Method and device for collecting microalgae through continuous culture and in-situ self-flocculation

A technology of self-flocculation and microalgae, which is applied to the device for continuous cultivation and in-situ self-flocculation harvesting chlorella, cultivation and harvesting of microalgae, continuous cultivation and in-situ self-flocculation harvesting of chlorella, can solve the problem. Difficulty in separation, low algal cell density, and high production costs, to achieve the effects of reducing environmental pollution, simple equipment structure, and reduced processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

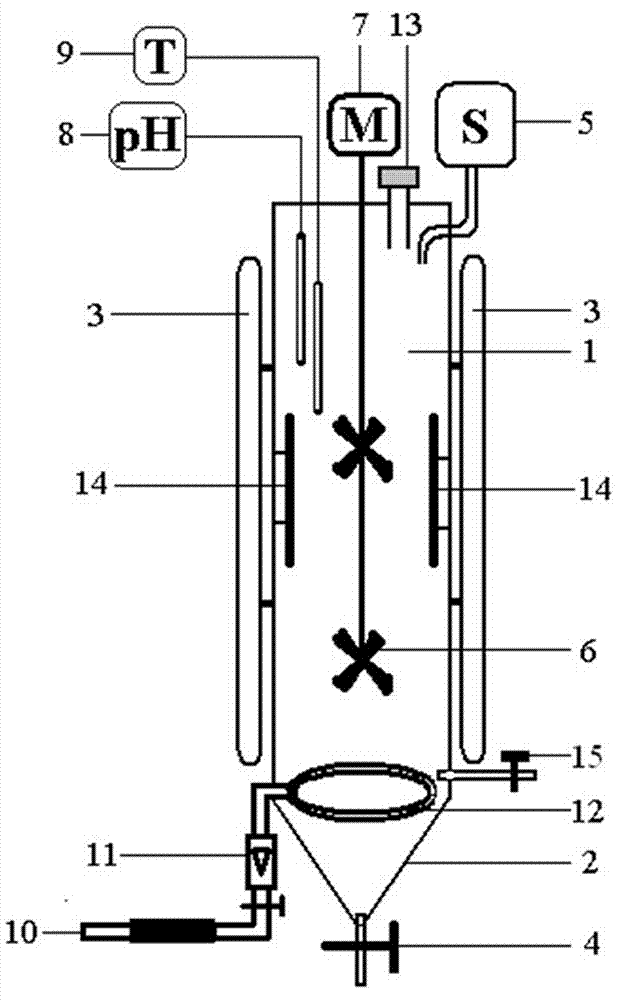

[0035] 1. Microalgae continuous culture and in-situ self-flocculation harvesting device

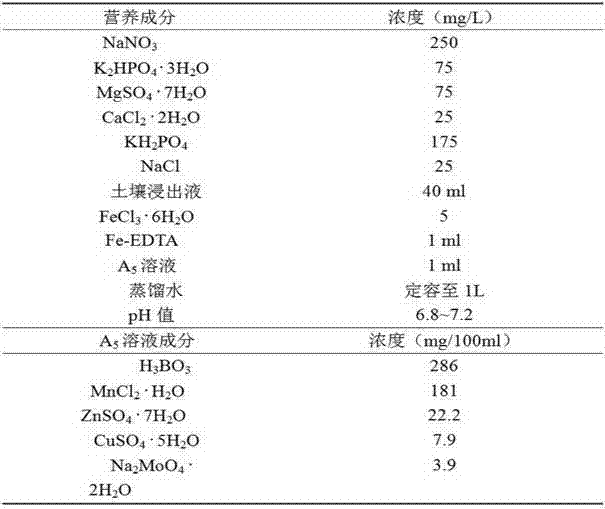

[0036] Microalgae continuous culture and in-situ self-flocculation harvesting device (refer to figure 1 ), including a column reactor 1 with an inverted cone 2 at the bottom (the height of the cone is 10-40 cm) (the material of the reactor is colorless and transparent organic glass; the column is cylindrical, and the inner diameter of the column is 10-40 cm , the height of the column shaft is 50~200 cm); and an algae discharge valve 4 is provided at the bottom of the inverted cone. The lower part of the column reactor 1 is provided with an aeration device, and a certain proportion of CO is introduced into the column. 2 of sterile air to achieve air supply and CO 2 biological fixation. The ventilation device includes a gas distributor 12 arranged in the column reactor 1 and a ventilation pipeline 10 installed outside the column reactor, a filter membrane or a filter element is arranged ...

Embodiment 2

[0050] 1. Microalgae continuous culture and in-situ self-flocculation harvesting device: the same as in Example 1.

[0051] 2. Microalgae continuous culture and in-situ self-flocculation harvesting process:

[0052] (1) Chlorella pyrenoidosa ( Chlorella pyrenoidosa ) Preparation of seeds: same as in Example 1;

[0053] (2) The configuration of wastewater medium: take some urban domestic wastewater, let it settle for pretreatment, take the supernatant and filter it with a 60-mesh filter, and then add nutrients (g / L) according to the following concentration: KNO 3 1.0 g / L, NaH 2 PO 4 0.2 g / L, NaHCO 3 0.5 g / L, MgSO 4 ·7H 2 O 0.1 g / L, CaCl 2 2H 2 O 50 mg / L, NaCl 200 mg / L, FeCl 3 . 6H 2 O 20 mg / L. Adjust the pH of the culture medium to 7.2; sterilize at 121°C, 0.1 MPa for 20 min, and then cool down for use.

[0054] (3) Inoculation and cultivation: inject the above medium into a sterilized column reactor, insert the wet heavy algae cell concentration at 400 mg / L,...

Embodiment 3

[0058] 1. Microalgae continuous culture and in-situ self-flocculation harvesting device: the same as in Example 1.

[0059] 2. Microalgae continuous culture and in-situ self-flocculation harvesting process:

[0060] (1) Chlorella pyrenoidosa ( Chlorella pyrenoidosa ) Preparation of seeds: same as in Example 1;

[0061] (2) Configuration of wastewater medium: Take wastewater from a certain farm, let it settle for pretreatment, take the supernatant and filter it with a 60-mesh filter, add tap water to dilute it by 1:1 volume, and then add nutrients at the following concentration ( g / L): Urea 0.25 g / L, K 2 HPO 4 0.05 g / L, MgSO 4 ·7H 2 O 0.075 g / L, CaCl 2 2H 2 O 50 mg / L, NaCl 100 mg / L, FeCl 3 . 6H 2 O 5 mg / L. Adjust the pH of the medium to 7.5; use microfiltration to sterilize.

[0062] (3) Inoculation and cultivation: inject the above medium into the sterilized column reactor, insert the wet heavy algae cell concentration at 250 mg / L, manually control the light in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com