Hydro-thermal treatment method for electroplating sludge

A technology of electroplating sludge and hydrothermal treatment, applied in sludge treatment, water/sludge/sewage treatment, metallurgical wastewater treatment, etc., can solve problems such as human body and ecological environment impact, secondary pollution, easy loss, etc. The effect of reducing the rate, reducing the moisture content, and reducing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

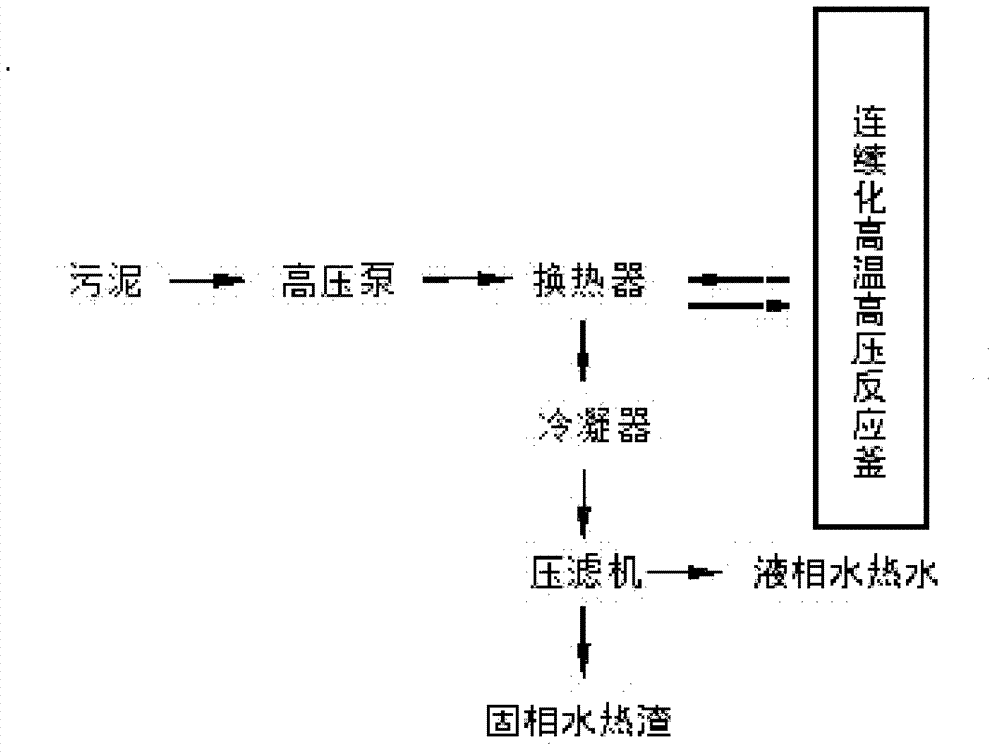

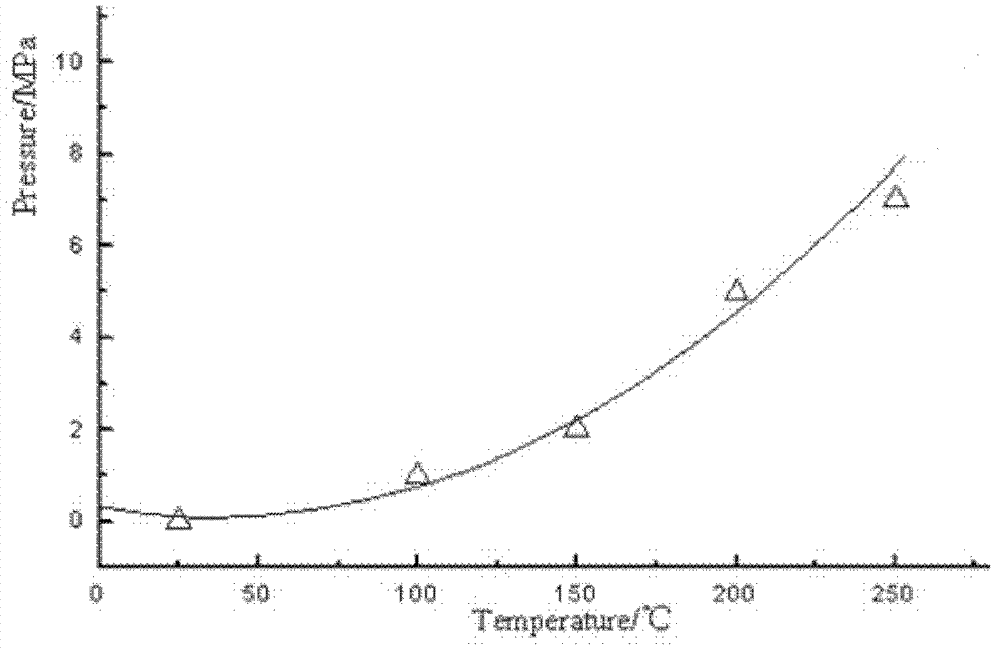

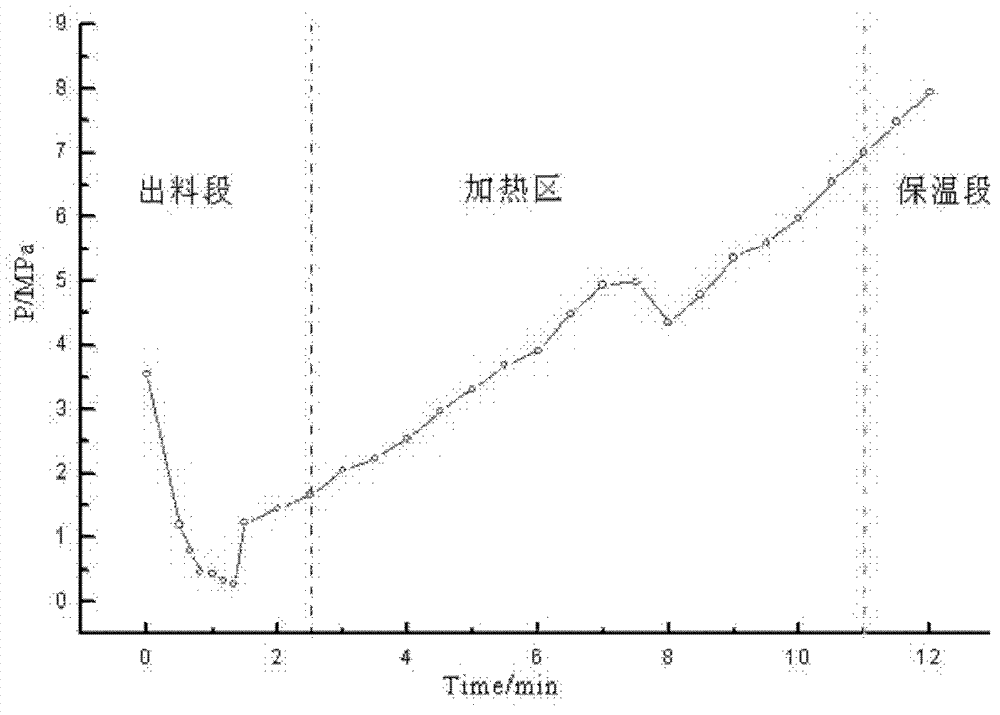

[0029] After the sludge truck is unloaded, put it into the tempering tank, add about 0.2 times the volume of aqueous solution to dilute it, and when it is in a fluid state, it is transported to the feed hopper by a screw conveyor, and then pumped into the sludge produced by Weihai Xintai Chemical Equipment Factory through a high-pressure feed pump. GSHA-1 permanent magnet rotary stirring autoclave, stop feeding after reaching a fixed capacity. Turn on the heating device of the GSHA-1 permanent magnet rotary stirring autoclave produced by Weihai Xintai Chemical Equipment Factory, heat and increase the pressure to 5.33MPa and 232°C, that is, open the GSHA-1 permanent magnet rotary autoclave produced by Weihai Xintai Chemical Equipment Factory The upper discharge valve of the stirring autoclave enters the residence tank, and the residence time is about 8 minutes. The lower discharge valve is opened to discharge the sludge to the storage tank by pressure pulse, and the discharged h...

Embodiment 2

[0035] After the sludge truck is unloaded, put it into the tempering tank, add about 0.2 times the volume of aqueous solution to dilute it, and when it is in a fluid state, it is transported to the feed hopper by a screw conveyor, and then pumped into the sludge produced by Weihai Xintai Chemical Equipment Factory through a high-pressure feed pump. GSHA-1 permanent magnet rotary stirring autoclave, stop feeding after reaching a fixed capacity. Turn on the heating device of the GSHA-1 permanent magnet rotary stirring autoclave produced by Weihai Xintai Chemical Equipment Factory, heat and increase the pressure to 7.67MPa and 241°C, that is, open the GSHA-1 permanent magnet rotary autoclave produced by Weihai Xintai Chemical Equipment Factory The upper discharge valve of the stirring autoclave enters the residence tank, and the residence time is about 8 minutes. The lower discharge valve is opened to discharge the sludge to the storage tank by pressure pulse, and the discharged h...

Embodiment 3

[0041] After the sludge truck is unloaded, put it into the tempering tank, add about 0.2 times the volume of aqueous solution to dilute it, and when it is in a fluid state, it is transported to the feed hopper by a screw conveyor, and then pumped into the sludge produced by Weihai Xintai Chemical Equipment Factory through a high-pressure feed pump. GSHA-1 permanent magnet rotary stirring autoclave, stop feeding after reaching a fixed capacity. Turn on the heating device of the GSHA-1 permanent magnet rotary stirring autoclave produced by Weihai Xintai Chemical Equipment Factory, heat and increase the pressure to 7.98MPa and 256°C, that is, open the GSHA-1 permanent magnet rotary autoclave produced by Weihai Xintai Chemical Equipment Factory The upper discharge valve of the stirring autoclave enters the residence tank, and the residence time is about 8 minutes. The lower discharge valve is opened to discharge the sludge to the storage tank by pressure pulse, and the discharged h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com