Crystalline-type waterproof paint for preventing cement leakage

A waterproof coating and crystalline technology, which is applied in the field of crystalline waterproof coatings to prevent cement leakage, and achieves the effects of low cost, simple construction process, and simple tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 A crystalline waterproof coating for preventing cement leakage, prepared from the following raw materials according to the weight ratio;

[0022] Ordinary Portland cement 52.5 55 kg

[0023] Granulated blast furnace powder 95# 20 kg

[0024] Penetrant fatty alcohol polyoxyethylene ether 1.5 kg

[0025] Expanding agent calcium hydroxide 0.5 kg

[0026] Silica fume 4 kg

[0027] Quartz sand 22 kg

[0028] Modified bentonite 3 kg

[0029] Modified sodium silicate 4 kg

[0030] Polyacrylic acid complexing agent 10 kg

[0031] Polyethylene glycol crystal precipitation agent 2 kg.

[0032] Proportioning step: 55 parts by weight of ordinary Portland cement, 20 parts by weight of granulated blast furnace powder, 1.5 parts by weight of penetrating agent, 0.5 parts by weight of expansion agent, 4 parts by weight of silica fume, 22 parts by weight of quartz sand, modified expanded 3 parts by weight of lubricant, 4 parts by weight of modified sodium silicate, 1...

Embodiment 2

[0035] Embodiment 2. A crystalline waterproof coating for preventing cement leakage, which is formulated according to the weight ratio of the following raw materials;

[0036] Ordinary Portland cement 52.5 60 kg

[0037] Granulated blast furnace powder 95# 20 kg

[0038] Penetrant fatty alcohol polyoxyethylene ether 1 kg

[0039] Expanding agent magnesium hydroxide 1 kg

[0040] Silica fume 3 kg

[0041] Quartz sand 22 kg

[0042] Modified bentonite 2 kg

[0043] Modified sodium silicate 4 kg

[0044] Complexing agent 7 kg

[0045] Crystal precipitation agent 2 kg.

[0046] Processing method is with embodiment 1

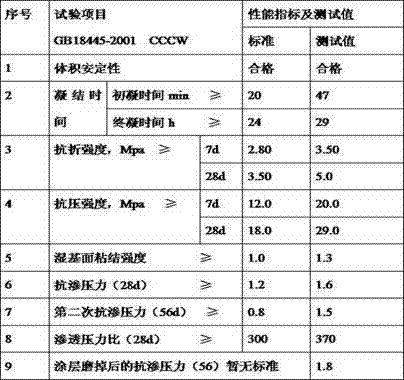

[0047] Table of physical properties of the osmotic crystalline waterproof coating described in Example 2 of the present invention

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com