Production method of propylene

A production method and technology of propylene, applied in the field of propylene production, can solve the problems of low propylene yield and achieve the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] After mixing 100 grams of NaZSM-5 with a silicon-aluminum ratio of 900 and a small amount of extrusion aid, add alumina as a binder so that the weight ratio of alumina to the entire catalyst is 50%. After adjusting to a suitable humidity, extrude into strips with a diameter of 1 mm. After the sample was calcined at 600°C for 3 hours, it was exchanged with 5% ammonium nitrate solution at 90°C for 2 hours, and the exchange was repeated three times to obtain ammonium ion type ZSM-5, and the ammonium ion type sample was calcined at 550°C for 4 hours to obtain catalyst A.

[0023] After mixing 100 grams of NaZSM-5 with a silicon-aluminum ratio of 300 and a small amount of extrusion aid evenly, add silicon oxide as a binder so that the weight ratio of silicon oxide to the entire catalyst is 20%. After adjusting to a suitable humidity, squeeze into strips with a diameter of 1 mm. After the sample was calcined at 600°C for 3 hours, it was exchanged with 5% ammonium nitrate sol...

Embodiment 2~12

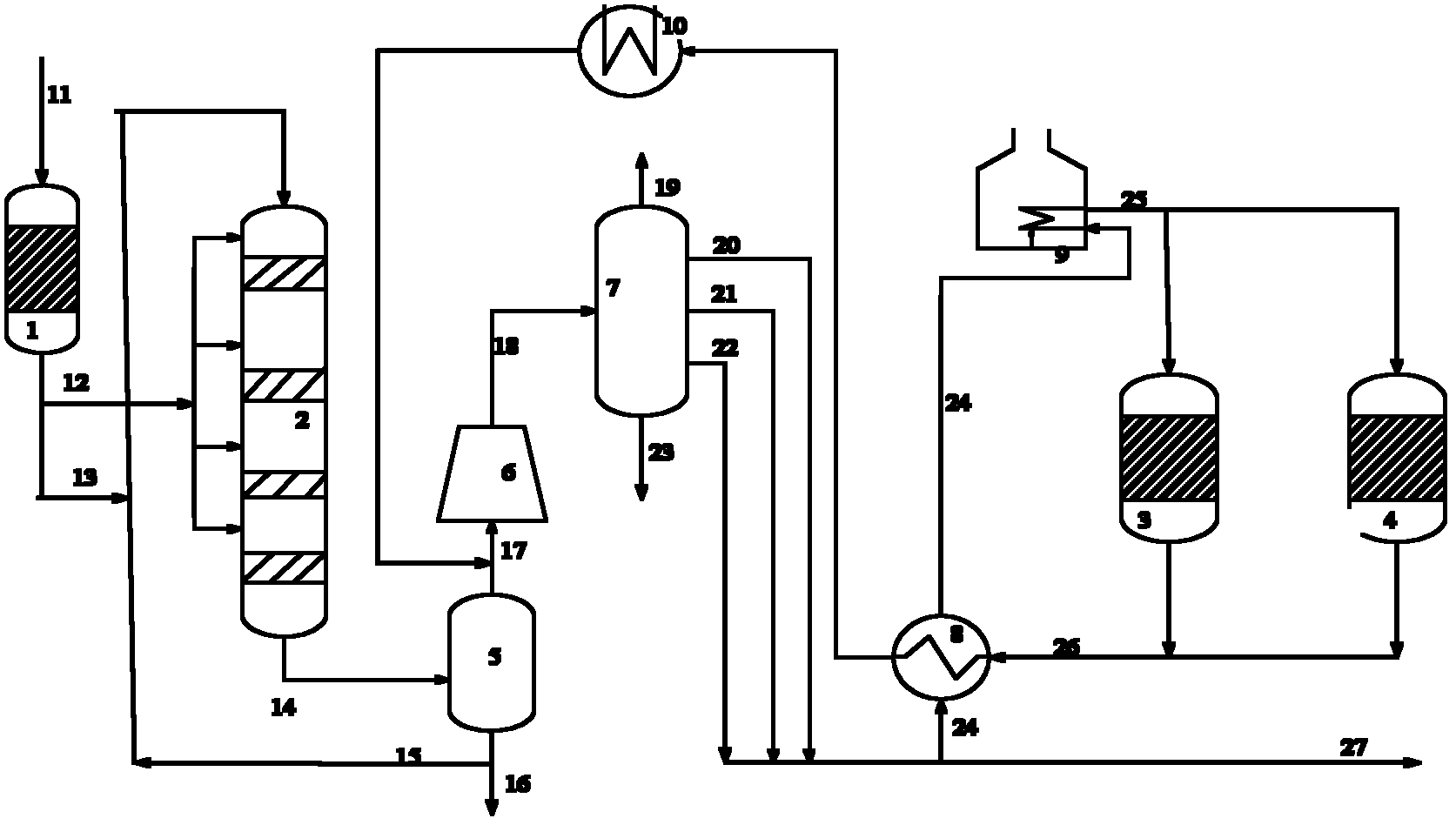

[0028] Change the operating parameter of reactor 3 by the condition of embodiment 1, adopt following steps to react:

[0029] (a) taking at least one of methanol and dimethyl ether as a raw material, contacting with molecular sieve catalyst A in reactor (1) to generate water, dimethyl ether and methanol effluent I; (b) effluent I in the reactor (2) contact with molecular sieve catalyst B again to generate effluent II containing propylene, ethylene, carbon four, carbon five and carbon six or more components; (c) after the effluent II enters the separation system to separate propylene, it will Ethylene, C4 and C5 by-products are sent into the reactor (3) to contact with molecular sieve catalyst C to generate propylene-containing stream III; (d) stream III is sent to the separation system to separate the product propylene, and the separated C2, C5 Four and carbon five are recirculated into the reactor (3) for reaction. The results are listed in Table 1.

[0030] Table 1

[003...

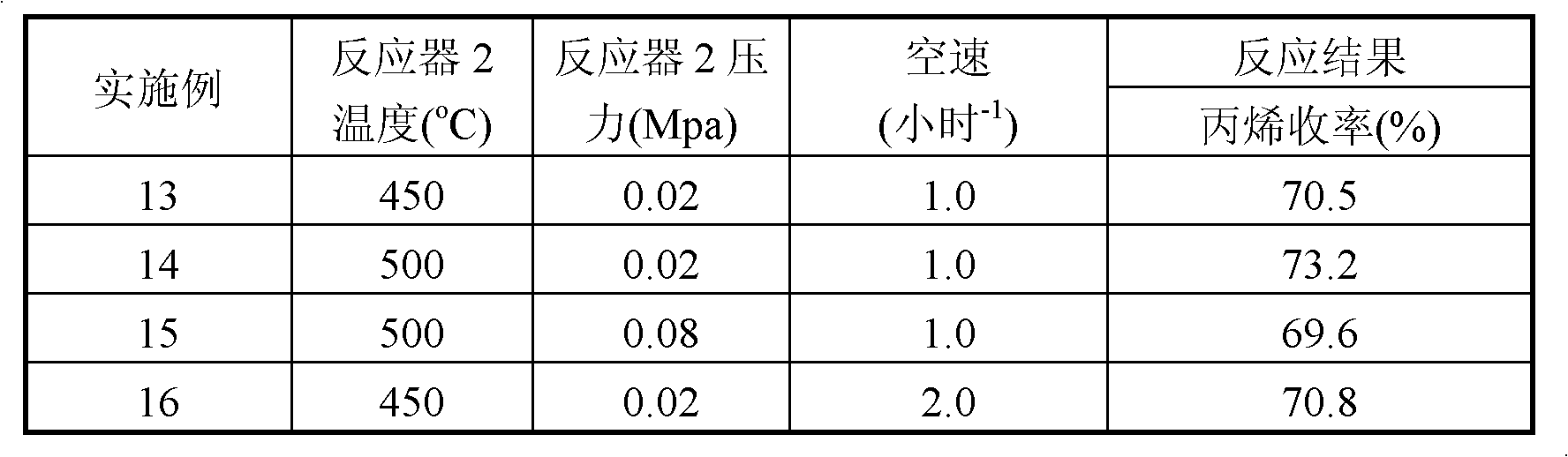

Embodiment 13~16

[0033] React according to the conditions and steps of Example 9, but change the operating parameters of Reactor 2, and the results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com