System and method for regenerating magnesium oxides and sulfur dioxides through decomposition of magnesium oxide desulphurization by-products

A technology for desulfurization by-products, sulfur dioxide, applied in chemical instruments and methods, magnesium oxide, separation methods, etc., can solve the problems of increasing desulfurization operating costs, waste of resources, etc., and achieve significant economic benefits, high productivity, and fast response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

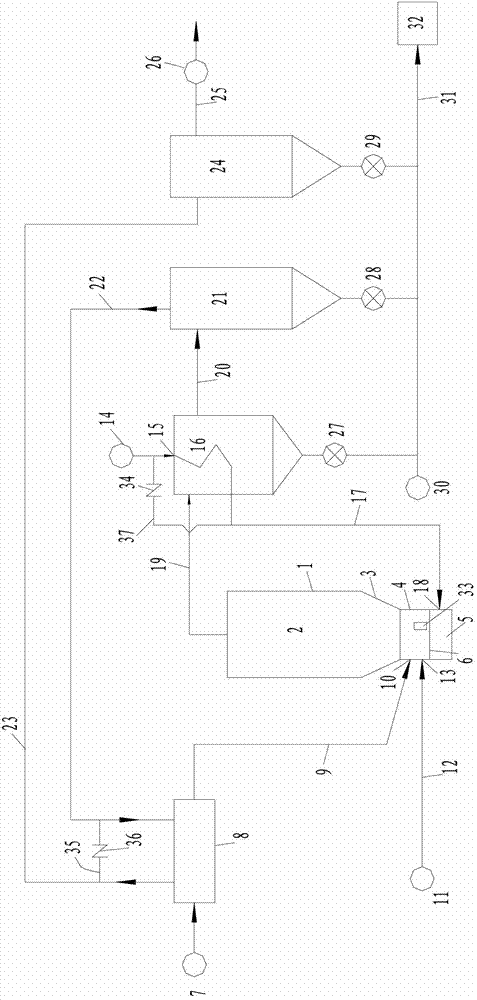

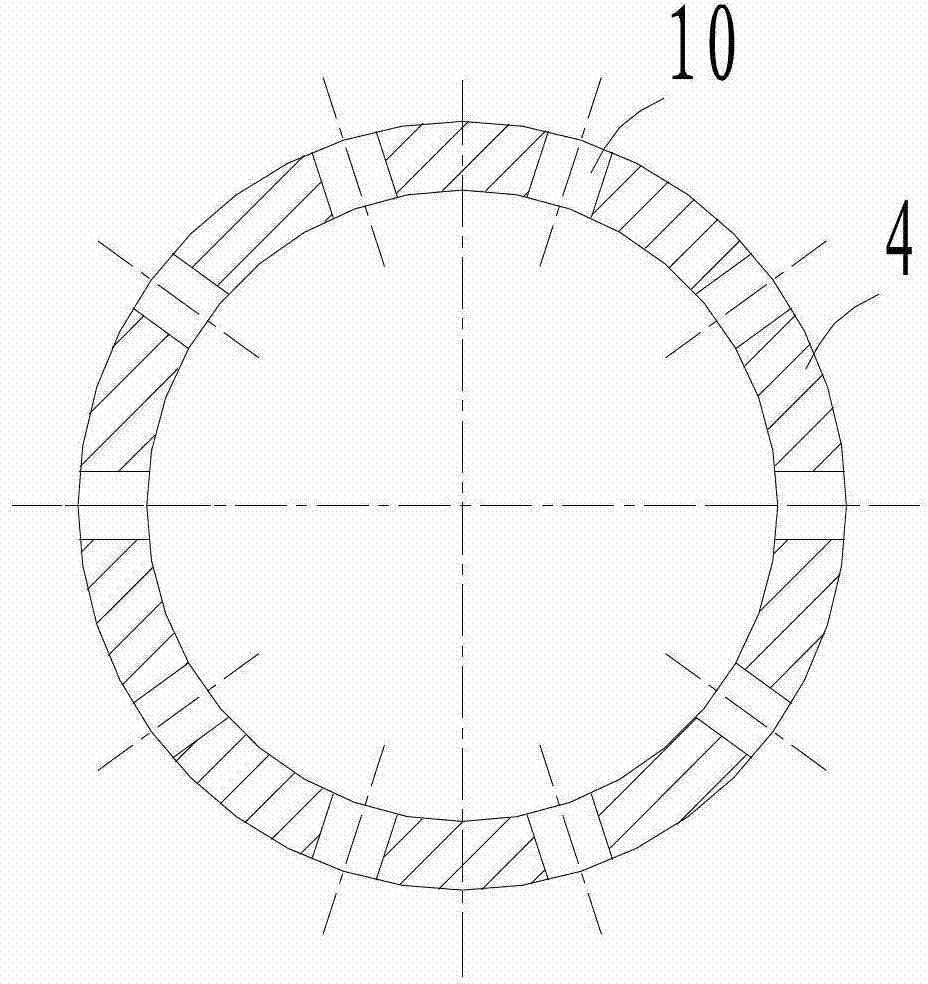

[0042] Such as figure 1 with figure 2 As shown, a system for decomposing magnesium oxide desulfurization by-products to regenerate magnesium oxide and sulfur dioxide includes a regeneration furnace 2, and the regeneration furnace 2 is provided with a by-product feed port 10, a fuel nozzle 13 and an air nozzle 18, and the by-product feed port 10 is connected with the by-product feed pipe 9, the fuel nozzle 13 is connected with the fuel delivery pipe 12, the fuel delivery pipe 12 is connected with the fuel conveyor 11, and the air nozzle 18 is connected with the intake pipe 17. The top of the regeneration furnace 2 is provided with an exhaust pipe 19 .

[0043] The by-product feed pipe 9 is connected to the drier 8 , and the drier 8 is connected to the by-product conveyor 7 . The dryer 8 can be a direct contact dryer between hot furnace gas and solid materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com