High-dilution-rate and environment-friendly release agent for aluminum alloy

An environment-friendly, aluminum alloy technology, which is applied in the direction of casting molds, cores, and casting mold components, can solve the problem of toxic and harmful chemical raw materials that endanger environmental safety and human health, affect economic benefits, and keep high production costs for customers, etc. problem, to achieve the effect of excellent heat resistance, good adsorption, and excellent adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

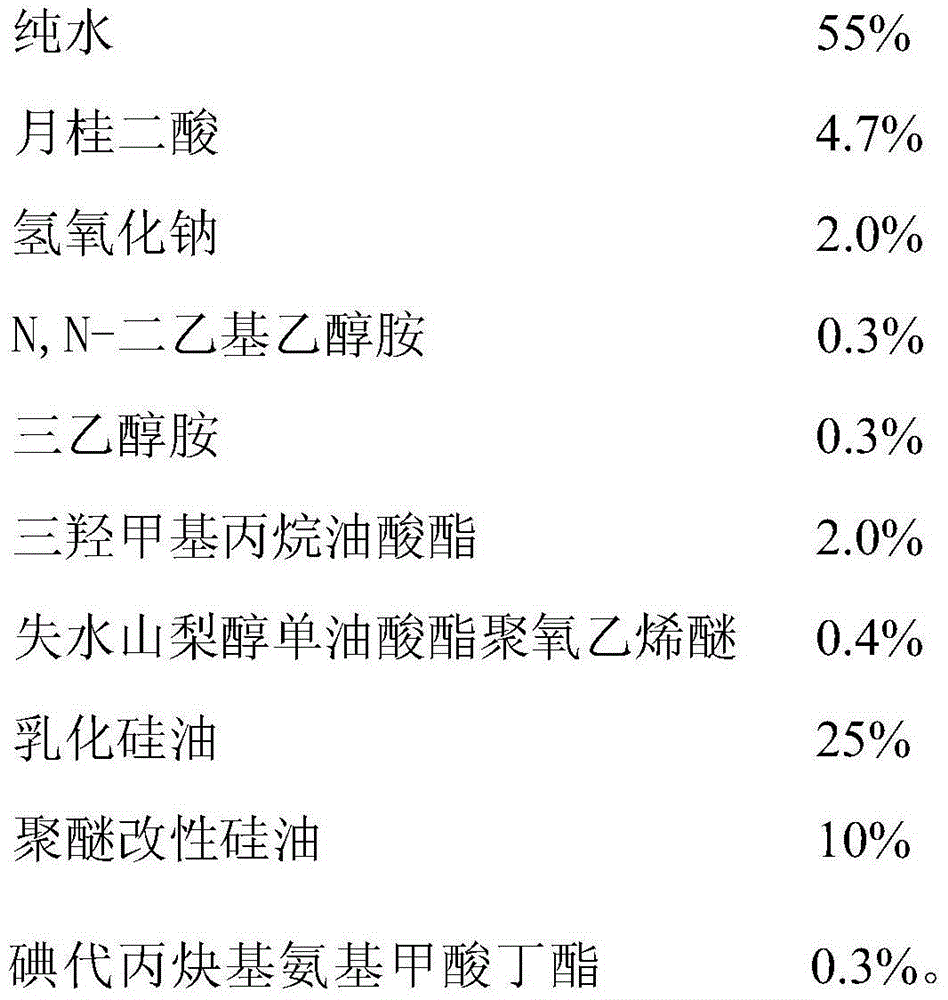

[0028] Mix and stir the components in the following percentages by weight to obtain the product:

[0029] Pure water 55%

[0030] Lauric acid 4.7%

[0032] N,N-Diethylethanolamine 0.3%

[0033] Triethanolamine 0.3%

[0034] Trimethylolpropane Oleate 2.0%

[0035] Sorbitan Monooleate Polyoxyethylene Ether 0.4%

[0036] Emulsified silicone oil 25%

[0037] Polyether modified silicone oil 10%

[0038] Butyl Iodopropynylcarbamate 0.3%.

Embodiment 2

[0040] Mix and stir the components in the following percentages by weight to obtain the product:

[0041] Synthetic lubricant 0~5% (eg 0%, 3%, 5%)

[0042] Organic acid 2-5% (eg 2%, 3%, 5%)

[0043] Organic amine 0~5% (eg 0%, 3%, 5%)

[0044] Inorganic base 0~5% (eg 0%, 3%, 5%)

[0045] Surfactant 0~5% (eg 0%, 3%, 5%)

[0046] Corrosion inhibitor 0~5% (for example 0%, 3%, 5%)

[0047] Silicone oil 5-35% (eg 5%, 15%, 35%)

[0048] Pure water 35-80% (eg 35%, 50%, 80%).

[0049] The sum of the amounts of the above components is 100%.

[0050] The organic acid is one or more of lauric acid, isophthalic acid, sebacic acid, nonanoic acid, and trimellitic anhydride.

[0051] Organic amines are 1,2-dimethylpropylamine, triethanolamine, hexamethylenediamine, triisopropanolamine, N,N-diethylethanolamine, 2-amino-2-methyl-1-propanol, caprolactam, One or several kinds of tallow propylene diamine.

[0052] The surfactant is sorbitan monooleate polyoxyethylene ether, fatty alcohol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com