Synthesis method of tungsten trioxide

A tungsten trioxide and synthesis method technology, applied in the direction of tungsten oxide/tungsten hydroxide, etc., can solve the problems of many operation steps and low degradation efficiency, achieve good repeatability, high photodegradation efficiency, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Weigh 0.825g of sodium tungstate dihydrate and 0.29g of sodium chloride respectively, and add them into 75mL of water so that the concentration of sodium tungstate dihydrate in water is 0.033mol / L. Ultrasound for 5min, under magnetic stirring, Use hydrochloric acid to adjust the pH value of the solution to 1.5, and continue stirring for 1 hour to obtain a precursor solution;

[0054] (2) Transfer the precursor solution to the reaction kettle, conduct a hydrothermal reaction at 180°C for 24 hours, and cool to room temperature naturally. The obtained product is washed with distilled water and absolute ethanol in turn, centrifuged and dried to obtain WO 3 Powder.

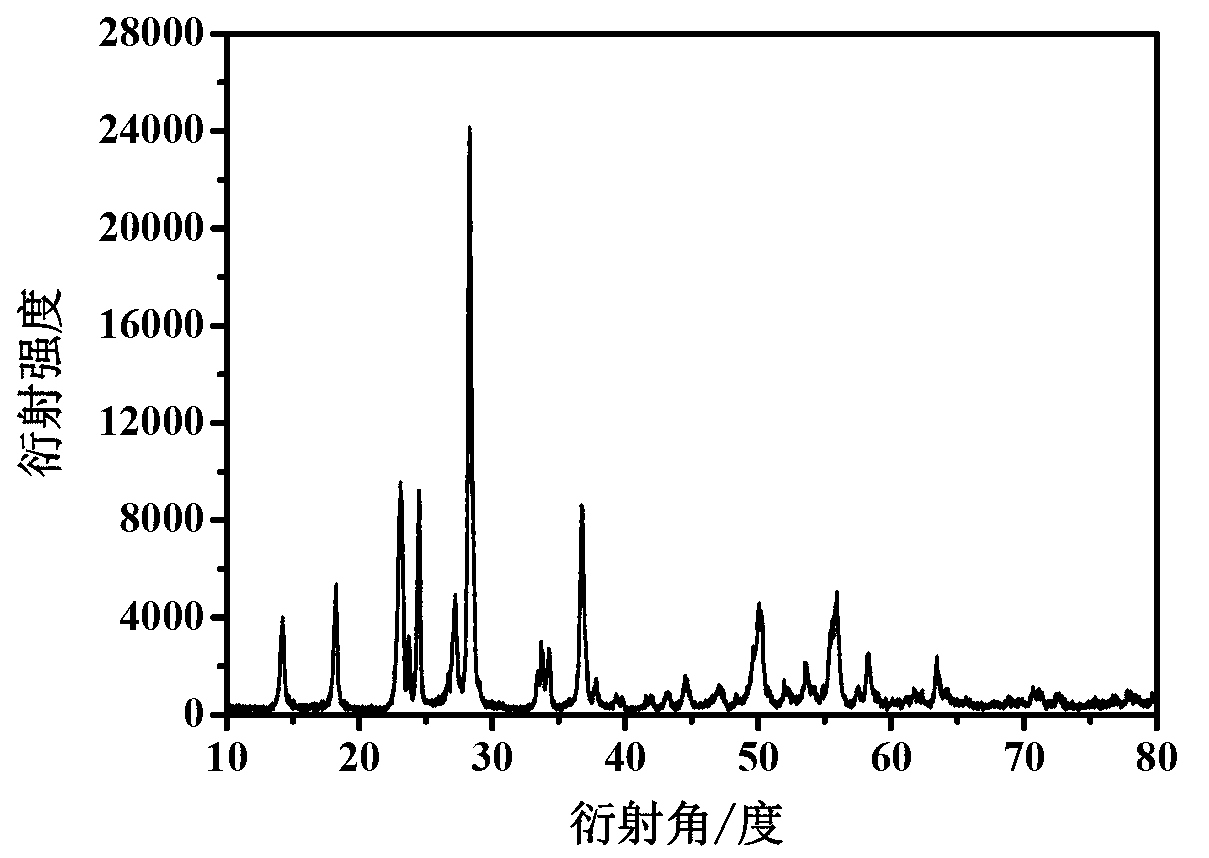

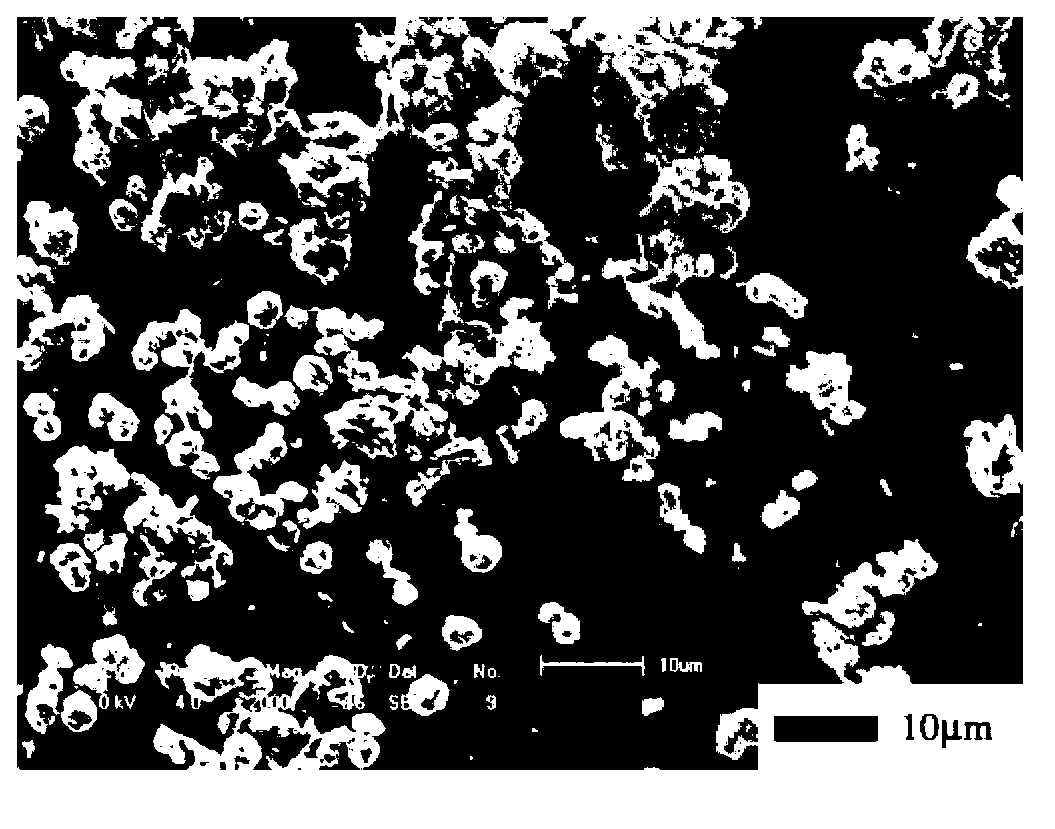

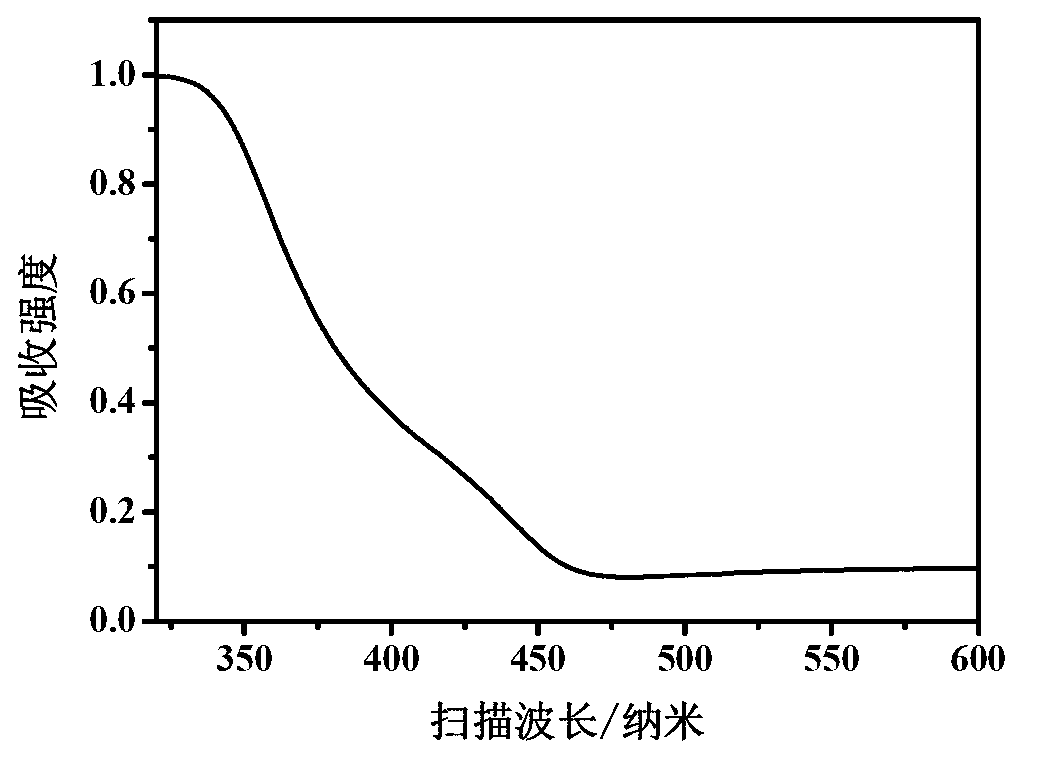

[0055] The synthetic WO of embodiment 1 3 X-ray diffraction pattern of powder (RigakuMax-2550 X-ray diffraction analyzer, XRD) see figure 1 , scanning electron micrograph (SEM, SHIMADZUSSX-550 scanning electron microscope) see figure 2 , UV-visible absorption spectrum (Shimadzu company UV-3600 UV-visible...

Embodiment 2

[0058] Adjust the pH value of the precursor solution to 2.1 to prepare WO 3 , the synthesis process is the same as in Example 1.

[0059] The synthetic WO of embodiment 2 3 For powder XRD see Image 6 , see SEM Figure 7 , see the UV-Vis absorption spectrum Figure 8 , the surface photovoltage spectrum is shown in Figure 9 , the photodegradation curve of catalytic degradation of RhB is shown in Figure 10 .

[0060] Depend on Figure 7 It can be seen that the WO obtained under the condition of pH=2.1 3 The shape of the disc is 6 μm in diameter and 2 μm in thickness, with a porous structure; Figure 8 with Figure 9 Visible, the WO 3 With visible light response characteristics, the absorption of visible light extends to 460nm, and the maximum light response intensity is about 60μV; by Figure 10 Visible to WO 3 powder as a catalyst, when WO 3 When the dosage is 0.02g, 20mL RhB with a concentration of 10mg / L is catalytically degraded, and RhB is degraded by 90% whe...

Embodiment 3

[0062] Adjust the pH value of the precursor solution to 3.0 to prepare WO 3 , the synthesis process is the same as in Example 1.

[0063] The synthetic WO of embodiment 3 3 For powder XRD see Figure 11 , see SEM Figure 12 , see the UV-Vis absorption spectrum Figure 13 , the surface photovoltage spectrum is shown in Figure 14 , the photodegradation curve of catalytic degradation of RhB is shown in Figure 15 .

[0064] Depend on Figure 11 It can be seen that when the pH of the precursor is 3, WO 3 For orthorhombic crystal form; by Figure 12 It can be seen that when the pH of the precursor is 3, the resulting WO 3 It has a uniform nanowire morphology with a length of about 10 μm; by Figure 13 with Figure 14 It can be seen that the sample has strong ultraviolet light response characteristics, and also has a weak response to visible light, and the response wavelength range to light is less than 440nm; Figure 15 Visible to WO 3 powder as a catalyst, when WO 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com