Aromatic condensed ring quinones compound positive pole material for one-class lithium secondary battery

A technology for lithium secondary batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of less than half of the utilization rate of carbonyl sites, difficulties in bulk electron transport, and inability to meet the requirements of high-rate charge and discharge. Achieve the effects of high working voltage, good cycle performance and improved energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

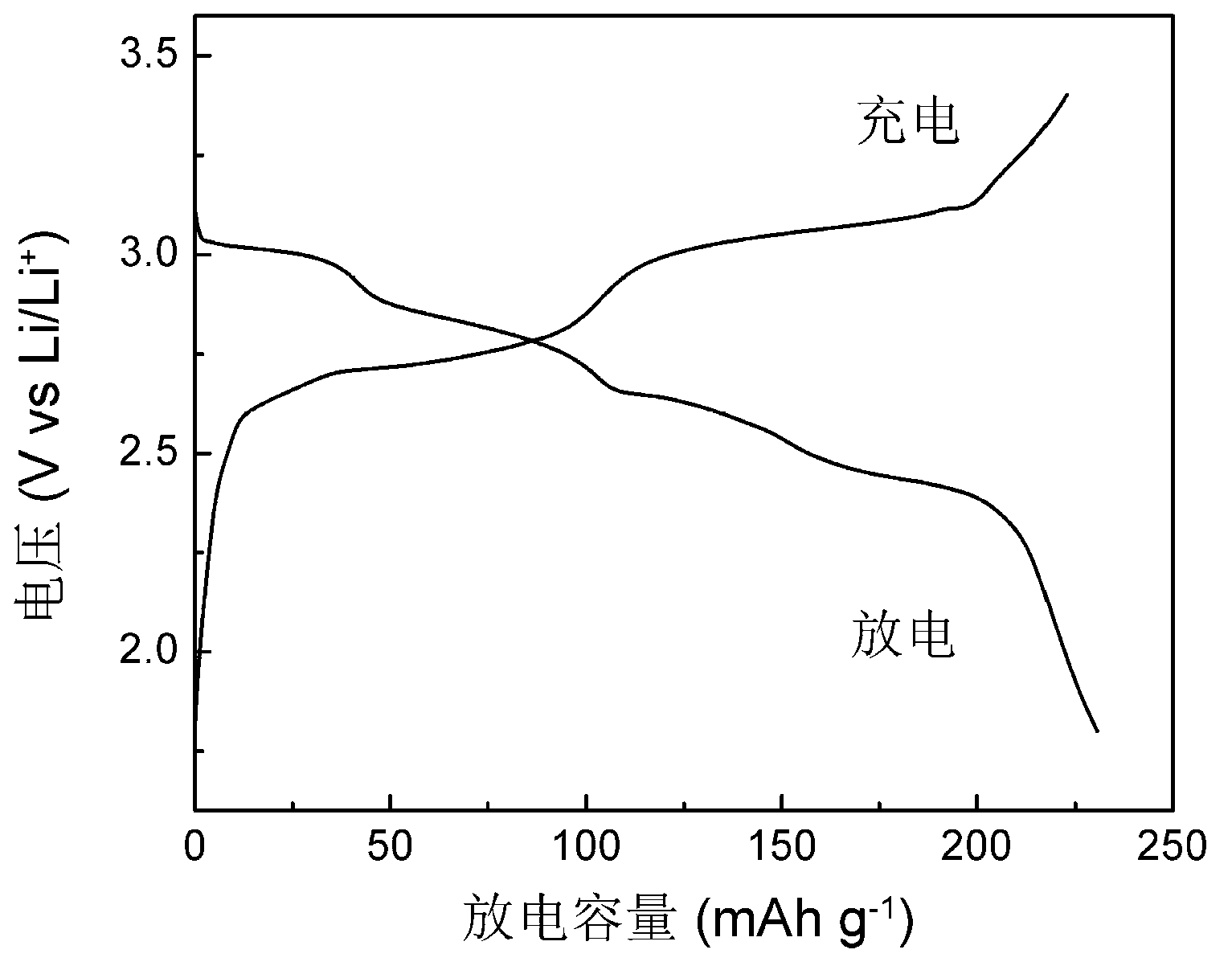

[0032] Grind 6mg of isobenzoquinone derivative A-10, 10mg of carbon black and 4mg of polyvinylidene fluoride into a slurry in 80μL of N-methylpyrrolidone, and evenly coat it on an aluminum foil with a diameter of 12mm, and then in -1MPa air, Dry at 343K for 3 hours and at 393K for 2 hours to make electrode sheets. In a glove box filled with argon gas, use the electrode sheet as the positive electrode, polyethylene / polypropylene / polyethylene three-layer film as the separator, and lithium hexafluorophosphate in a 1:1 volume ratio of ethylene carbonate and dimethyl carbonate mixed solvent 1mol / L solution is used as the electrolyte, and metal lithium is used as the negative electrode to assemble a lithium secondary battery. battery at 0.1C (26mA g -1 ) under constant current charge and discharge, the discharge voltage range is 1.8-3.4V. The first charge and discharge curve as figure 1 As shown, the first discharge capacity is 231mAh g -1 , the average discharge voltage is 2.7...

Embodiment 2

[0034] The synthesis of isobenzoquinone derivative PA-6 is shown in the following formula

[0035]

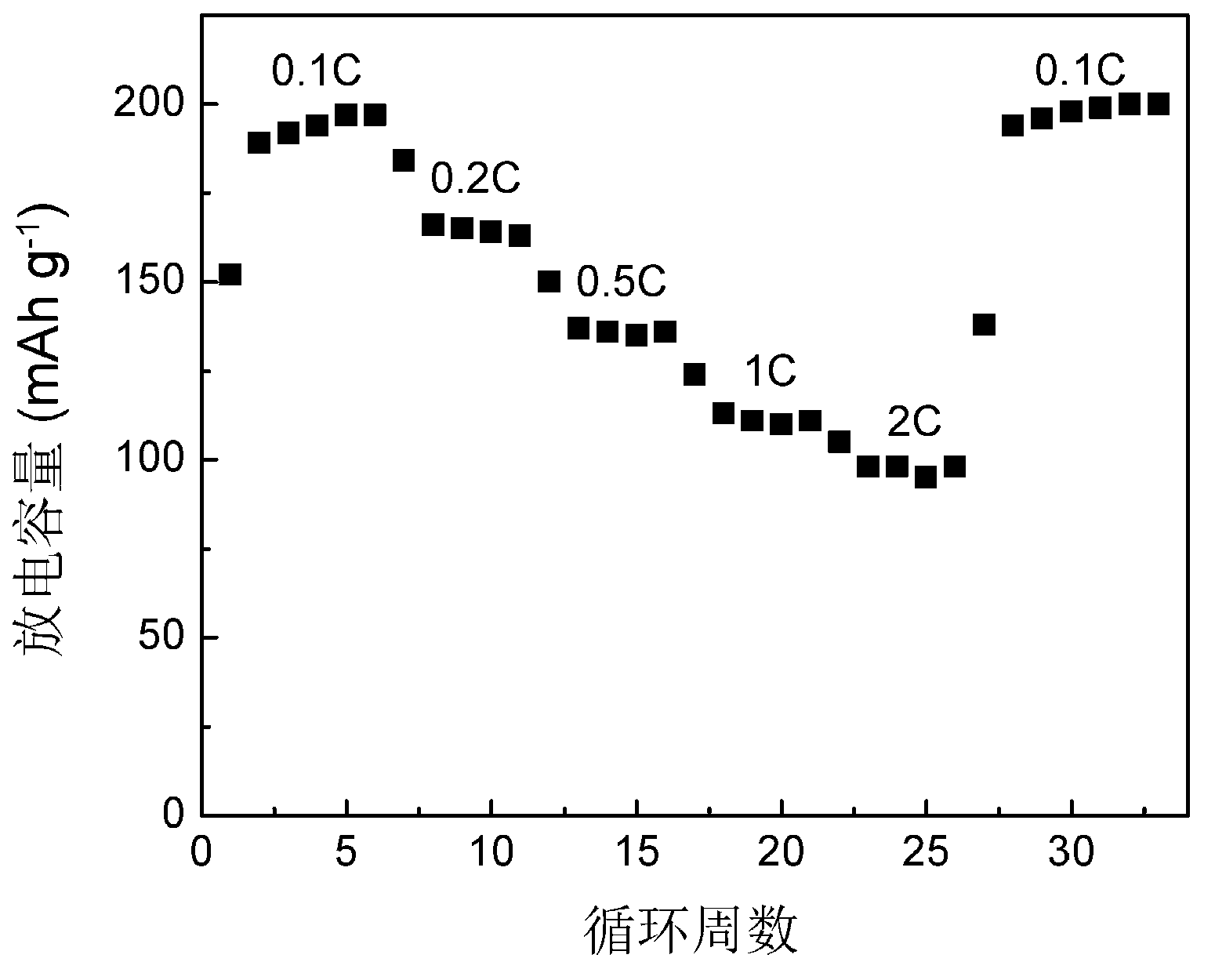

[0036] 3,8-Dibromophenanthroline on Ni(cod) 2 Under the action of reagents, polyphenanthroline is obtained by reduction polymerization, which is converted into PA-6 under mixed acid oxidation (the method is the same as the synthesis of A-10 above). Grind 10mg of PA-6, 10mg of carbon black and 5mg of polyvinylidene fluoride in 60μL of N-methylpyrrolidone evenly and coat it on aluminum foil, then dry it in 200Pa air at 393K for 4 hours to make an electrode sheet. The fabrication of the battery was the same as in Example 1. At 0.1-2C (26-510mAg -1 ) to charge and discharge the battery with a constant current, and the discharge voltage range is 1.8-3.6V. The cycle charge and discharge capacity retention curve is as follows figure 2 As shown, the discharge capacity at 0.1C reaches 197mAh g -1 , the average discharge voltage is 2.53V, half of the capacity can still be releas...

Embodiment 3

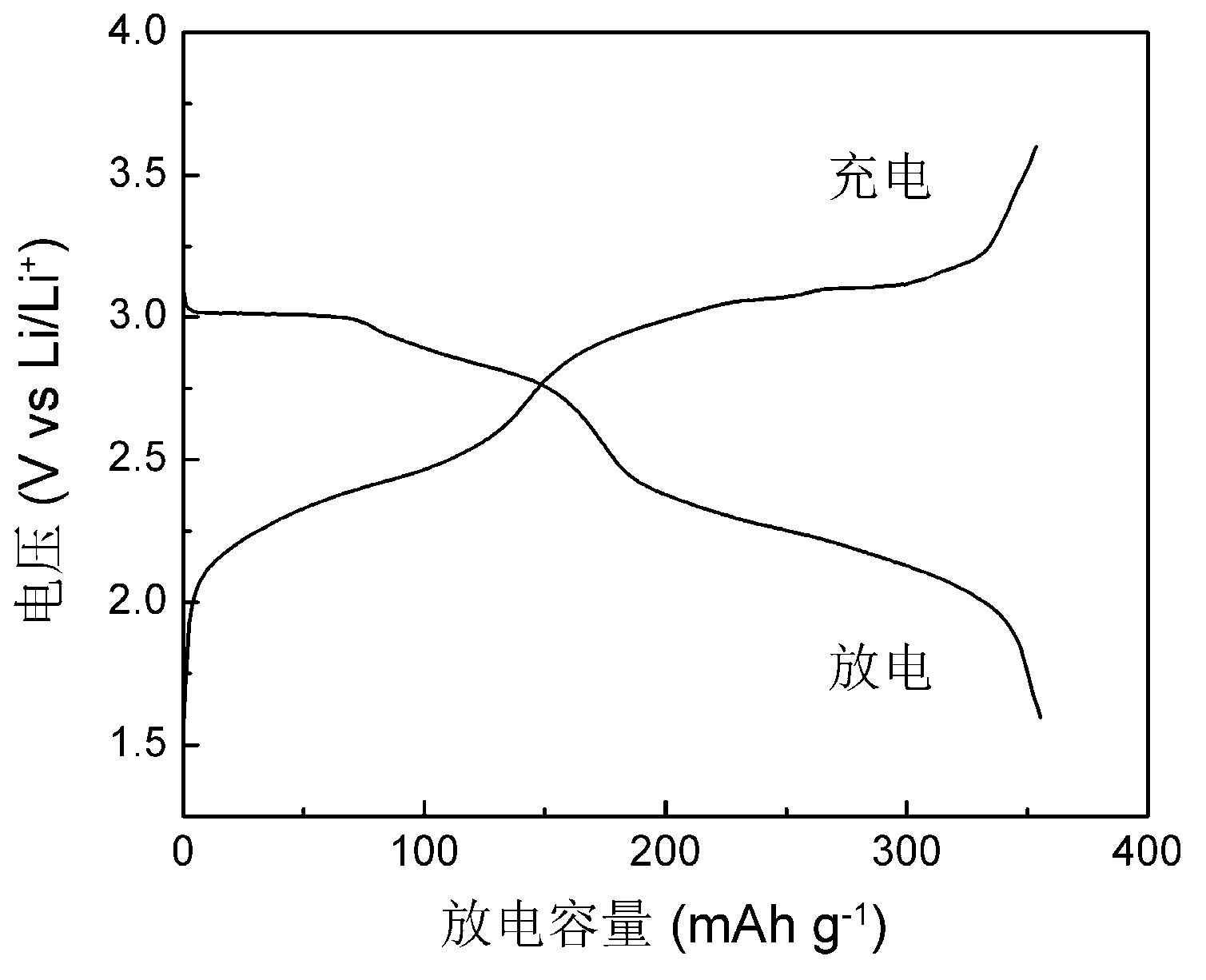

[0038] Grind 5 mg of isobenzoquinone derivative X-1 and 5 mg of carbon black in 60 μL of N-methylpyrrolidone evenly and coat it on an aluminum foil, then dry it in 150 Pa air at 343 K for 3 hours to make an electrode sheet. The fabrication of the battery was the same as in Example 1. on battery at 0.1C (41mA g -1 ) under constant current charge and discharge, the discharge voltage range is 1.6-3.6V. The first charge and discharge curve as image 3 As shown, the first discharge capacity is 360mAhg -1 , the average discharge voltage is 2.59V, and the energy density is 843Wh kg -1 , the first Coulombic efficiency is 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com