Preparation method and process for antibacterial modification of ceramic whiskers

A ceramic whisker and modification technology, which is applied in the direction of local antibacterial agents, resistance to vector-borne diseases, medical preparations containing active ingredients, etc., can solve the problems of inability to increase material strength and insignificant enhancement, and achieve surface area and roughness The effect of increased degree, improved mechanical fit, and good antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation method of the present invention:

[0030] A. Dissolve the zinc salt and complex compound with a mass ratio of 1:0 to 4:1 in absolute ethanol with stirring at 70°C to make a clear solution with a concentration of 0.04 to 0.08mol / L. This product is I;

[0031] B. The hydroxyapatite whiskers are evenly dispersed in the ethanol solution by ultrasonic vibration, and the product is II;

[0032] C. Under stirring, slowly add the product I dropwise to the product II, adjust the pH value to 4.8-8.2 with ammonia water, react at a constant temperature of 37°C-70°C for 4-8 hours, and then sonicate for 10-60 seconds; heat up to Evaporate the solvent to dryness at 78°C to 80°C, and place it in a thermostat to dry completely. The product is III;

[0033] D. Put the product III in an airtight container to roast, raise the temperature to 800°C-900°C at a rate of 2-5°C / min and keep it warm for 0.5-2 hours, then slowly cool down to room temperature with the container to obtai...

Embodiment 1

[0038] A. Dissolve zinc acetate in absolute ethanol with stirring at 70°C to make a clear solution with a concentration of 0.06mol / L;

[0039] B. Hydroxyapatite whiskers are evenly dispersed in ethanol solution by ultrasonic vibration;

[0040] C. Under stirring, slowly add the clear solution formed in step A into the dispersion formed in step B, adjust the pH to 4.8 with ammonia water, react at a constant temperature of 37°C for 6 hours, then ultrasonicate for 15 seconds, and raise the temperature to 78°C-80°C Evaporate the solvent to dryness at ℃, and place it in a constant temperature box to dry completely; put the product in a closed container and roast at a heating rate of 2°C to 5°C to 800°C and keep it warm for 1 hour, then slowly cool down to room temperature with the container, and a well-modified product is obtained. ZnO-hydroxyapatite whiskers.

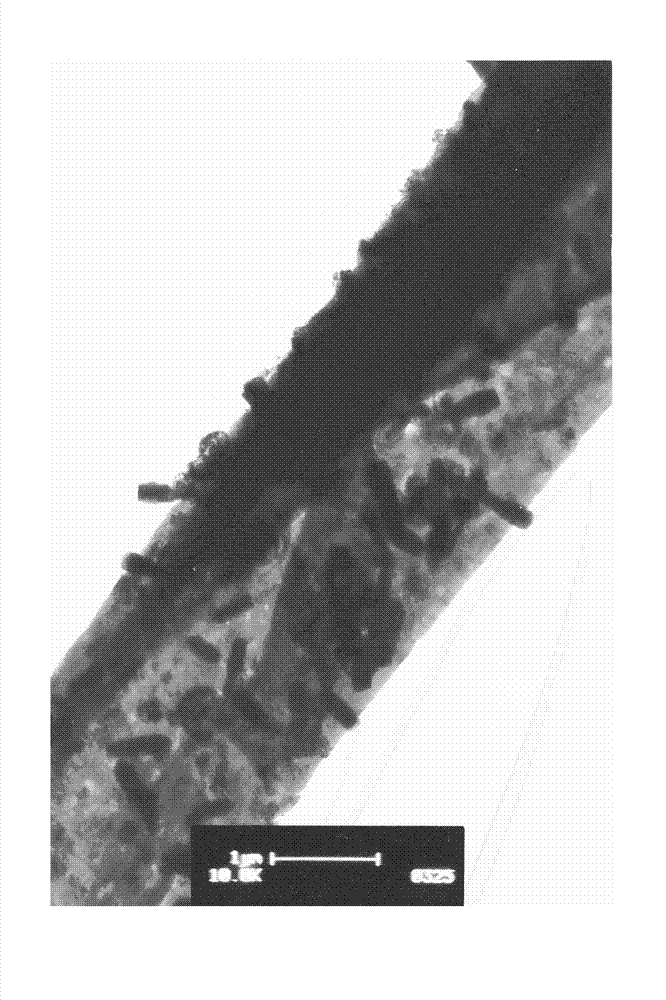

[0041] The results of transmission electron microscopy analysis are shown in figure 1 , a small amount of zinc oxide ba...

Embodiment 2

[0043] A. Dissolve zinc acetate in absolute ethanol with stirring at 70°C to make a clear solution with a concentration of 0.06mol / L;

[0044] B. Hydroxyapatite whiskers are evenly dispersed in ethanol solution by ultrasonic vibration;

[0045] C. Under stirring, slowly drop the clear liquid formed in step A into the dispersion liquid formed in step B, adjust the pH to 6.4 with ammonia water, react at a constant temperature of 37°C for 6 hours, then ultrasonicate for 15 seconds, and raise the temperature to 78°C-80°C Evaporate the solvent to dryness at ℃, and place it in a constant temperature box to dry completely; put the product in a closed container and roast at a heating rate of 2°C to 5°C to 800°C and keep it warm for 1 hour, then slowly cool down to room temperature with the container, and a well-modified product is obtained. ZnO-hydroxyapatite whiskers.

[0046] The results of transmission electron microscopy analysis are shown in figure 2 , the measured diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com