Method for improving interlayer toughness of fiber reinforced resin matrix composites

A fiber-reinforced resin and composite material layer technology, which is applied in the field of fiber-reinforced resin-based composite material preparation, can solve problems such as unfavorable process, increased difficulty of process realization, increased viscosity of resin system, etc., and achieves improved comprehensive mechanical properties, interlayer Effects of increased shear strength and interlaminar fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

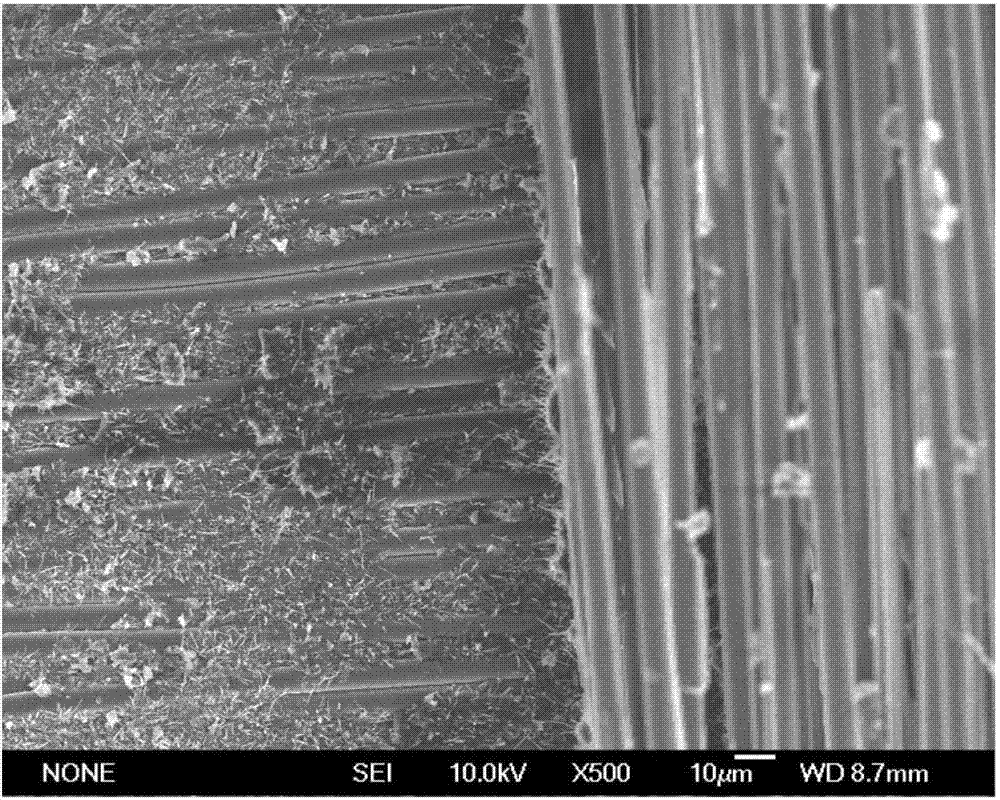

[0021] Example 1: Preparation of carbon nanotube / carbon fiber unidirectional fabric reinforced epoxy resin-based composite material

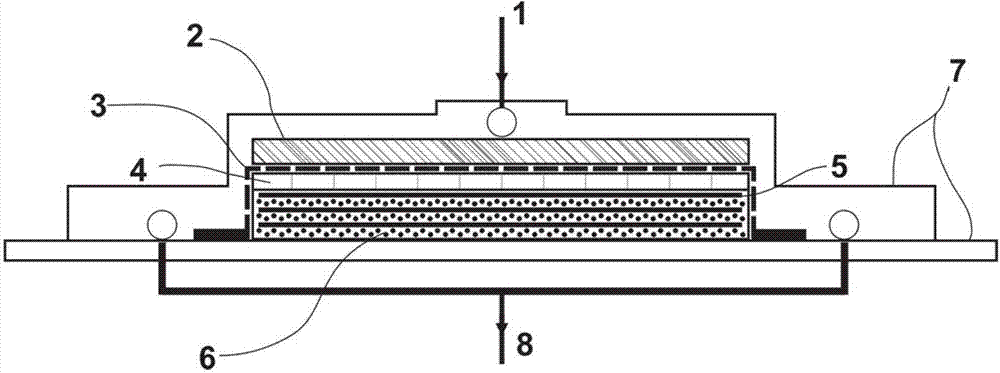

[0022] Put 1g of carbon nanotubes, 100ml of acetone, and 200g of epoxy bisphenol A resin in a beaker, and then use the JY92-IIDN ultrasonic continuous flow cell disruptor of Ningbo Xinzhi Biotechnology Co., Ltd. to perform ultrasonic dispersion treatment on it, with a power of 900 watts, stop stirring and ultrasonic after 1 hour, put the mixed solution on a rotary evaporator, remove acetone under reduced pressure, and the acetone obtained can be recycled. The polyamine curing agent is added according to the stoichiometric ratio, and the resin solution containing carbon nanotubes is evenly coated on the single-layer fiber fabric to ensure uniform coating. Then lay the carbon fiber unidirectional fabric into the mold cavity according to the number of layers and structure of the product design, to ensure that it fits tightly with each position of t...

Embodiment 2

[0024] Example 2: After the carbon nanotube / carbon fiber unidirectional fabric preform prepared in Example 1 is sealed and coated with a polytetrafluoroethylene filter membrane with a pore size of 0.45 μm, the molds are closed, and the vacuum-assisted resin transfer molding method is adopted The mold was filled and infiltrated with epoxy bisphenol A resin and polyamine curing agent system at 40°C, and finally cured at 120°C for 1 hour and 180°C for 2 hours. The resin content can be controlled between 20% and 50%, the interlaminar shear strength ILSS of the composite material can be increased by up to 36%, and the type II interlaminar fracture toughness G IIC The maximum increase is 65%.

Embodiment 3

[0025] Embodiment 3: preparation nano-SiO2 / glass fiber square cloth reinforced vinyl resin matrix composite material

[0026] Mix 5g of nano-SiO2 with 200g of vinyl resin and methyl ethyl ketone peroxide curing agent through a homogeneous mixer (Germany IKA-T65D), and evenly coat it on a single-layer glass fiber grid cloth, and then according to the number of layers designed for the product Prepare the preform with the structure to ensure that the preform is closely attached to each position of the cavity to prevent the layup from twisting and wrinkling. Then, a layer of cellulose filter membrane with a pore size of 0.025 μm is coated on the surface of the preform, which can be sealed and mold-closed with adhesive tape.

[0027] The reinforced fabric was then infiltrated a second time with a low-viscosity vinyl resin and methyl ethyl ketone peroxide curing agent system at room temperature by vacuum-assisted liquid transfer molding, and finally cured at 50°C for 3 hours. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com