Flame-retardant reflection insulation paint and preparation method thereof

A reflective heat-insulating coating and flame-retardant technology, applied in the field of architectural coatings, can solve the problems of poor flame retardancy and low storage stability of coatings, and achieve the effects of avoiding compatibility problems, good dispersibility, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

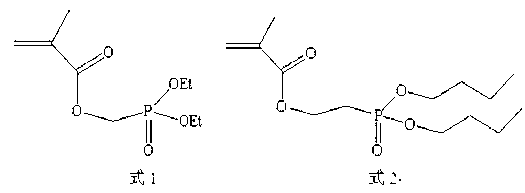

[0046] (1) Add 3 parts by weight of emulsifier (the mass ratio of SDBS and OP-10 is 2:1), and 20 parts by weight of deionized water into a three-necked bottle, and pre-emulsify for 15 minutes. Then, 7 parts by weight of the first acrylic monomer (diethoxy phosphate methyl methacrylate, formula 1) and 45 parts by weight of the second acrylic monomer (butyl methacrylate 20 parts by weight, 5 parts by weight of methyl methacrylate, 2 parts by weight of acrylic acid, 15 parts by weight of butyl acrylate, 3 parts by weight of 2-ethylhexyl acrylate), 0.4 parts by weight of initiator KPS, 3 parts by weight of buffer NaHCO 3 and 20 parts by weight of deionized water. After the dropwise addition, stir at high speed for 1 h to obtain a monomer pre-emulsion, which is set aside. Take 1 / 3 of the monomer pre-emulsion and add it into a four-neck flask equipped with a reflux condenser, a stirrer and a constant pressure dropping funnel, and stir to raise the temperature to 82°C. When the sys...

Embodiment 2

[0049] (1) Add 3 parts by weight of emulsifier (the mass ratio of SDBS and OP-10 is 2:1), and 20 parts by weight of deionized water into a three-necked bottle, and pre-emulsify for 20 minutes. Then, 10 parts by weight of the first acrylic monomer (diethoxy phosphate methyl methacrylate, formula 1) and 42 parts by weight of the second acrylic monomer (butyl methacrylate 20 Parts by weight, 2 parts by weight of methyl methacrylate, 2 parts by weight of acrylic acid, 15 parts by weight of butyl acrylate, 3 parts by weight of 2-ethylhexyl acrylate), 0.4 parts by weight of initiator KPS, 3 parts by weight of buffer NaHCO 3 and 20 parts by weight of deionized water. After the dropwise addition, stir at high speed for 1 h to obtain a monomer pre-emulsion, which is set aside. Take 1 / 3 of the monomer pre-emulsion and add it into a four-neck flask equipped with a reflux condenser, a stirrer and a constant pressure dropping funnel, and stir to raise the temperature to 82°C. When the sy...

Embodiment 3

[0052] (1) The same steps as in Example 1 were used to prepare the acrylic emulsion S1 containing phosphate groups.

[0053] (2) Add 48 parts by weight of deionized water, 0.4 parts by weight of preservative, 2 parts by weight of wetting and dispersing agent, 1.6 parts by weight of defoaming agent, and 3 parts by weight of anti-mold and fungicide into the dispersion tank, at a speed of 500rpm / min Stir at a uniform speed; continue stirring and add 60 parts by weight of titanium dioxide, 20 parts by weight of sericite and 20 parts by weight of reflective heat insulation powder, and stir for 50 minutes at a speed of 1500 rpm / min; then add 180 parts by weight of Acrylic emulsion S1 containing phosphate groups, 0.8 parts by weight of defoamer, 15.4 parts by weight of film-forming agent and 8 parts by weight of antifreeze, stirred for 10 minutes, and then added 40 parts by weight of hollow glass microspheres (each heating capacity half of the previous time), stirred for 1 hour; fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com