Organic solar battery and manufacturing method thereof

A solar cell and manufacturing method technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as randomness and uncontrollability, light leakage, and inability to fully absorb scattered light, achieve high production application value, ensure high fidelity, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example )

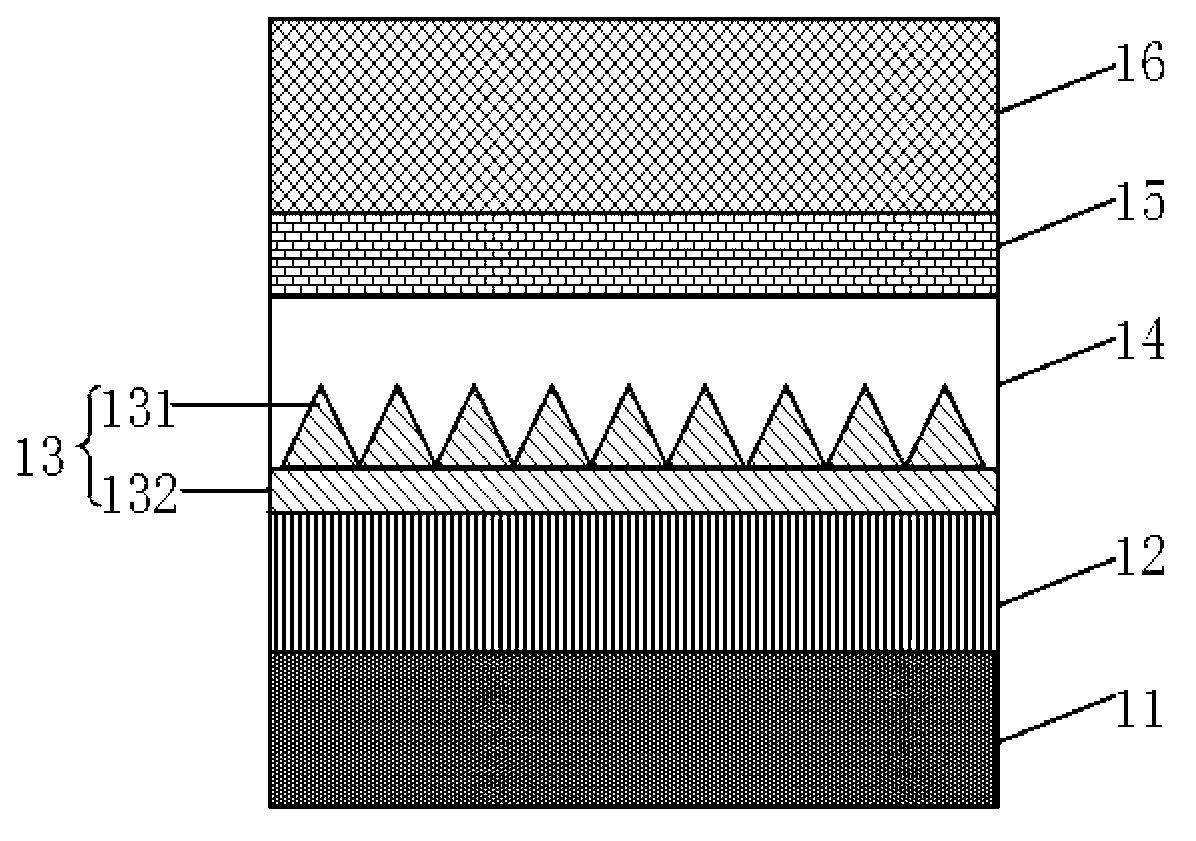

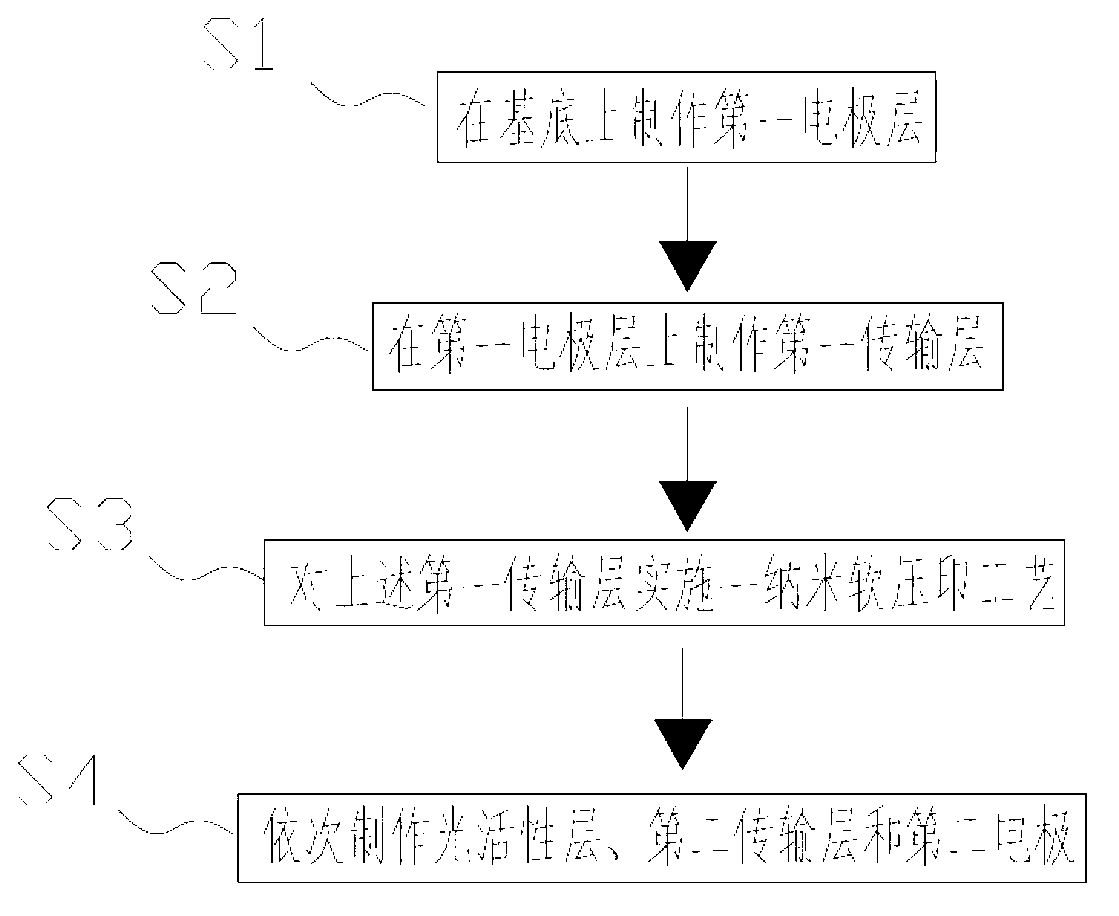

[0082] See Figure 5 , Figure 6 , Figure 5 is a schematic diagram of the method for fabricating an organic solar cell in the first embodiment, Figure 6is the surface pattern on the imprint template in the first embodiment.

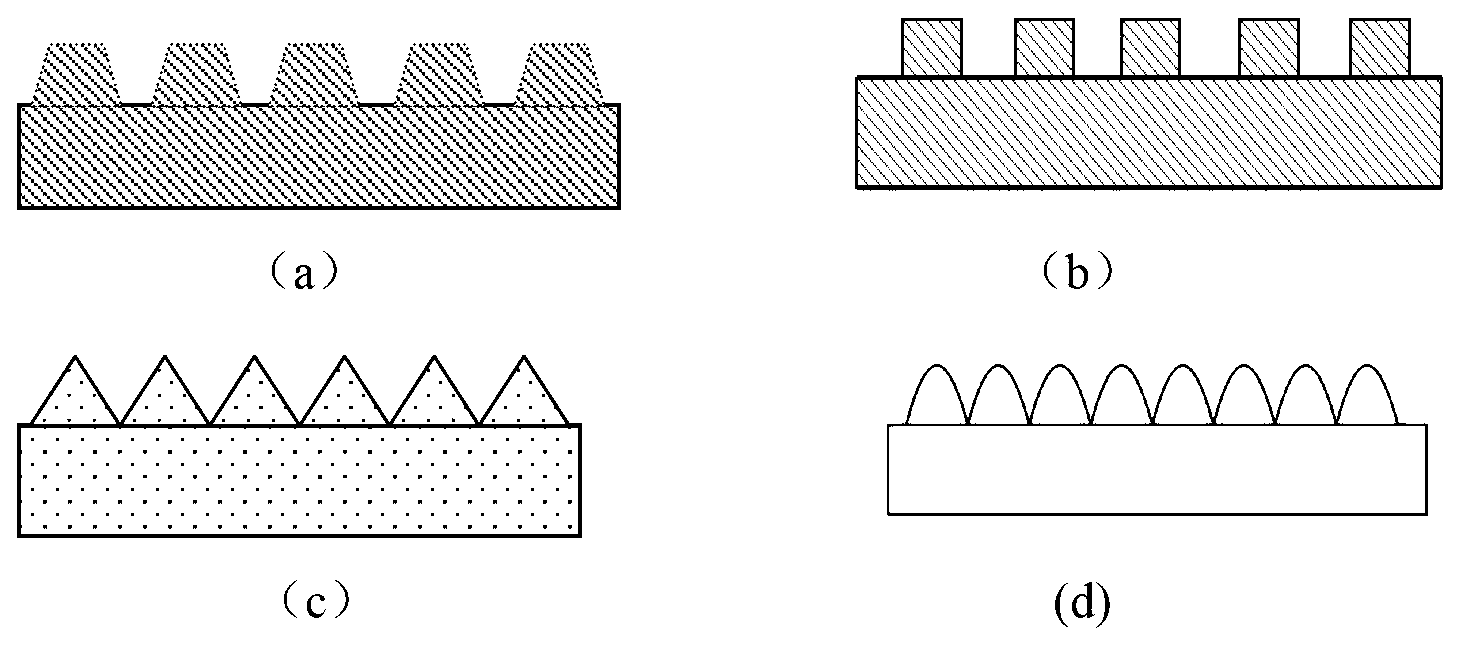

[0083] First, the two-dimensional lattice nano-concave-convex structure template 21 is produced by laser interference method, and the heat-sensitive imprinting material PDMS is used to transfer the two-dimensional lattice on the template to PDMS, and heat and solidify while applying pressure to form grooves with a depth of 50nm. A two-dimensional dot matrix embossing core 22 with a period of 200 nm.

[0084] The mold is released, and the nanostructure 21 on the template is copied to the core 22 of the imprinting mold.

[0085] Then, using ordinary float glass as the substrate, indium tin oxide (ITO) is evaporated on the substrate as the first electrode (not shown in the figure), and zinc oxide (ZnO) is spin-coated by the traditional sol-gel method. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com