Method for preparing metal sodium through electrolysis

A metal sodium, electrolytic cell technology, applied in the direction of electrolysis process, electrolysis components, process efficiency improvement, etc., can solve the problems of corroded electron conduction, deposition, material cracking, etc., achieve high-efficiency and high-selectivity enrichment, and avoid harsh conditions , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

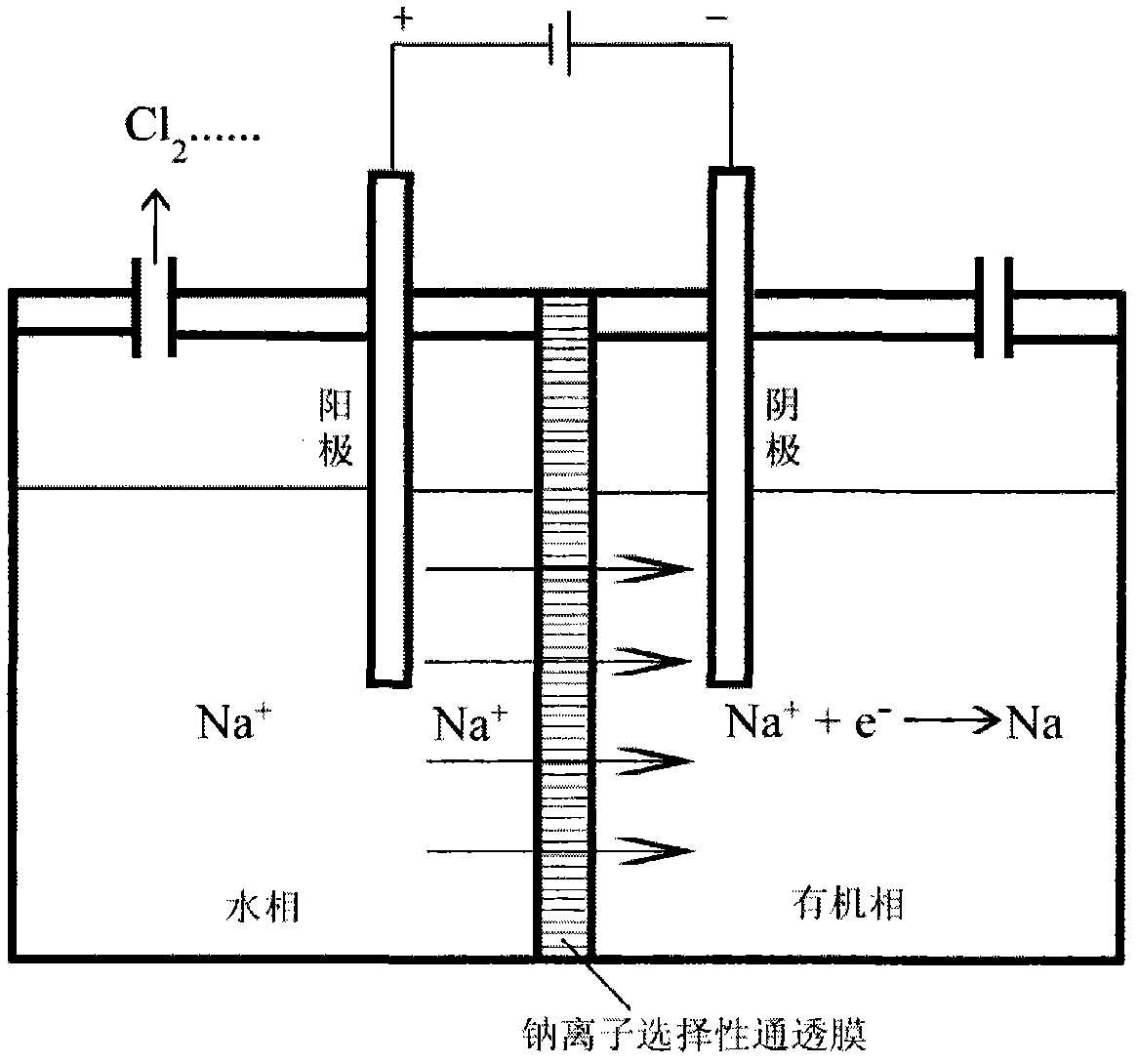

[0034] The preparation condition of metal sodium in the present invention is normal temperature and normal pressure, apply a certain DC voltage between the cathode and the anode, and the cathode is a negative potential, so as to realize the selective enrichment of sodium ions from the anode area to the cathode area and the concentration of sodium ions on the cathode. Electrolytic reduction; the reaction in the cathode area of the electrolytic cell is carried out under an inert gas protection atmosphere to prevent the entry of air and water.

[0035] The constituent materials of the electrolytic cell in the present invention are stainless steel, glass, polytetrafluoroethylene materials, etc.; the structure of the electrolytic cell is a bipolar chamber or a multipolar chamber, and the solution can flow between the electrode chambers; Metal electrodes, carbon electrodes, metal oxide electrodes or ceramic electrodes, such as nickel electrodes for cathodes and graphite electrodes ...

Embodiment 1

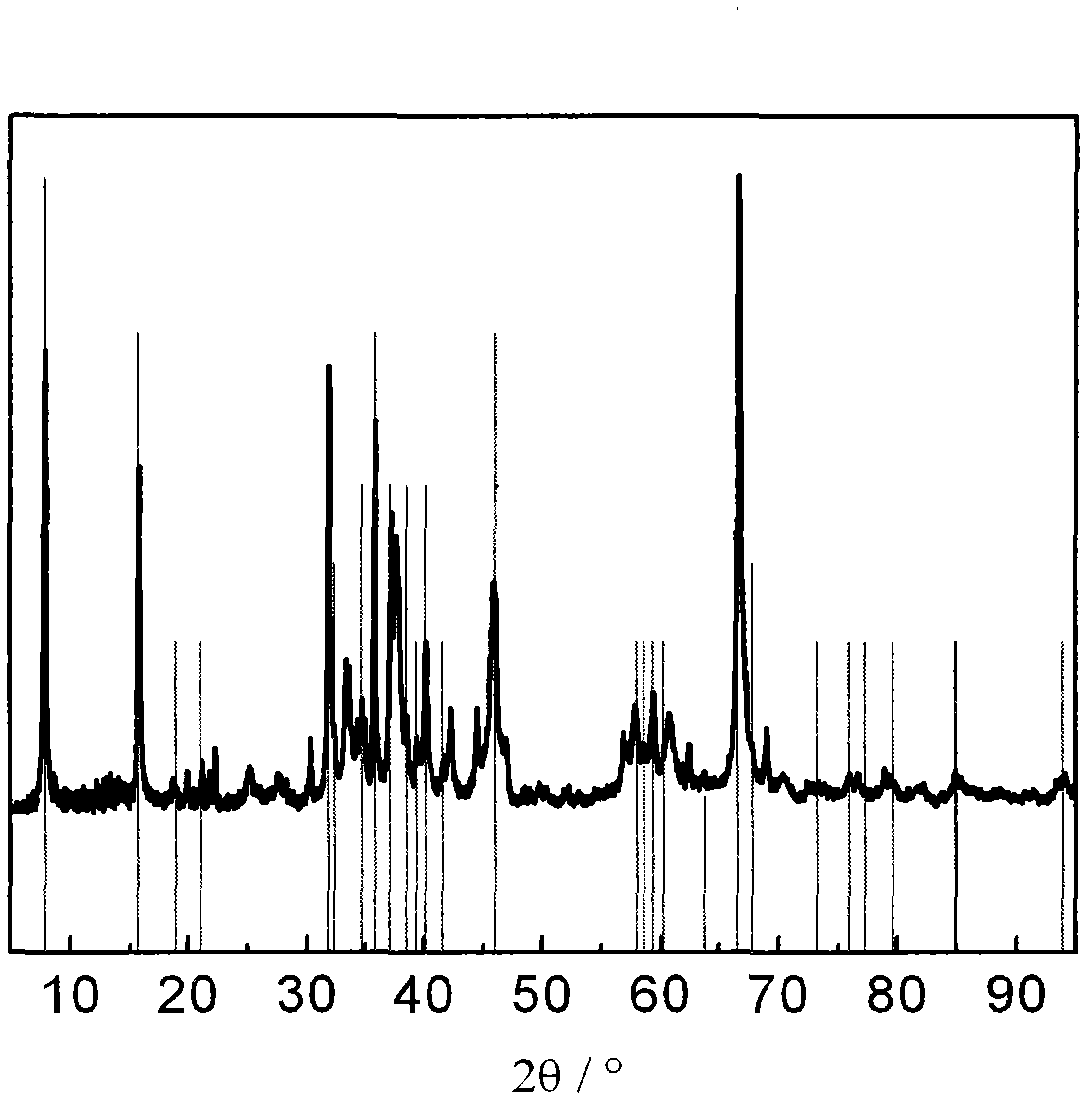

[0041] β”-Al with a thickness of 1 mm and modified by polyvinylidene fluoride membrane 2 o 3 The ceramic is fixed between the negative electrode chamber and the positive electrode chamber of the stainless steel electrolytic cell to keep the electrode chamber well sealed; a graphite rod is used as the anode and a nickel sheet is used as the cathode, which are respectively fixed in the positive and negative electrode chambers; 6 500ml of propylene carbonate organic electrolyte was injected into the negative electrode chamber, and argon gas was continuously fed into it for protection; an aqueous solution containing 1M NaCl was injected into the positive electrode chamber. Connect the positive and negative wires to the circuit, adjust the voltage to 3.6V, and after 12 hours of electrolytic reaction, discharge the aqueous solution in the positive chamber, recover the organic electrolyte in the negative chamber in a glove box filled with argon gas, and obtain metal deposits. Sodium...

Embodiment 2

[0043] Na-β-Al with a thickness of 2 mm 2 o 3 The diaphragm is fixed between the negative electrode chamber and the positive electrode chamber of the polytetrafluoroethylene electrolytic cell; graphite rods are used as anodes and nickel sheets are used as cathodes respectively; 500ml of acetonitrile solution containing 1M sodium perchlorate is injected into the negative electrode chamber, and argon gas is introduced For protection; inject 500mL of concentrated seawater into the cathode chamber. The voltage was adjusted to 4.0V, and after 24 hours of electrolysis, high-purity metal sodium was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com