Fluorocarbon paint for cabinet and preparation method

A coating and fluorocarbon technology, applied in anti-corrosion coatings, antifouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve problems that affect the long-term stable and reliable work of the cabinet, affect the normal performance of electronic appliances, and narrow the use space of the cabinet. and other problems, to achieve the effect of easy promotion, high cost performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The technological process and process parameters of the present embodiment are as follows:

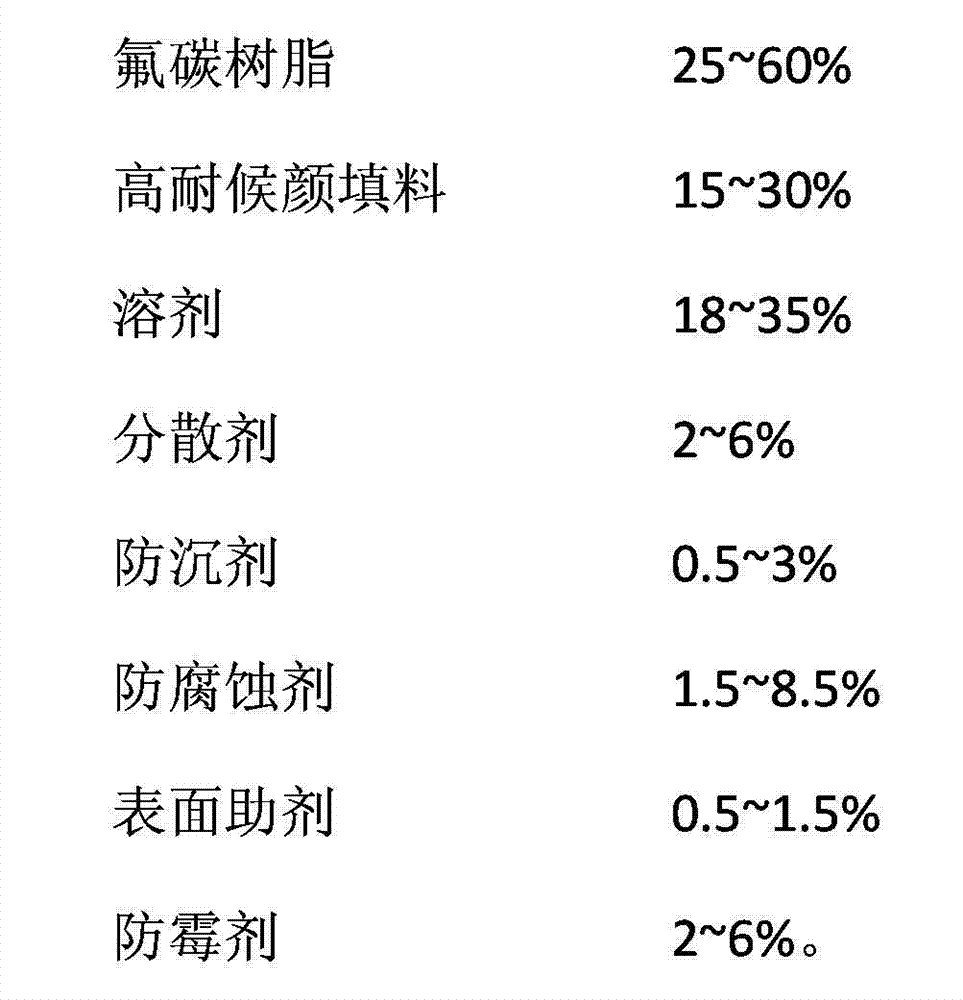

[0044] 1. The weight percentage of each component of component A is:

[0045]

[0046]

[0047] 2. Preparation of anti-sedimentation agent solution

[0048] The anti-settling agent is selected from organic bentonite, the solvent is selected from xylene, and the weight percentage ratio of organic bentonite to xylene is: organic bentonite: xylene = 15%: 85%. Mix them together at room temperature and then stir well.

[0049] 3. Preparation of anti-corrosion agent solution

[0050]The anti-corrosion agent is calcium sulfonate, the solvent is a mixed solvent of xylene and ethyl acetate, and the weight percentage ratio of the anti-corrosion agent to the solvent is: anti-corrosion agent:solvent=50%:50%. Mix them together at room temperature and then stir well.

[0051] 4. The preparation of component A of the main part of the paint is carried out at room temperature, and the ...

Embodiment 2

[0061] The technological process and process parameters of the present embodiment are as follows:

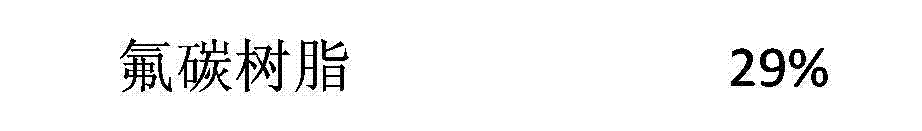

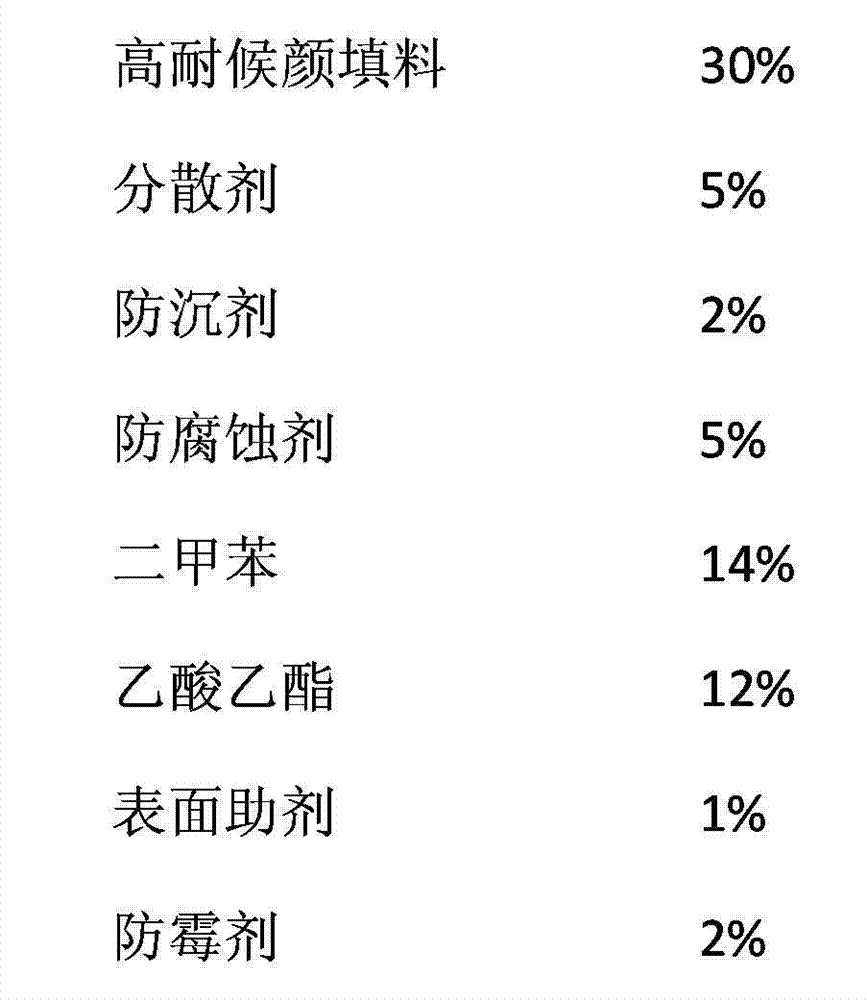

[0062] 1. The weight percentage of each component of component A is:

[0063]

[0064]

[0065] 2. Preparation of anti-sedimentation agent solution

[0066] The anti-settling agent is organic bentonite, and the solvent is a mixed solvent of xylene and butyl acetate. The ratio of organic bentonite to solvent is: organic bentonite:solvent=8%:92%. Mix them together at room temperature and then stir well.

[0067] 3. Preparation of anti-corrosion agent solution

[0068] The anticorrosion agent is calcium sulfonate, the solvent is a mixed solvent of xylene and butyl acetate, and the ratio of anticorrosion agent to solvent is: anticorrosion agent:solvent=65%:35%. Mix them together at room temperature and then stir well.

[0069] 4. The preparation of the main part of the paint is carried out at room temperature. The fluorocarbon resin with a fluorine content of 22% and a hyd...

Embodiment 3

[0079] The technological process and process parameters of the present embodiment are as follows:

[0080] 1. The weight percentage of each component of component A is:

[0081]

[0082]

[0083] 2. Preparation of anti-sedimentation agent solution

[0084] The anti-sedimentation agent is polyamide wax, and the solvent is a mixed solvent of xylene and butyl acetate. The weight ratio of polyamide wax to solvent is: polyamide wax:solvent=20%:80%. Mix them together at room temperature and then stir well.

[0085] 3. Preparation of anti-corrosion agent solution

[0086] Magnesium sulfonate is selected as the anticorrosion agent, a mixed solvent of xylene and butyl acetate is selected as the solvent, and the weight ratio of the anticorrosion agent to the solvent is: anticorrosion agent:solvent=52%:48%. Mix them together at room temperature and then stir well.

[0087] 4. The main part of the paint is prepared at room temperature. The fluorocarbon resin with a fluorine cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com