Method for reducing irreversible capacity loss of cathode material of lithium ion battery in initial charge

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, electrolytic organic material coatings, electrode manufacturing, etc., can solve problems affecting battery cycle life and safety performance, irreversible capacity loss of lithium-ion batteries, and affecting battery energy density. Achieve the effects of short preparation cycle, uniform and controllable thickness, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

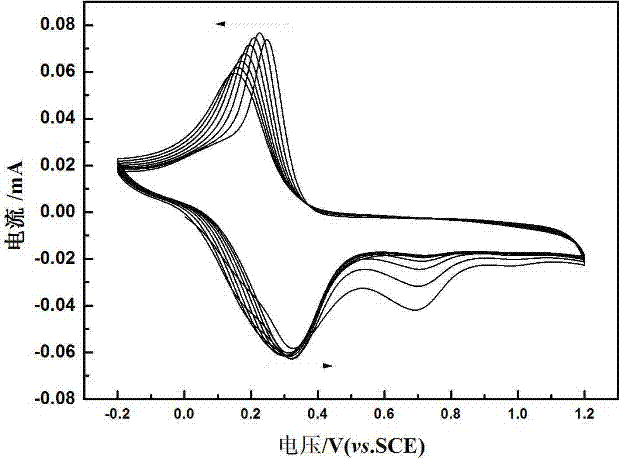

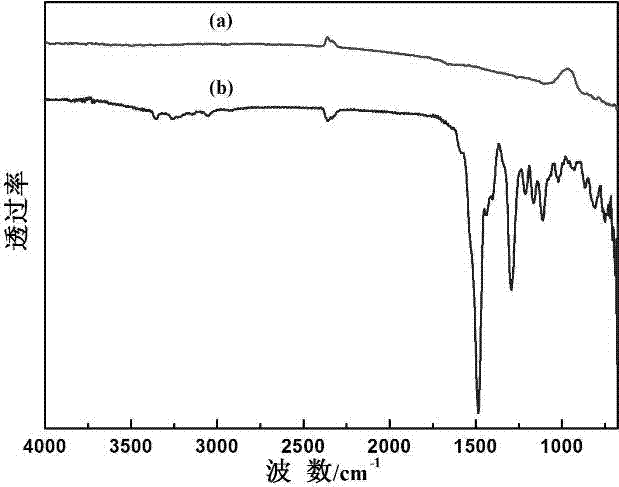

Embodiment 1

[0029] After mixing graphitized carbon fiber, conductive agent Super P, and binder PTFE in a mass ratio of 85:10:5, roll the negative electrode sheet on a double-roller machine and press it on the copper current collector as the negative electrode blank electrode sheet. Prepare 0.1 mol / L sulfuric acid and 0.1 mol / L aniline solution, pass through nitrogen, and dissolve evenly under magnetic stirring. The prepared negative electrode blank electrode was used as the working electrode, the Pt sheet electrode was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode, and the prepared solution was used as the electrolyte to electrodeposit a layer of polymer on the surface of the electrode by cyclic voltammetry. Aniline (PANI). The scanning voltage was -0.2~1.2 V, the scanning rate was 1 mV / s, and the number of scanning segments was 100. The prepared polyaniline film-coated composite electrode was rinsed with deionized water, then wash...

Embodiment 2

[0033] After mixing the graphitized mesophase carbon microspheres, the conductive agent Super P, and the binder PTFE in a mass ratio of 85:10:5, roll the negative electrode sheet on a double-roll machine. Dissolve 50 mmol / L phenol and 0.3 mol / L NaOH in methanol solution under stirring with a magnetic stirrer. In the three-electrode system, the prepared electrode was used as the working electrode, the Pt sheet was used as the counter electrode, the saturated calomel electrode was used as the reference electrode, and the phenol solution was used as the electrolyte. Layer polyphenol (PPO). The scanning voltage range is 0~1.5V, the scanning rate is 10 mV / s, and the number of scanning segments is 30. The thickness of the obtained polymer layer is between 35nm and 50nm.

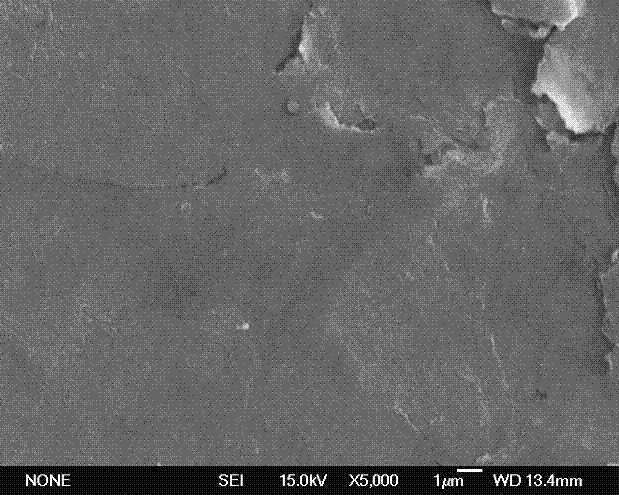

[0034] The SEM of the electrodeposited polyphenol on the surface of the pole piece is shown in image 3As shown, the graphitized mesophase carbon microsphere particles have been well covered, forming a uniform a...

Embodiment 3

[0036] After mixing natural graphite, conductive agent Super P, and binder PTFE in a mass ratio of 85:10:5, roll the negative electrode sheet on a double-roll machine. Dissolve 3 mol / L hydroquinone and 2 mol / L NaOH in methanol solution under stirring with a magnetic stirrer. In the three-electrode system, the prepared electrode is used as the working electrode, the Pt sheet is used as the counter electrode, the saturated calomel electrode is used as the reference electrode, and the hydroquinone solution is used as the electrolyte. Electrodeposit a layer of polyhydroquinone (PHQ). The scanning voltage range is 0-1.5 V, the scanning rate is 25 mV / s, and the number of scanning segments is 50. The thickness of the obtained polymer layer is between 8 and 10 μm.

[0037] Put the pole pieces prepared above in a vacuum oven, bake them at 100°C for 8 hours, and then assemble them into button half cells for electrical performance testing (the negative electrode is a lithium piece, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com