Quasi-solid-state polymer gel electrolyte and preparation method thereof

A technology of gel electrolyte and polymer, which is applied in the direction of capacitor electrolyte/absorbent, photovoltaic power generation, photosensitive equipment, etc. It can solve the problems of easy volatilization, unstable photocurrent, and easy chemical changes, etc., and achieve cross-linking and curing reaction conditions Mild, easy to operate preparation method, broad industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] 1. Preparation of a quasi-solid polymer gel electrolyte

[0035] The quasi-solid polymer gel electrolyte polymer includes the following components: polymer macromolecule, crosslinking agent, solvent A, elemental iodine and iodine compound, wherein the solvent A may also contain pyridine or imidazole compounds as additives.

[0036] The preparation method of described quasi-solid polymer gel electrolyte is as follows:

[0037] ① Add solvent A and additives to the container, and mix thoroughly to obtain a mixed solution;

[0038] ②Add elemental iodine and iodine compound into the mixed solution, stir and dissolve to obtain liquid electrolyte;

[0039] ③ Add polymer macromolecules to the liquid electrolyte, add a crosslinking agent after the polymer macromolecules are dissolved, and obtain the precursor of the quasi-solid polymer gel electrolyte after dissolution;

[0040] ④ Curing the quasi-solid polymer gel electrolyte precursor at 50-80°C for 10min-2h, removing the un...

Embodiment 1~ Embodiment 4

[0051] 1. Preparation of Quasi-Solid Polymer Gel Electrolyte

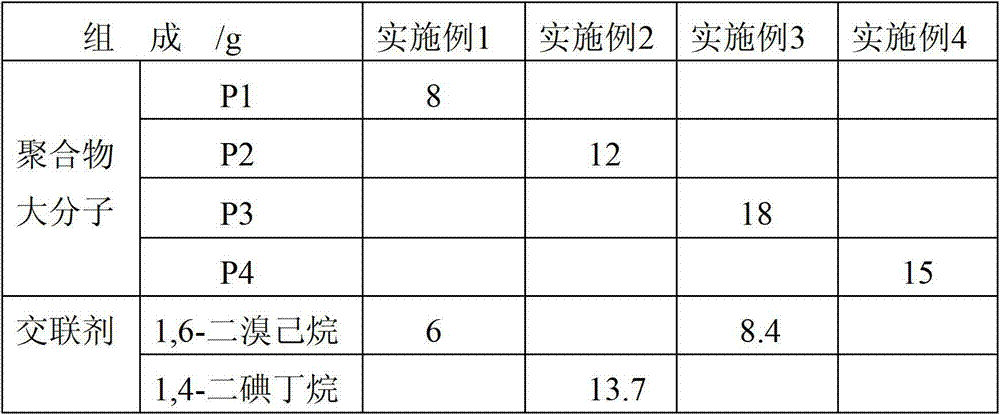

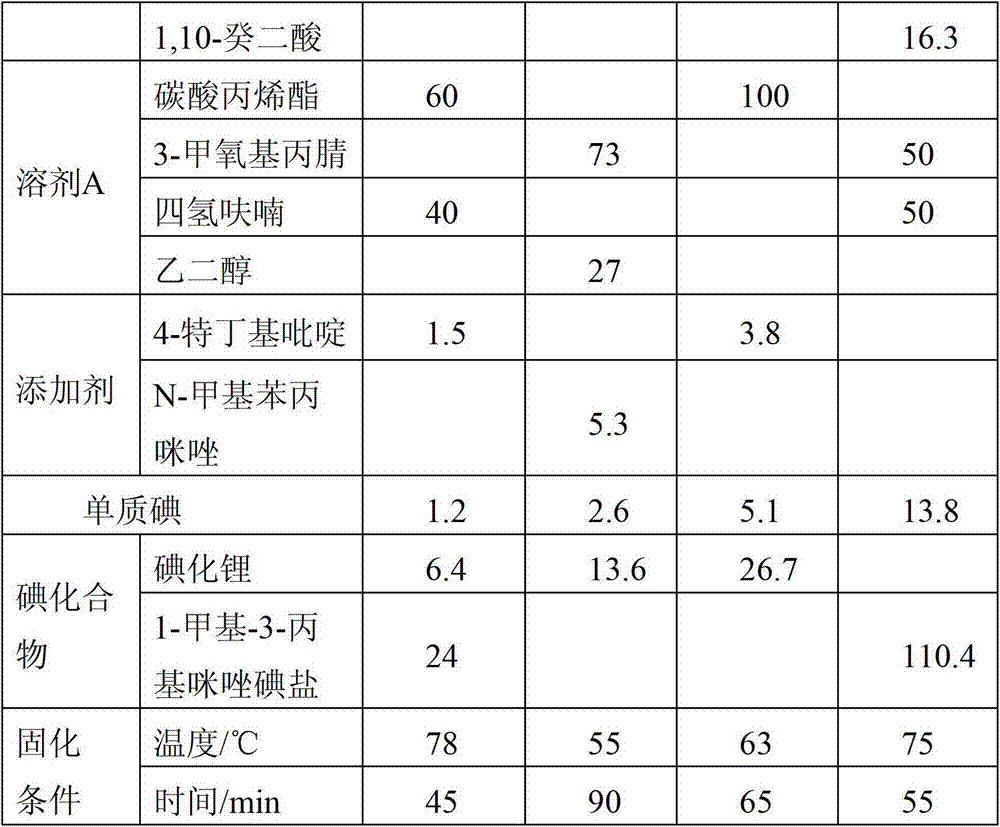

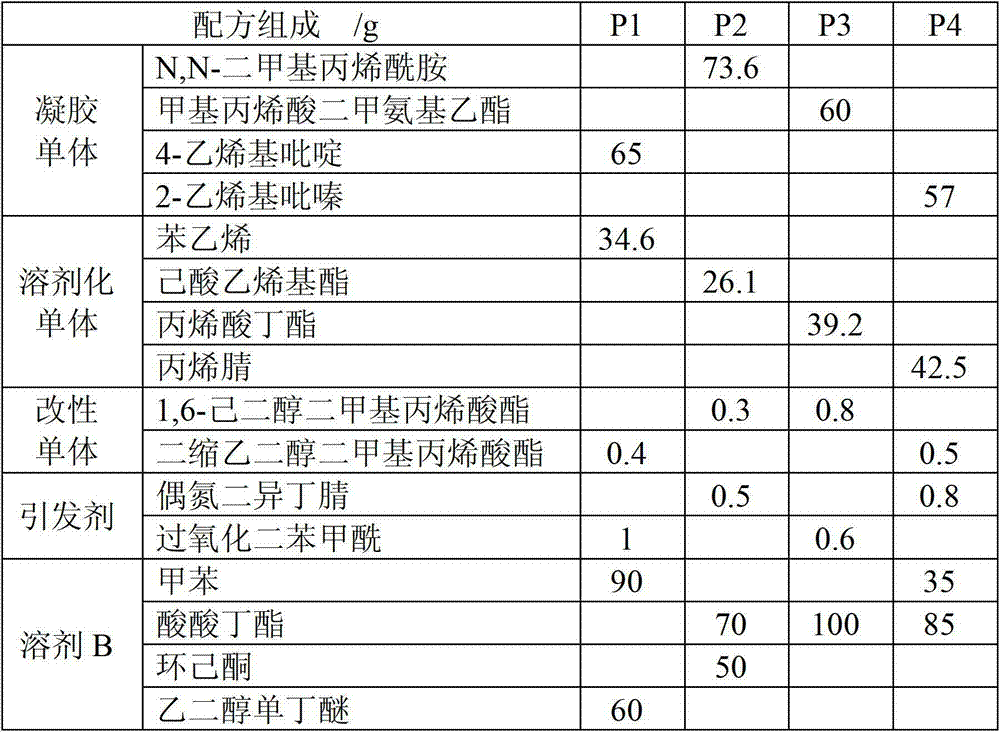

[0052] The composition and content of the quasi-solid polymer gel electrolyte are shown in Table 1. Each component was weighed according to the composition and content in Table 1, and the quasi-solid polymer gel electrolyte was obtained according to the above-mentioned preparation method of the quasi-solid polymer gel electrolyte. The curing conditions in the preparation step ④ are shown in Table 1; the polymerization formula of the polymer macromolecules (P1-P4) in the preparation step ③ is shown in Table 2, and the polymerization method adopts the free radical solution polymerization method, and the specific method is as follows:

[0053] ① Add solvent B into a three-neck flask with a stirrer and a reflux condenser, start stirring, and stir for 5 minutes at a stirring speed of 50 rpm;

[0054] ② Add gel monomer, solvated monomer and modified monomer, stir at 50 rpm for 10 minutes;

[0055] ③Add initiator, 50 rp...

Embodiment 5~ Embodiment 8

[0062] 1. Preparation of Quasi-Solid Polymer Gel Electrolyte

[0063] The composition and content of the quasi-solid polymer gel electrolyte are shown in Table 3. Each component was weighed according to the composition and content in Table 3, and the quasi-solid polymer gel electrolyte was obtained according to the above-mentioned preparation method of the quasi-solid polymer gel electrolyte. The curing conditions in the preparation step ④ are shown in Table 3; the polymerization formula of the polymer macromolecules (P5-P8) in the preparation step ③ is shown in Table 4, and the polymerization method adopts the free radical bulk polymerization method, and the specific method is as follows:

[0064] ① Add gel monomer, solvated monomer and modified monomer into a three-necked flask with a stirrer and a reflux condenser, start stirring, and stir for 5 minutes at a stirring speed of 50 rpm;

[0065] ② Add the initiator, stir at 50 rpm for 10 minutes, and stop stirring;

[0066] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com