Preparation method of strontium-titanate hollow nanorod array

A technology of hollow nanometer and strontium titanate, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high cost and complicated preparation process, and achieve the effect of low cost, simple process and easy large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of the strontium titanate hollow nanorod array is operated according to the following steps:

[0020] (1) Prepare a mixed solution of ammonium fluorotitanate, strontium nitrate and boric acid, control the concentration ratio to 1:1:3, in which the concentration of ammonium fluorotitanate solution is 0.025mol / L, heat the reaction solution and keep it at a constant temperature of 40° C;

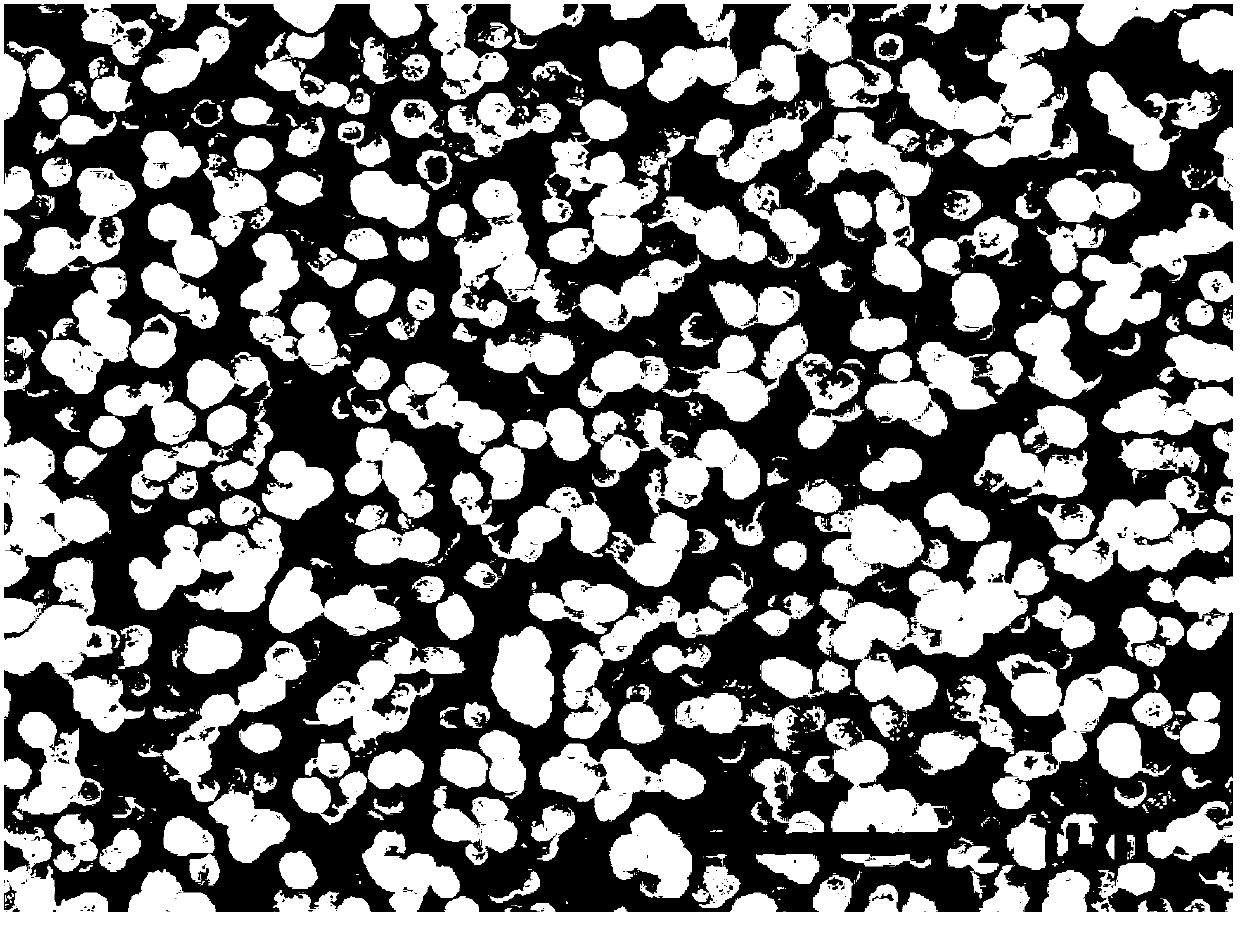

[0021] (2) Put the substrate with zinc oxide nanorod arrays into the reaction solution and let it stand for 60 minutes to perform SrTiO 3 The deposition of zinc oxide nanorod arrays is based on a glass sheet, the diameter of the nanorods is 130nm, and the length is 1μm, which is prepared by a conventional solution method;

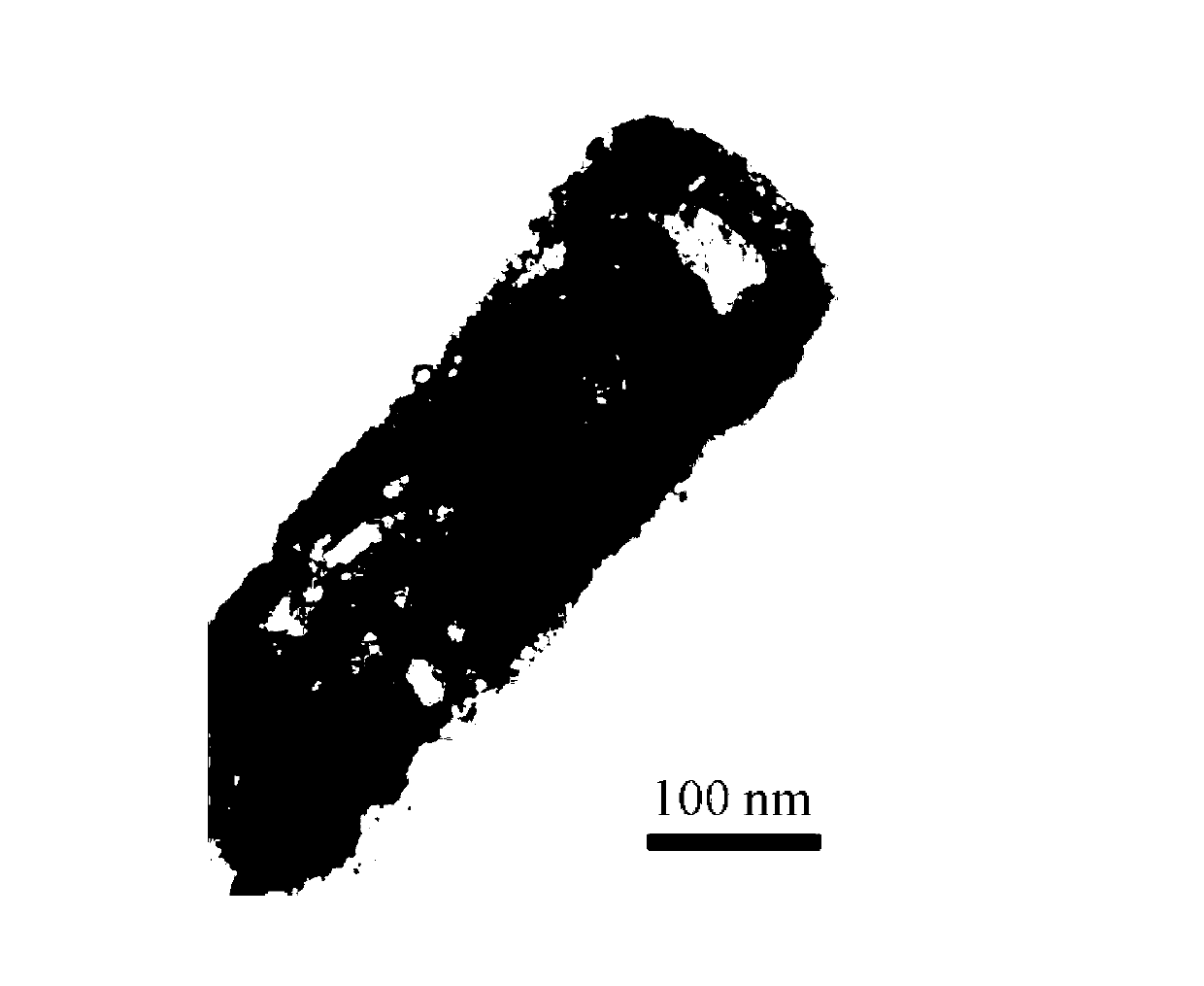

[0022] (3) Take out the substrate, wash and dry it, put it into a heat treatment furnace for annealing at 700°C for 1 hour, and the strontium titanate hollow nanorod array is prepared.

[0023] The finished product that embodiment 1 is made ut...

Embodiment 2

[0025] The preparation method of the strontium titanate hollow nanorod array is operated according to the following steps:

[0026] (1) Prepare a mixed solution of ammonium fluorotitanate, strontium nitrate and boric acid, control the concentration ratio to 1:1:4, in which the concentration of ammonium fluorotitanate solution is 0.05mol / L, heat the reaction solution and keep it at a constant temperature of 40° C;

[0027] (2) Put the substrate with zinc oxide nanorod arrays into the reaction solution and let it stand for 20 minutes to perform SrTiO 3 The deposition of zinc oxide nanorod arrays is based on a glass sheet, the diameter of the nanorods is 200nm, and the length is 2μm, which is prepared by a conventional solution method;

[0028] (3) Take out the substrate, wash and dry it, put it into a heat treatment furnace for annealing at 500°C for 2 hours, and the strontium titanate hollow nanorod array is prepared.

Embodiment 3

[0030] The preparation method of the strontium titanate hollow nanorod array is operated according to the following steps:

[0031] (1) Prepare a mixed solution of ammonium fluorotitanate, strontium nitrate and boric acid, control the concentration ratio to 1:1:4, in which the concentration of ammonium fluorotitanate solution is 0.1mol / L, heat the reaction solution and keep it at a constant temperature of 30° C;

[0032] (2) Put the substrate with zinc oxide nanorod arrays into the reaction solution and let it stand for 5 minutes to perform SrTiO 3 The deposition of ZnO nanorod arrays is based on a glass sheet, the diameter of the nanorods is 100nm, and the length is 1.5μm, which is prepared by a conventional solution method;

[0033] (3) Take out the substrate, wash and dry it, put it into a heat treatment furnace for annealing at 800°C for 1 hour, and the strontium titanate hollow nanorod array is prepared.

[0034] The invention provides a method for preparing SrTiO by us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com