Scenedesmus sp., CHX1 and use thereof

A technology for Scenedesmus and seeds is applied in the application field of Scenedesmus in the fields of bioenergy and purifying swine wastewater, which can solve the problems of low oil yield, low biological yield and high requirements for cultivation conditions, and achieves high oil yield and biological The effect of high yield and low requirements for culture conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

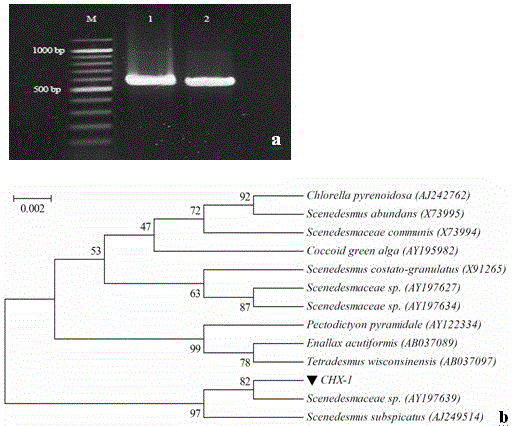

[0020] Example 1 Isolation and identification of Scenedesmus CHX1

[0021] 1. Sample collection

[0022] In July 2011, it was collected from a wastewater pond of a farm in Xiaoshan District, Hangzhou City, Zhejiang Province containing

[0023] Water sample of green algae.

[0024] 2. Isolation and purification of Scenedesmus CHX1

[0025] Separation and purification steps: Centrifuge and concentrate the collected water samples (5000 r / min, 4°C), dilute with sterile water, pass through a 60-micron mesh protozoan sieve, and then pass through a 0.45-μm filter membrane. Rinse the filter membrane several times with sterile water, transfer the remaining cells on the filter membrane to a 12-well cell culture plate (each well contains 1ml of sterilized BG-11 culture solution, and the sterilization method is high-pressure steam sterilization at 121°C 20 minutes), placed in a light incubator for enrichment culture (the culture condition is light all day long, and the light intensit...

Embodiment 2

[0037] Example 2 Optimization of Growth Conditions of Scenedesmus CHX1

[0038] 1. Determination of Optimal Absorbance Density Value of Scenedesmus CHX1

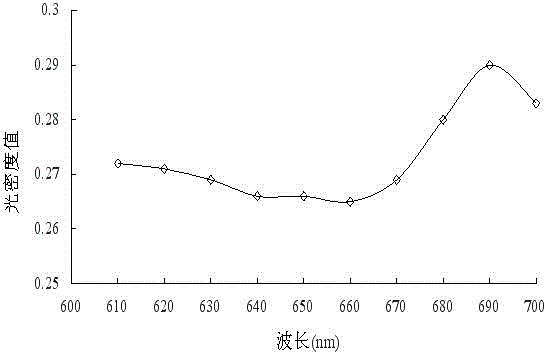

[0039] In order to better describe the growth of Scenedesmus CHX1 and determine the optimal absorbance value of Scenedesmus CHX1, the BG11 culture solution containing microalgae was scanned automatically in the range of 600-700nm. Scan results see figure 2 .

[0040] 2. Optimization and determination of the growth conditions of Scenedesmus CHX1

[0041] In order to make Scenedesmus CHX1 grow faster and better, the combination of culture mode, carbon source, glucose dosage and culture conditions was optimized on the basis of BG-11 medium.

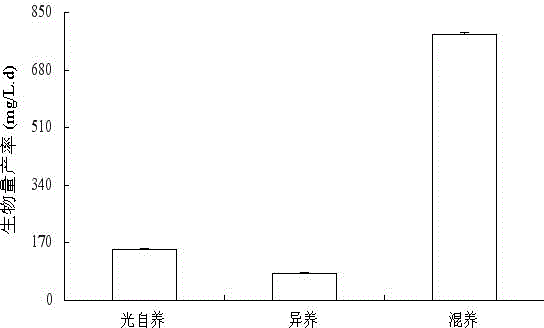

[0042] 1. Optimal determination of culture methods

[0043] Based on the BG-11 medium, three culture methods were set up: photoautotrophic, heterotrophic and polytrophic. The photoautotrophic culture condition was light + BG-11 culture medium; the heterotrophic culture condition was...

Embodiment 3

[0054] Example 3 Growth and oil production of Scenedesmus CHX1

[0055] 1. Cultivation of Scenedesmus CHX1

[0056] Cultivate Scenedesmus CHX1 according to the optimized conditions and medium in Example 2, the culture temperature is 25°C, and the light is 40 μmol photon / m all day long 2 .s conditions for 3 days.

[0057] 2. Determination of Growth and Oil Production of Scenedesmus CHX1

[0058] 1. Biomass determination of Scenedesmus CHX1

[0059] Take the culture solution and place it in a centrifuge tube, centrifuge for 10 min (10000 r / min, 4 °C), discard the supernatant, transfer the concentrated biomass to tin foil, and freeze-dry. 2.44g of dry algae were obtained per liter of culture solution (the average biomass yield was 814.1 mg / L.d, and the range was 809.6~818.6 mg / L.day), and the biomass yield was relatively high.

[0060] 2. Determination of oil yield of Scenedesmus CHX1

[0061] Weigh a certain quality freeze-dried algae sample (weight W 0 ), add sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com