Nano material and application thereof, and method and device for preparing nano material

A nanomaterial and nanotechnology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve difficult problems such as the preparation of nanodevices, and achieve industrial production, easy collaboration, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 Electrospinning device

[0052] The electrospinning device of the present application is improved on the basis of the existing electrospinning device. Specifically, the spinneret and the corresponding wire-connecting plate are designed so that the working distance can be adjusted within 2 to 20 centimeters The movable structure, wherein, the diameter of the spinneret can be 100nm~1cm; in addition, an energy drive device that can provide a voltage of 5~50 kV is specially provided to provide high-voltage static electricity for electrospinning. The rest is the same as the existing electrospinning device.

[0053] The electrospinning device of this example is designed according to the special requirements for preparing the nanomaterials of the present application, and is specially used for the production of the nanomaterials of the present application. The operation is simple and convenient, and it lays the foundation for the industrial production of the nanoma...

Embodiment 2

[0055] The plasma spinning equipment of the present application adopts the plasma arc driven by direct current as the heat source to heat, melt, semi-melt, or atomize the polymer and other materials, and induce high-speed spraying on the surface of the pretreated workpiece by an electrostatic field. method. Improvement is made on the basis of the existing plasma spraying, specifically, on the basis of a conventional plasma spraying device, the spinneret and the corresponding wire-connecting plate are designed so that the working distance can be within 2~20 cm Adjustable movable structure, wherein the diameter of the spinneret can be 100nm~1cm; in addition, an energy drive device that can provide a voltage of 5~50 kV is specially provided to provide high-voltage static electricity for plasma spinning.

[0056] The electrospinning and plasma spinning devices of this example are designed according to the special requirements for preparing the nanomaterials of the present applicat...

Embodiment 3

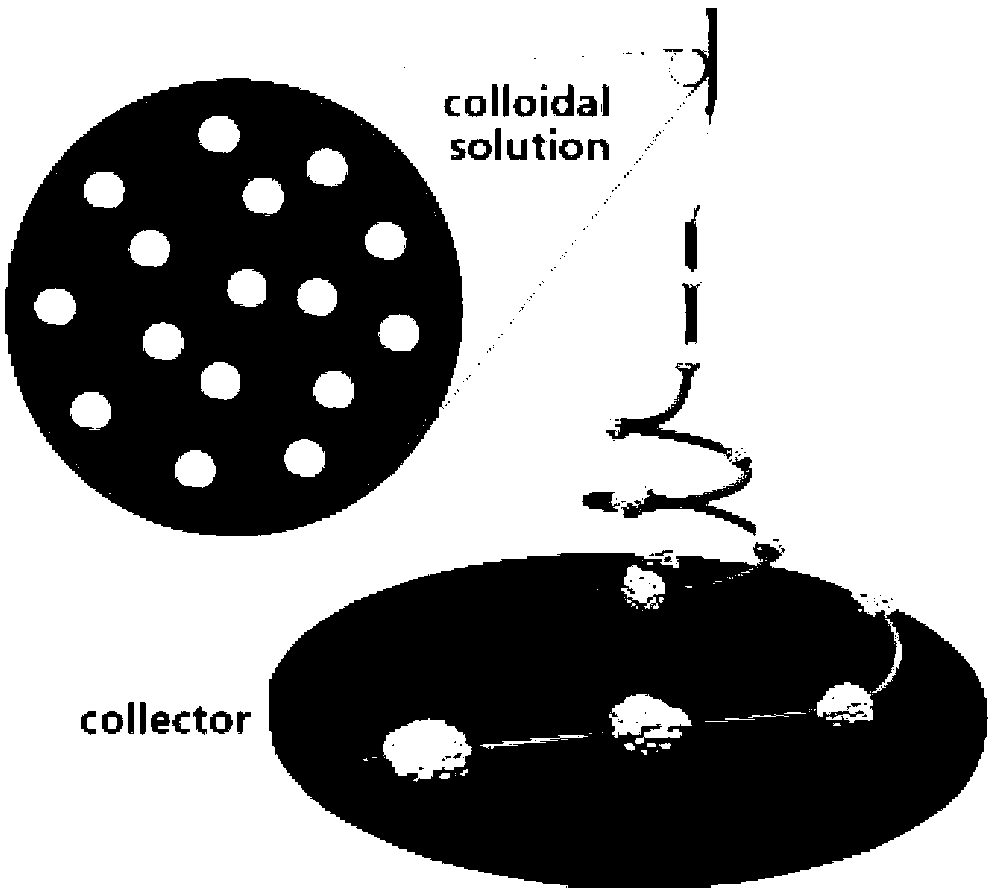

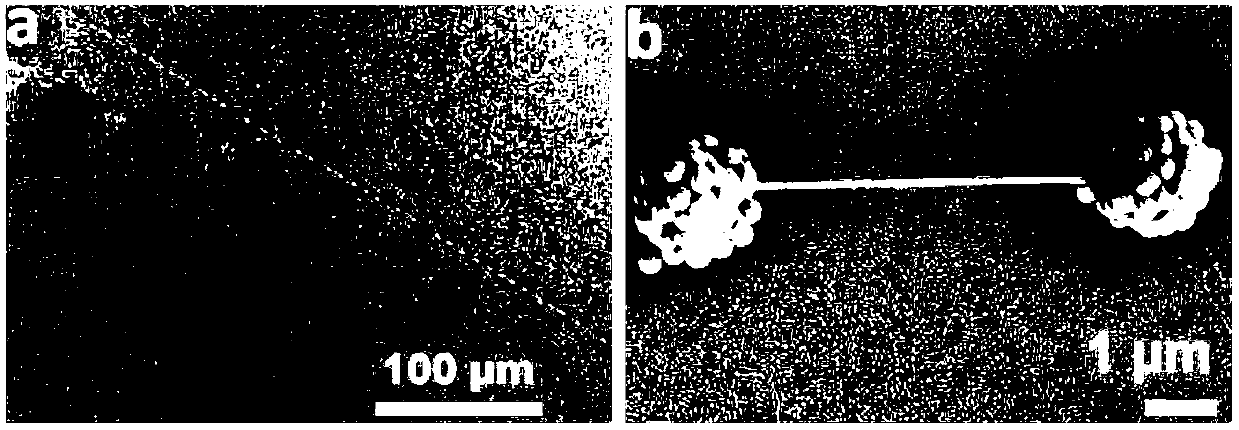

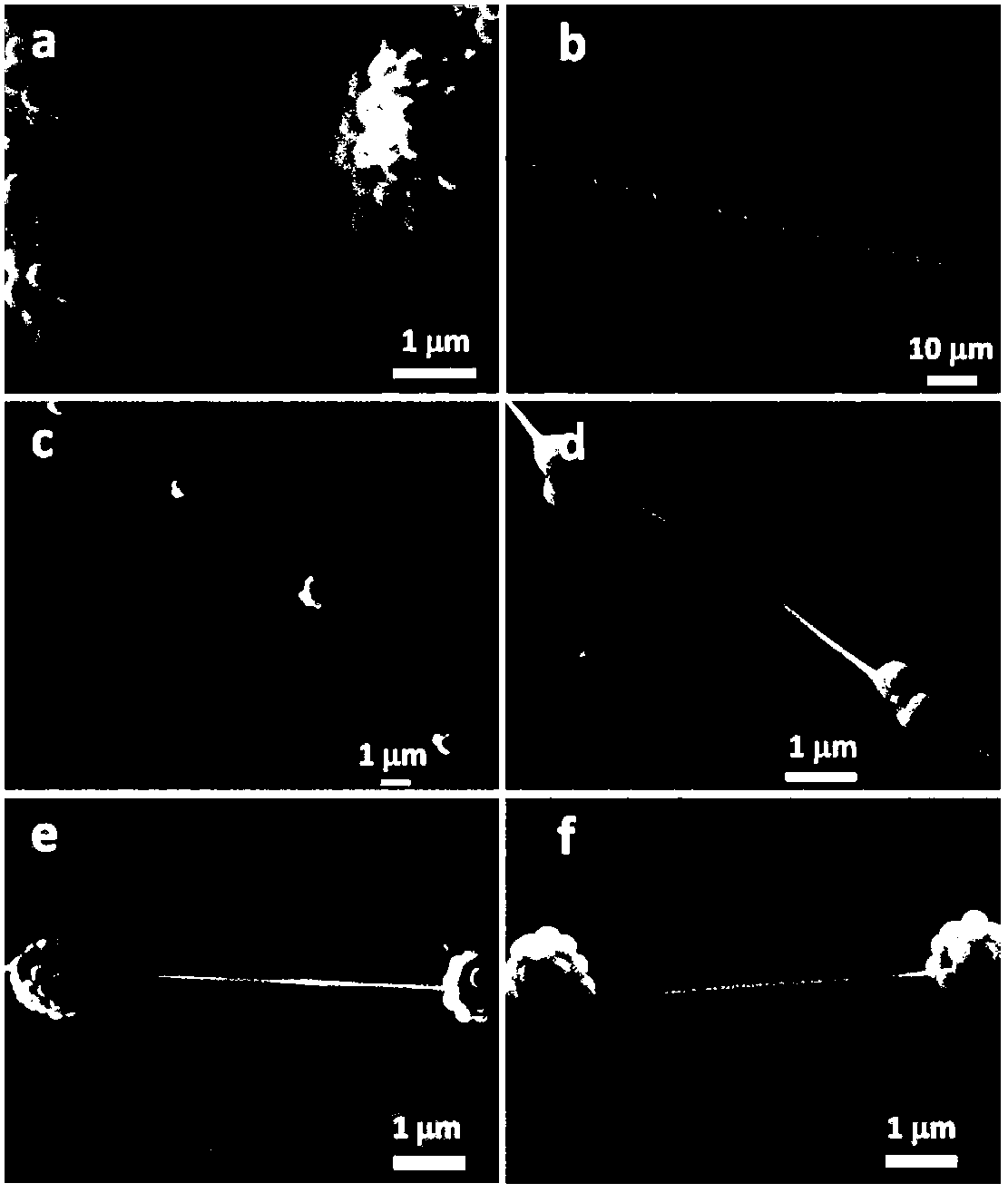

[0058] The nanomaterials of this example were prepared from silica particles and polyvinylpyrrolidone solution. Firstly, the silica particle dispersion with a particle size of 300nm and a concentration of 10% is added to a polyvinylpyrrolidone solution with a concentration of 4% to 20% to prepare an electrospinning precursor. Wherein, the volume ratio of the silica particle dispersion to the polyvinylpyrrolidone solution is 1:2. After preparing the electrospinning precursor, use the electrospinning device of Example 1 to carry out electrospinning, such as figure 1 As shown, the injection speed is controlled by the injection pump at 1mL h -1, the control voltage is 8-18 kV, and the working distance between the wire-connecting plate and the nozzle is controlled to be 5-15 cm. After about 5 minutes, a large number of nano-materials with nano dumbbell-shaped structures can be formed on the wire-connecting plate. . The scanning electron microscope structure of the nanomaterial i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com