Production method of EA (Ester Aroma) flavoring liquor

A production method and seasoning wine technology, which is applied in the field of wine making, can solve the problems of not finding the production of seasoning wine, etc., and achieve the effect of full taste, harmonious aroma and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

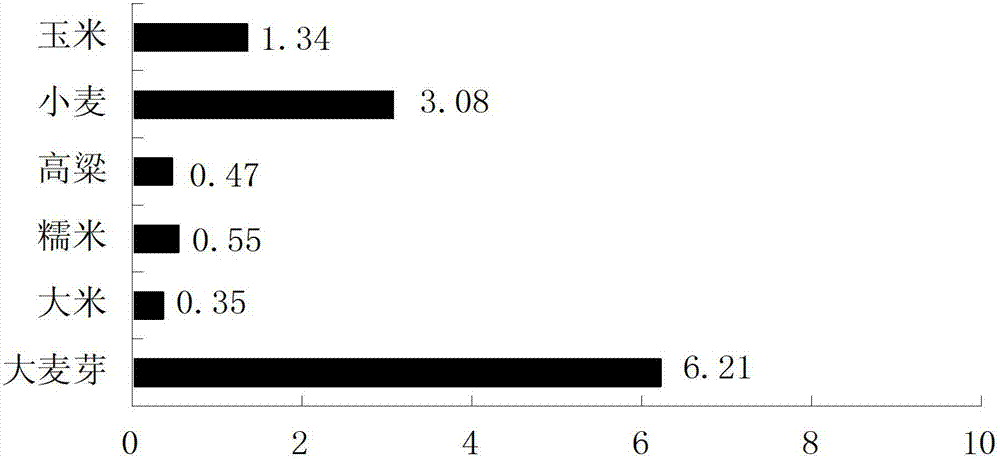

[0050] Specifically, the preparation method of the grain saccharification liquid includes the following steps: pulverize the grain raw materials to a fineness that can pass through a 20-mesh sieve (that is, the sieve 20 holes / cm 3 The content of fine powder in) accounts for 70-80% of the total grain; mix with water, the mass ratio of grain raw material to water is 1:4~1:5, adjust the pH to 5.0-7.0; add heat-resistant α-amylase to liquefy; The liquefaction is finished after adding the dilute standard solution and it does not turn blue; adjust the pH to 4.0-5.0, add saccharification enzyme for saccharification so that the glucose value reaches more than 95%, and the saccharification solution is obtained.

[0051] Specifically, the preparation method of the grain saccharification liquid includes the following steps: pulverize the grain raw materials, the pulverization fineness is such that the content of the fine powder that can pass through a 20-mesh sieve accounts for 70-80% of the ...

Embodiment 1

[0087] Example 1 Natural selection

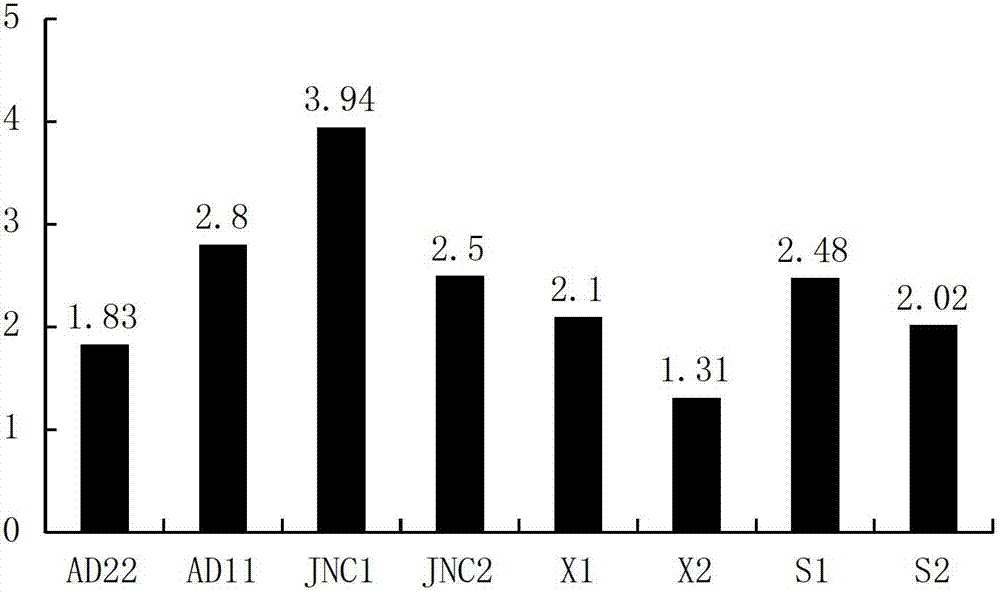

[0088] The following strains are all functional strains with high ethyl acetate production obtained from the separation and purification of koji and fermented grains of Jiannanchun Group Company. The specific process is as follows:

[0089] ①Sample collection:

[0090] Koji samples were collected for Luzhou-flavor Daqu with a storage period of 3 months, and 10 half pieces of Koji bricks (different storage rooms) were selected and crushed and mixed to obtain a comprehensive sample of Koji. The fineness of crushing is through 20 mesh sieve (ie sieve 20 holes / cm 3 ) The fine powder content accounts for 75% of the total amount of Qu medicine.

[0091] The middle and upper layer of high-quality mother glutinous grains (outcoming pit grains) are selected for the glutinous rice, and five points, namely the four corners and the central part of the glutinous rice, are taken, and each point is mixed with 200g as a sample of the glutinous rice. Randomly sel...

Embodiment 2

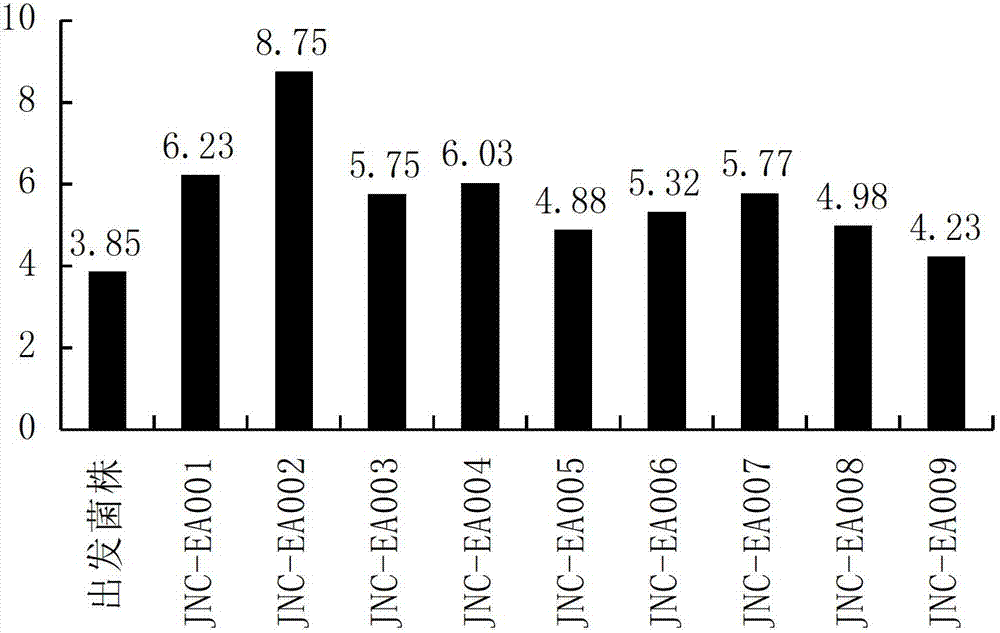

[0094] Example 2 Production performance test

[0095] The following parameters of the wort liquid medium used are: sugar content 12 (brix content, symbol: °Bx), diluted 4 times concentrated hydrochloric acid to adjust the pH to 3.4.

[0096] Preparation of bacterial suspension: Dip a sterile cotton swab with a little distilled water and let the cotton swab soak. Gently turn the cotton swab on the purified colony so that the cotton head is covered with bacteria. Quickly insert the cotton swab covered with bacteria into the turbidimetric tube containing 20 mL of sterile water. Rotate the cotton swab to disperse the bacteria in the sterile water, from the inside to the outside, from slow to fast, and pull out the cotton swab. Put the bacterial suspension on a vortex shaker and shake it well, then insert it into the cell concentration meter. Continue to use this method or add sterile water to adjust the concentration of each bacterial suspension to 10 6 Pieces / mL.

[0097] Fermentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com