method thereof

A composite coating, composite layer technology, applied in the direction of coating, metal material coating process, layered products, etc., can solve the problem of low hardness of CrN coating, achieve low friction coefficient, reduce easy fracture, hardness and toughness improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

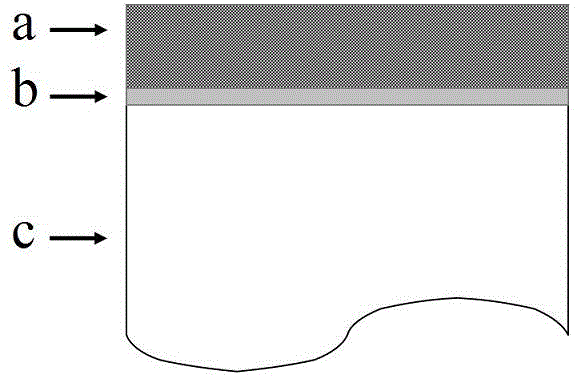

Image

Examples

Embodiment 1

[0022] Firstly, take the PCB micro-drill of 0.4-0.6mm as the standard test sample of cemented carbide, and deposit the coating on the PCB micro-drill after degreasing, organic cleaning, rinsing and plasma cleaning. First set the temperature of the cemented carbide substrate (that is, the micro-drill to be deposited coating) at 200 o C, after the deposition process is set, it is controlled by the industrial computer. The substrate pulse bias frequency is 80KHz, the bias peak value is -800V, the duty cycle is 40%, the Ar flow rate is 40ml / min, the ion-plating Cr target is turned on, the arc current is set to 70A, and Cr ions are evaporated from the Cr target. The alloy substrate was bombarded and cleaned for 1 min; then the pulse bias was adjusted to the peak value -500V, the duty cycle was 40%, the Ar flow rate was 20ml / min, and the N 2 The flow rate is 200ml / min, and the ion-plating Cr target current is maintained at 60A. At this stage, Cr ions react with nitrogen to form CrN...

Embodiment 2

[0024] Take the hard alloy standard test sample with a diameter of 0.8-1.2mm PCB micro-drill, and deposit the coating after degreasing, organic cleaning, rinsing and plasma cleaning. The cemented carbide substrate temperature is set to 250 oC, after the deposition process is set, it is controlled by the industrial computer. The pulse bias frequency of the cemented carbide substrate is 80KHz, the bias peak value is -800V, the duty cycle is 40%, the Ar flow rate is 40ml / min, the ion-plating Cr target is turned on, the arc current is 70A, and the Cr ions are evaporated from the Cr target. The alloy substrate was bombarded and cleaned for 1 min; then the pulse bias was adjusted to the peak value -600V, the duty cycle was 40%, the Ar flow rate was 30ml / min, and the N 2 The flow rate is 300ml / min, and the ion-plating Cr target current is maintained at 70A. At this stage, Cr ions react with nitrogen to form CrN, thereby depositing a transition layer of CrN on the cemented carbide su...

Embodiment 3

[0026] Take a PCB micro-drill with a diameter of 1.3-2mm as a standard test sample of cemented carbide, and deposit a coating after degreasing, organic cleaning, rinsing and plasma cleaning. The cemented carbide substrate temperature is set to 300 o C, after the deposition process is set, it is controlled by the industrial computer. The substrate pulse bias frequency is 80KHz, the bias peak value is -800V, the duty cycle is 40%, the Ar flow rate is 40ml / min, the ion-plating Cr target is opened, the arc current is 70A, the Cr ions are evaporated from the Cr target, and the cemented carbide substrate is Bombardment cleaning for 1min; pulse bias adjusted to peak value -700V, duty cycle 40%, Ar flow rate 40ml / min, N 2 The flow rate is 400ml / min, and the ion-plating Cr target current is maintained at 80A. At this stage, Cr ions react with nitrogen to form CrN, thereby depositing a transition layer of CrN on the cemented carbide substrate, and plating CrN for 15 minutes; close the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com