Efficient vanadium extraction method by performing alkali roasting on vanadium mineral

A mineral and roasting technology, which is applied in the field of high-efficiency vanadium extraction by alkaline roasting of vanadium-containing minerals, can solve the problems of toxic gas acidic ammonia nitrogen wastewater, low vanadium conversion rate recovery rate, low vanadium recovery rate, etc., to achieve high-efficiency leaching and avoid oxidation wrapping And the effect of leaching resistance and saving binder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

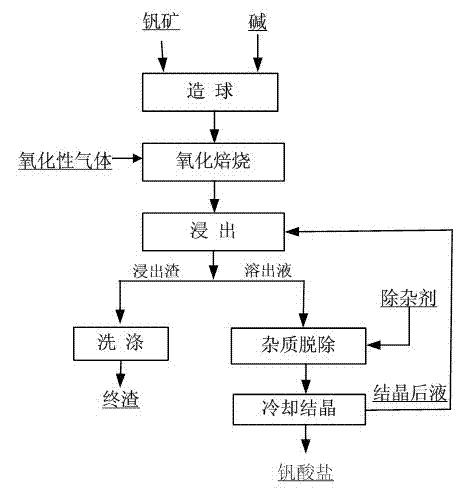

[0018] Example 1: figure 1 As shown, the process steps of the method for efficiently extracting vanadium by alkaline roasting of vanadium-containing minerals are as follows.

[0019] (1) Ingredients: 1kg of vanadium-titanium magnetite and 100g of NaOH are pelletized in a disc granulator to obtain pellets; among them, vanadium-titanium magnetite contains V 2 o 5 1.2wt%, SiO 2 6.5wt%;

[0020] (2) Reaction: Put the pellets into a box kiln and heat them to 350°C for 5 hours. After the reaction, the low-valent vanadium is oxidized to pentavalent and reacts with NaOH to form sodium vanadate to obtain roasted clinker;

[0021] (3) Leaching: leaching the roasted clinker obtained in step (2) in water at 80°C, roasted clinker:water=5:1 (weight); then filter to obtain leaching residue and vanadium-containing eluate;

[0022] (4) Impurity removal: adding a conventional aluminum desiliconization agent to the eluate obtained in step (3) for desiliconization, and filtering to obtain t...

Embodiment 2

[0025] Example 2: The process steps of the method for efficiently extracting vanadium by alkaline roasting of vanadium-containing minerals are as follows.

[0026] (1) Ingredients: 1kg of vanadium slag and 500g of NaOH are pelletized in a disc granulator to obtain pellets; among them, the vanadium slag contains V 2 o 5 12wt%, SiO 2 20wt%;

[0027] (2) Reaction: Put the pellets into a pusher kiln, heat them in oxygen to 500°C for 3 hours, after the reaction, the low-valent vanadium is oxidized to pentavalent and reacts with NaOH to form sodium vanadate to obtain roasted clinker;

[0028] (3) Leaching: Leach the roasted clinker obtained in step (2) in 90°C, 300g / L NaOH solution, the liquid-solid ratio is 5:1 (by weight); then filter to obtain leaching slag and vanadium-containing eluate ;

[0029] (4) Impurity removal: add a conventional calcium desiliconization agent to the eluate obtained in step (3) to remove impurities, and filter to obtain the impurity-removed residue...

Embodiment 3

[0032] Example 3: The process steps of the method for efficiently extracting vanadium by alkaline roasting of vanadium-containing minerals are as follows.

[0033] (1) Ingredients: 1000g of vanadium extraction tailings and 300g of KOH are pelletized in a disc granulator to obtain pellets; among them, the vanadium extraction tailings contain V 2 o 5 2wt%, SiO 2 20wt%;

[0034] (2) Reaction: Put the pellets into the rotary kiln and heat them in oxygen-enriched air to 700°C for 1 hour. After the reaction, the vanadium oxide reacts with KOH to form potassium vanadate to obtain roasted clinker;

[0035] (3) Leaching: Leach the roasted clinker obtained in step (2) in 50°C, 600g / L KOH solution, the liquid-solid ratio is 5:1 (by weight); then filter to obtain leaching slag and vanadium-containing eluate ;

[0036] (4) Impurity removal: add calcium desiliconization agent to the eluate obtained in step (3) to remove impurities, and filter to obtain the impurity-removed residue and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com