Sterile bovine colostrum whey with natural immunocompetence and preparation method and application thereof

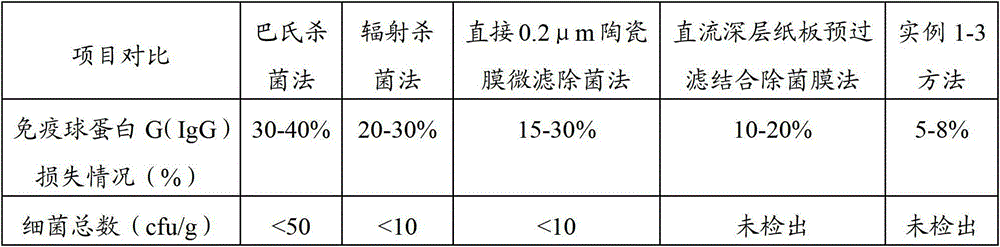

A technology of natural immunity and colostrum, applied in whey, application, dairy products, etc., can solve the problems of immunoglobulin retention, product irritating odor, whey membrane flux attenuation, etc., and achieve high immunoglobulin content , maintain natural activity, slow flux decay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

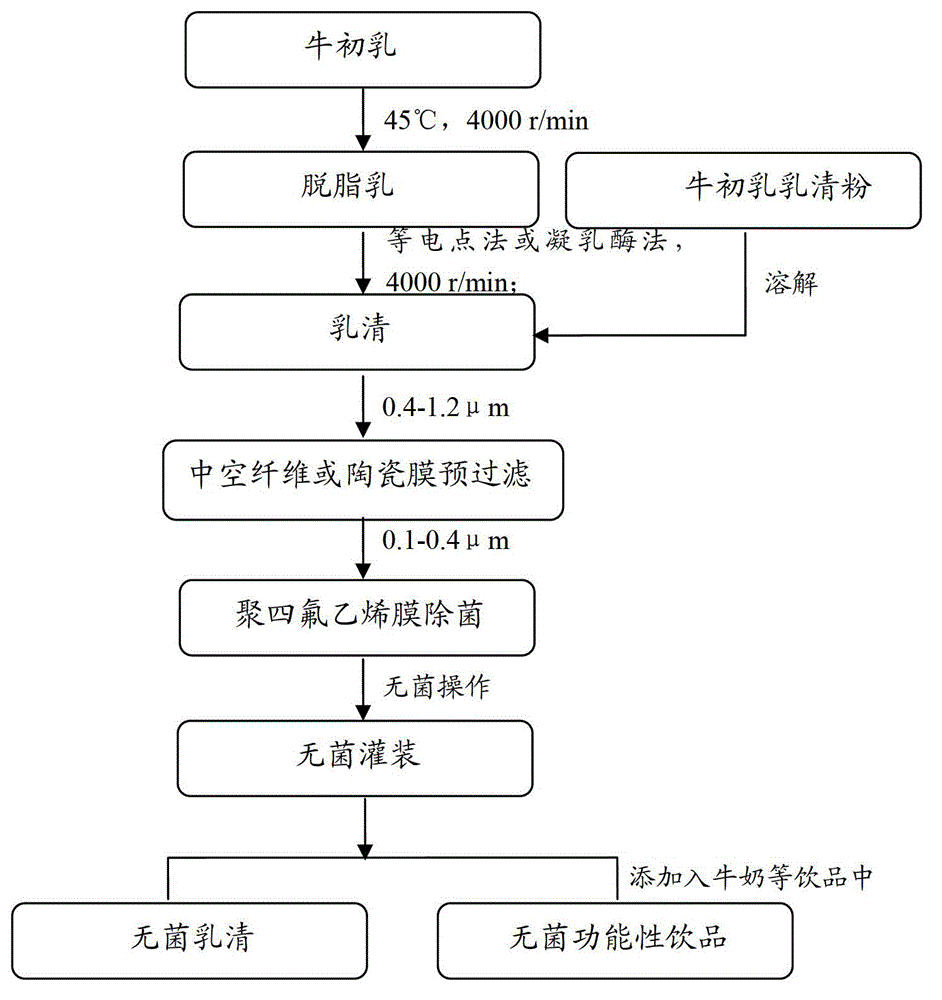

Method used

Image

Examples

Embodiment 1

[0023] Place 6L of bovine colostrum in a preparative centrifuge at 45°C and centrifuge at 4000r / min for 20min to remove fat to obtain 5L of defatted bovine colostrum. Use the rennet method to precipitate the casein in the skim colostrum, that is, heat the skim colostrum to 40°C, add rennet in the proportion of 0.02% of the weight of the skim milk, stir evenly, and let the casein coagulate. The coagulated casein is cut into 1-2cm blocks, the whey crude extract is filtered out, and centrifuged at 4000r / min for 20min to obtain the whey liquid. A 0.4μm hollow fiber membrane is used for pre-filtration to remove impurities such as fat, casein, and most bacteria in the whey, so that the active ingredients can penetrate and obtain a clear whey liquid. The inlet pressure is 1.0bar and the outlet pressure is 0.1 bar, temperature 20°C. Filter and sterilize through a 0.1 μm polytetrafluoroethylene membrane filter. Filled under aseptic conditions, it becomes aseptic bovine colostrum whey...

Embodiment 2

[0025] Place 6L of bovine colostrum in a preparative centrifuge at 45°C and centrifuge at 4000r / min for 20min to remove fat to obtain 5L of defatted bovine colostrum. Precipitate casein in defatted bovine colostrum by isoelectric point method, that is, adjust the pH of defatted bovine colostrum to 4.3 with 1M lactic acid, and let it stand at 40°C for 20 minutes. After casein precipitation is complete, centrifuge to obtain whey liquid. A 1.2μm hollow fiber membrane is used for pre-filtration to remove impurities such as fat, casein, and most bacteria in the whey, so that the active ingredients can penetrate and obtain a clear whey liquid. The inlet pressure is 1.0bar and the outlet pressure is 0.1 bar, temperature 20°C. Filter and sterilize through a 0.4 μm polytetrafluoroethylene membrane filter. Filled under aseptic conditions, it becomes aseptic bovine colostrum whey liquid. The whey liquid is added to milk to obtain a drink with the function of enhancing immunity, wherein...

Embodiment 3

[0027] Dissolve bovine colostrum whey powder with purified water at 30°C at a concentration of 7%, and stir for 30 minutes to obtain whey liquid. 1.0μm ceramic membrane is used for pre-filtration, the inlet pressure is 0.8bar, and the outlet pressure is 0.4bar. Filter and sterilize through a 0.3 μm polytetrafluoroethylene membrane filter. Filled under aseptic conditions, it becomes aseptic bovine colostrum whey liquid. The whey liquid is added to the fruit juice to obtain a drink with the function of enhancing immunity, wherein the added mass fraction of the whey liquid is 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com