Polyurethane/polyacrylate copolymer and BOPP (Biaxially-oriented Polypropylene) film prepared by same

A technology of polyacrylate and hydroxyacrylate, which is applied in the direction of coating, etc., can solve the problems of insufficient performance of the coating film, poor coating performance, short service life, etc., and achieve simple and rapid film forming process and good dimensional stability , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

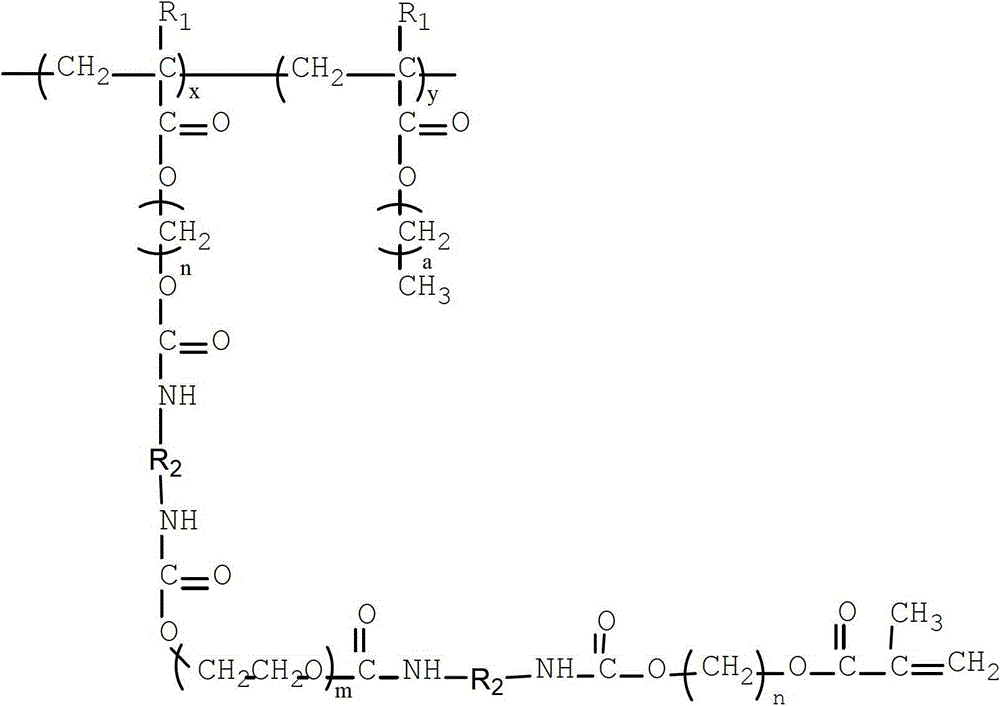

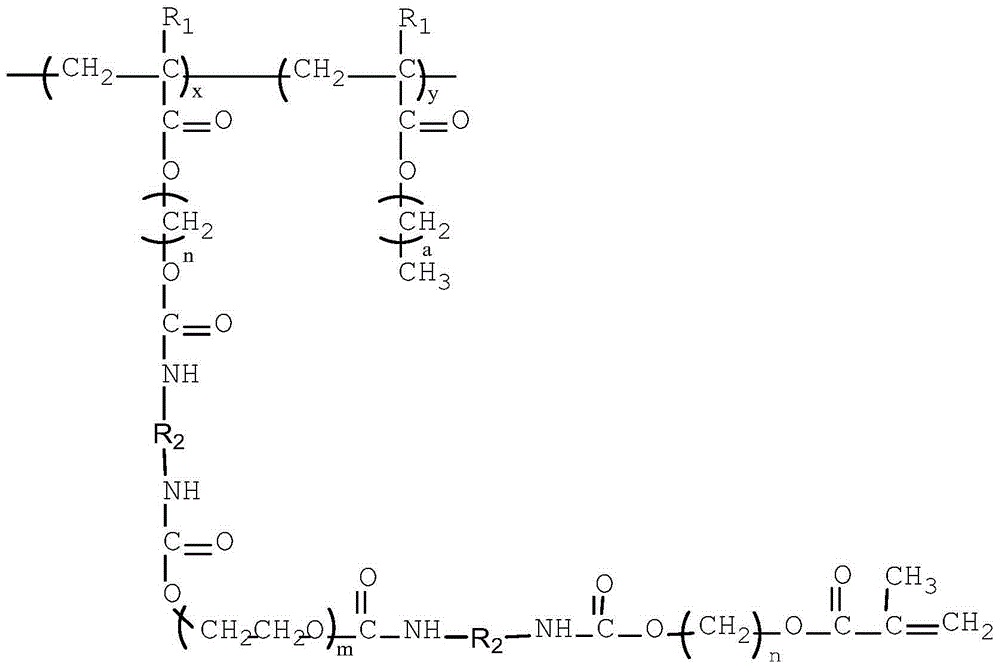

Image

Examples

Embodiment 1

[0030] (1) Preparation of polyurethane macromonomer terminated with hydroxyethyl methacrylate: dehydrate polyether diol by rotary evaporation, and vacuum dry it in a vacuum oven at 120°C to obtain dehydrated polyether diol . According to the weight ratio, add 100 parts of dehydrated polyether diol N210 (molecular weight: 1000) into a reactor equipped with a stirrer and a thermometer, raise the temperature to 80°C, and then add 34 parts of toluene diisocyanate, under the condition of stirring Mix evenly at 80°C and continue to react for 3 hours to obtain a polyurethane prepolymer with an end group of -NCO-; then add 26 parts of hydroxyethyl methacrylate to block the -NCO-, and react at 80°C for 4 Hours later, the sample was taken for testing, and the results of its infrared spectrum showed that at 3335cm -1 The -NH- stretching vibration peak appeared at 1730cm -1 The carbonyl stretching vibration peak appeared at , indicating that the isocyanate group of toluene diisocyanate ...

Embodiment 2

[0036] (1) Preparation of polyurethane macromonomer terminated with hydroxyethyl methacrylate: dehydrate polyether diol by rotary evaporation, and vacuum dry it in a vacuum oven at 120°C to obtain dehydrated polyether diol . According to the weight ratio, add 100 parts of dehydrated polyether diol N210 (molecular weight: 1000) into a reactor equipped with a stirrer and a thermometer, raise the temperature to 70°C, and then add 50 parts of diphenylmethane diisocyanate, Mix well under the condition of stirring, and continue to react for 3 hours to obtain a polyurethane prepolymer whose terminal group is -NCO-; then add 26 parts of hydroxyethyl methacrylate to block -NCO-, and react at 80°C After 4 hours, the sample was taken for testing, and the results of its infrared spectrum showed that at 3335cm -1 The -NH- stretching vibration peak appeared at 1730cm -1 The carbonyl stretching vibration peak appeared at , indicating that the isocyanate group of diphenylmethane diisocyanat...

Embodiment 3

[0042] (1) Preparation of polyurethane macromonomer terminated with hydroxyethyl methacrylate: dehydrate polyether diol by rotary evaporation, and vacuum dry it in a vacuum oven at 120°C to obtain dehydrated polyether diol . According to the weight ratio, add 100 parts of dehydrated polyether diol N210 (molecular weight: 1000) into a reactor equipped with a stirrer and a thermometer, raise the temperature to 85 ° C, and then add 44 parts of isophorone diisocyanate, in Mix well under stirring conditions, and continue to react for 7 hours to obtain a polyurethane polymer whose end group is -NCO-; then add 26 parts of hydroxyethyl methacrylate to end-cap the -NCO-, and react at 80°C for 3 Hours later, the sample was taken for testing, and the results of its infrared spectrum showed that at 3335cm -1 The -NH- stretching vibration peak appeared at 1730cm -1 The carbonyl stretching vibration peak appeared at , indicating that the isocyanate group of isophorone diisocyanate reacted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com