A kind of calcium magnesium mud treatment and nitric water recovery method

A recovery method, calcium magnesium mud technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage multi-stage treatment, etc., can solve difficult maintenance, easy blockage of filter frame feeding port, nitric acid Large amount of water waste and other problems can be achieved to reduce investment costs and maintenance costs, solve the blockage of sewage pumps, and save floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following non-limiting examples illustrate the invention.

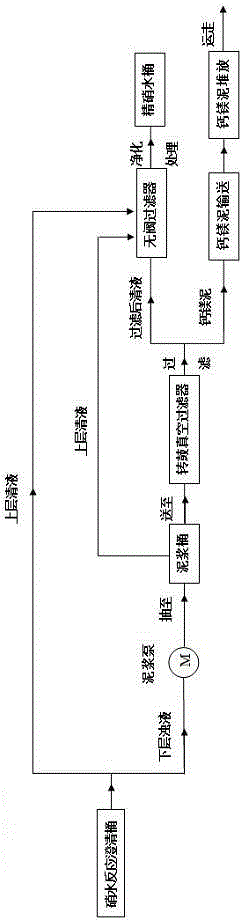

[0013] Such as figure 1 Shown, a kind of calcium magnesium mud treatment and nitric water recovery method, comprise the following steps:

[0014] 1) The supernatant liquid after the nitric water reaction clarification is filtered through a valveless filter, and then the nitric water is recovered;

[0015] 2) After clarification of the lower turbid liquid after the nitric water reaction clarification, the supernatant liquid is filtered through the valveless filter to recover the nitric water, and the lower layer mud is filtered through the rotary drum vacuum filter, and the clear liquid produced is After the liquid is filtered through the valveless filter, the nitric water is recovered, and the calcium-magnesium mud produced enters the subsequent treatment.

[0016] A device for the aforementioned calcium magnesium mud treatment and nitrate recovery method, comprising a nitrate reaction clarification devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com