Hydrothermal liquid phase preparation method of magnetic kaolinite/chitosan composite

A technology of composite materials and kaolinite, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems such as separation and recovery difficulties, and achieve separation and recovery difficulties and good adsorption efficiency , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

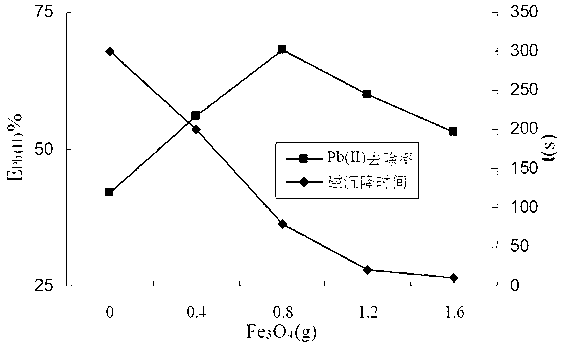

Embodiment 1

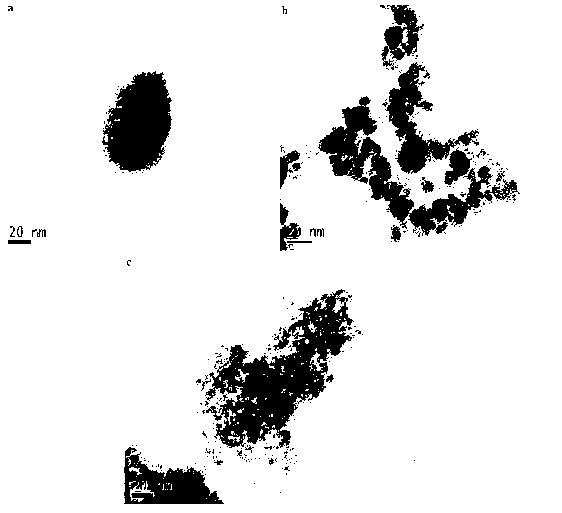

[0018] Synthesis of Magnetic Kaolinite

[0019] Add 0.4 g of magnetic ferric oxide suspension directly to a three-necked flask containing 2 g of kaolinite suspension aqueous solution with a mass ratio of 2%, and simultaneously add 80 mL of hydrogen with a mass ratio of 10% (sodium hydroxide / water) Sodium oxide solution, stirred vigorously at room temperature for 3 h, stopped stirring, washed the reaction solution with distilled water until neutral, centrifuged, and separated by suction filtration, dried the filter cake in a vacuum drying oven at 30°C for 12 hours, took it out, and ground To powder, to obtain magnetic kaolinite.

[0020] Preparation of Magnetic Kaolinite / Chitosan Composite

[0021] 2% (acetic acid / water) acetic acid aqueous solution of 2% chitosan was gradually added dropwise at a rate of 1.5 mL / min into a suspension containing 2 g mass ratio of 2% magnetic kaolinite using a constant pressure dropping funnel. solution in a 500 mL three-necked round-bottomed f...

Embodiment 2

[0023] Synthesis of Magnetic Kaolinite

[0024] Add 0.8g of magnetic ferric oxide suspension solution directly into a three-neck flask containing 2 g of kaolinite suspension solution with a mass ratio of 2%, and simultaneously add 80 mL of hydrogen with a mass ratio of 10% (sodium hydroxide / water) Sodium oxide solution, stirred vigorously at room temperature for 3 h, stopped stirring, washed the reaction solution with distilled water until neutral, centrifuged, and separated by suction filtration, dried the filter cake in a vacuum drying oven at 30°C for 12 hours, took it out, and ground To powder, to obtain magnetic kaolinite.

[0025] Preparation of Magnetic Kaolinite / Chitosan Composite

[0026] 2% (acetic acid / water) acetic acid aqueous solution of 2% chitosan was gradually added dropwise at a rate of 1.5 mL / min into a suspension containing 2 g mass ratio of 2% magnetic kaolinite using a constant pressure dropping funnel. solution in a 500 mL three-necked round-bottomed f...

Embodiment 3

[0028] Synthesis of Magnetic Kaolinite

[0029] Add 1.2 g of magnetic ferric oxide suspension directly into a three-necked flask containing 2 g of kaolinite suspension with a mass ratio of 2%, and simultaneously add 80 mL of hydrogen with a mass ratio of 10% (sodium hydroxide / water) Sodium oxide solution, stirred vigorously at room temperature for 3 h, stopped stirring, washed the reaction solution with distilled water until neutral, centrifuged, and separated by suction filtration, dried the filter cake in a vacuum drying oven at 30°C for 12 hours, took it out, and ground To powder, to obtain magnetic kaolinite.

[0030] Preparation of Magnetic Kaolinite / Chitosan Composite

[0031] A 2% (acetic acid / water) acetic acid aqueous solution of 2% chitosan was gradually added dropwise at a rate of 1.5 mL / min into a suspension containing 2 g of 2% magnetic kaolinite using a constant pressure dropping funnel. solution in a 500 mL three-necked round-bottomed flask, stirred at 36°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com