Engineering bacteria producing DL-alanine and method of producing DL-alanine by using engineering bacteria

A technology of engineering bacteria and alanine, applied in the field of DL-alanine production, can solve problems such as being difficult to realize industrialized production, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

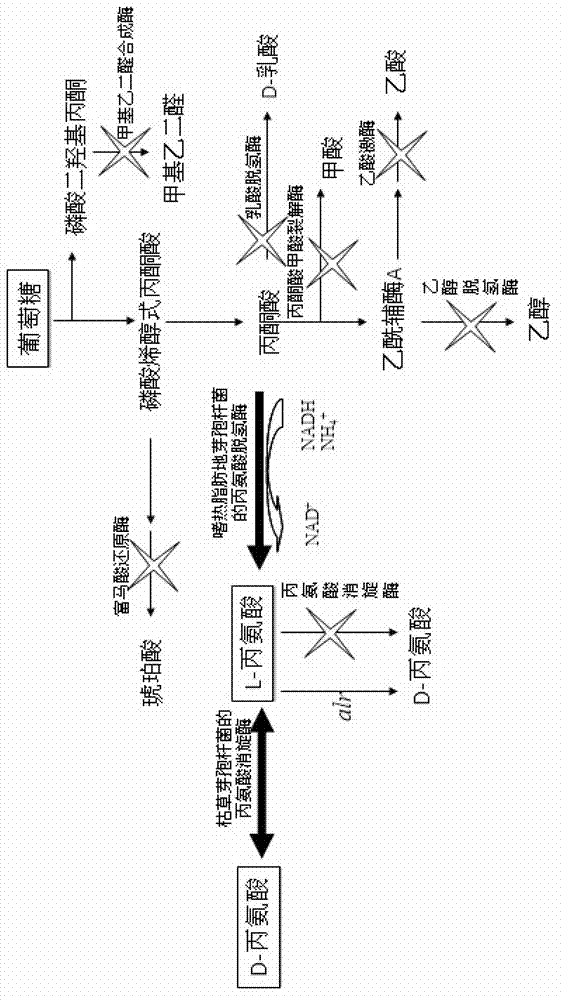

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1X

[0032] Construction of embodiment 1XZ-A30 bacterial strain

[0033] The construction of the XZ-A30 strain includes two steps (a) and (b), the specific operations are as follows:

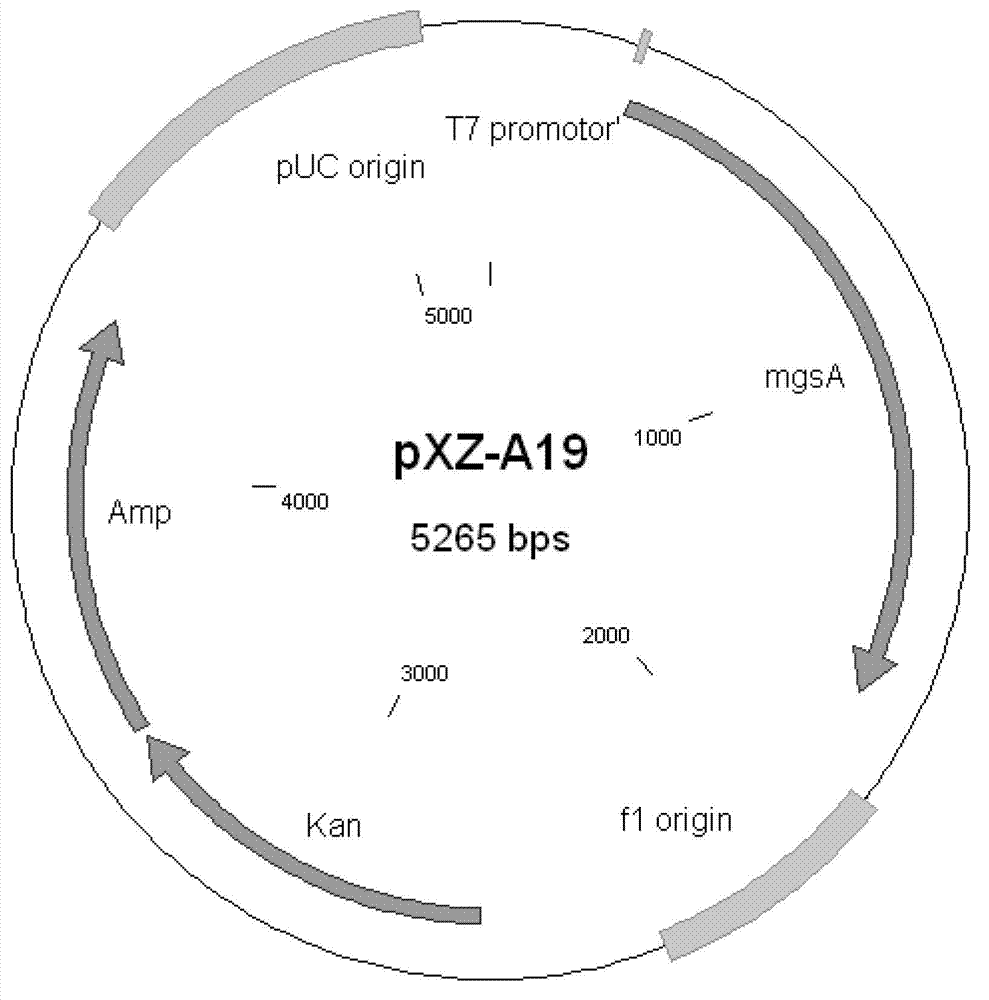

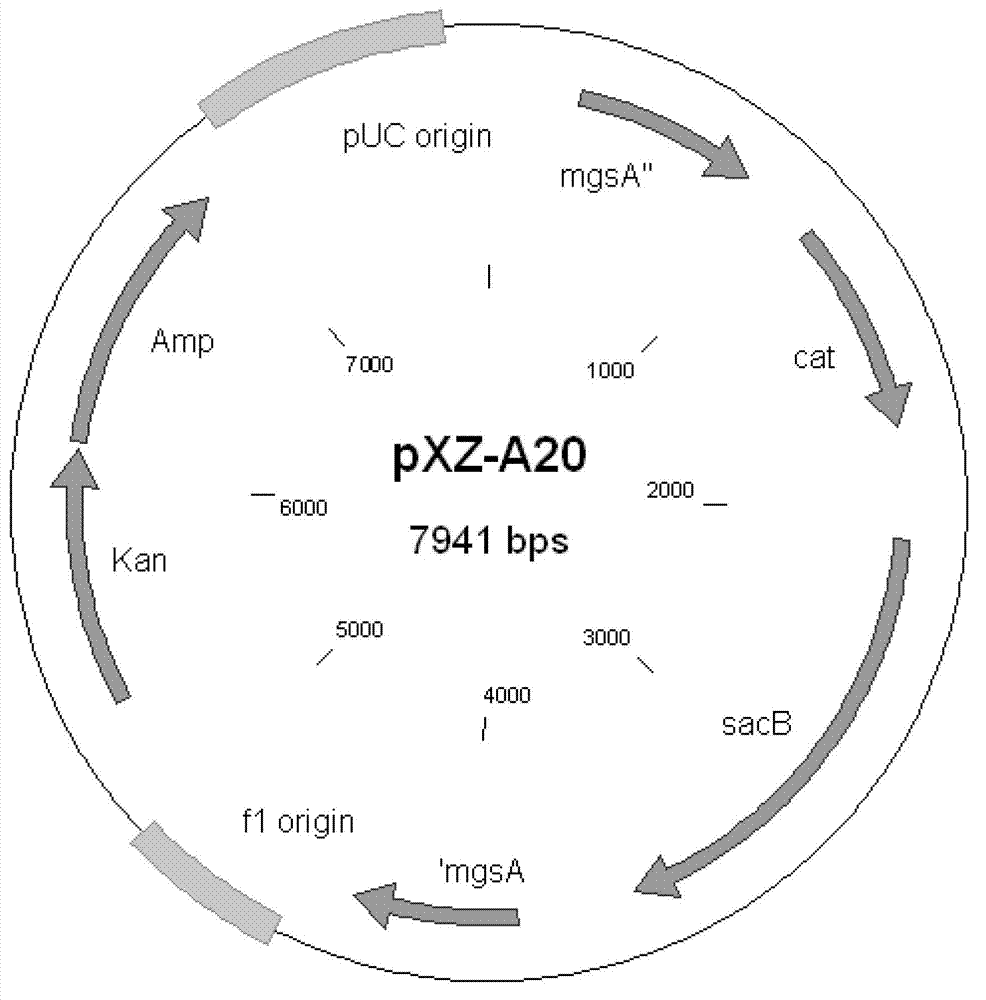

[0034] (a) Cloning and integration of alanine racemase gene

[0035] The cloning and integration of alanine racemase gene alaR are divided into the following two steps:

[0036] (a1) Cloning of alaR gene

[0037] Take Bacillus subtilis 168 (Moszer I, Jones LM, Moreira S, Fabry C, Danchin A. SubtiList: the reference database for the Bacillus subtilis genome. Nucleic Acids Res. 2002, 30 (1): 62-65. Publicly available from Anhui Huaheng Bioengineering Co., Ltd.) genomic DNA was used as a template, and primers alaR up-XbaI / alaR down-SalI were used to amplify the alanine racemase gene alaR (SEQ ID NO: 14) of Bacillus subtilis. The primer sequences are:

[0038] alaR up-XbaI: GGAGAGTCTAGAATGAGCACAAAACCTTT (SEQ ID NO: 1);

[0039] alaR down-SalI: CGCTGCGTCGACTTAATTGCTTATATTTACC (SEQ ID NO: 2).

[0040...

Embodiment 2

[0079] Embodiment 2 produces DL-alanine with XZ-A30 bacterial strain anaerobic fermentation

[0080] Both the seed medium and the fermentation medium consist of: glucose 120g / L, ammonium chloride 4g / L, NaH 2 PO 4 5g / L, Na 2 HPO 4 5g / L, MgSO 4 ·7H 2 O1g / L, CaCl 2 2H 2 O 0.1g / L, trace inorganic salt 4ml / L, medium pH 6.5. The composition of trace inorganic salts is: FeCl 3 ·6H 2 O 1.5 mg, CoCl 2 ·6H 2 O 0.1 mg, CuCl 2 2H 2 O 0.1mg, ZnCl 2 0.1 mg, Na 2 MoO 4 2H 2 O 0.1 mg, MnCl 2 4H 2 o 2 0.2mg, dilute to 1L with distilled water, and filter to sterilize.

[0081] 150ml of seed culture medium in a 250ml Erlenmeyer flask, sterilized at 121°C for 15min. After cooling, insert XZ-A30, culture temperature is 30°C, shaker speed is 50r / min (50 revolutions / min), culture for 18h, used for fermentation medium inoculation.

[0082] The volume of the fermentation medium in a 3L fermenter is 2.4L, and it is sterilized at 121°C for 15min. The inoculum size is 0.1% (V / V,), ...

Embodiment 3

[0085] Embodiment 3 produces DL-alanine with XZ-A30 bacterial strain anaerobic fermentation

[0086] Both the seed medium and the fermentation medium consist of: glucose 120g / L, ammonium chloride 4g / L, NaH 2 PO 4 5g / L, Na 2 HPO 4 5g / L, MgSO 4 ·7H 2 O1g / L, CaCl 2 2H 2 O 0.1g / L, trace inorganic salt 4ml / L, medium pH 6.5. The composition of trace inorganic salts is: FeCl 3 ·6H 2 O 1.5 mg, CoCl 2 ·6H 2 O 0.1 mg, CuCl 2 2H 2 O 0.1mg, ZnCl 2 0.1 mg, Na 2 MoO 4 2H 2 O 0.1 mg, MnCl 2 4H 2 o 2 0.2mg, dilute to 1L with distilled water, and filter to sterilize.

[0087] 150ml of seed culture medium in a 250ml Erlenmeyer flask, sterilized at 121°C for 15min. After cooling, insert XZ-A30, culture temperature is 30°C, shaker speed is 50r / min (50 revolutions / min), culture for 18h, used for fermentation medium inoculation.

[0088] The volume of the fermentation medium in a 3L fermenter is 2.4L, and it is sterilized at 121°C for 15min. The inoculum size is 0.1% (V / V,), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com