Method for comprehensively utilizing trichlorosucrose production waste gas

A technology of sucralose and exhaust gas, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, sulfur compounds, etc., can solve the problems of consuming large alkaline substances and increasing production costs, and achieve the goal of reducing product costs and reducing waste emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

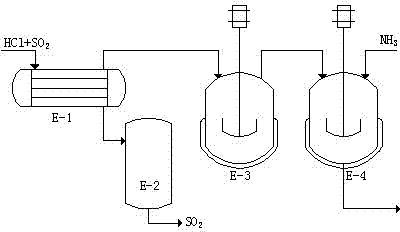

Image

Examples

Embodiment 1

[0018] Embodiment 1: the reaction steps that adopt methyl alcohol are as follows:

[0019] 500.0 g of concentrated sulfuric acid was added to the 1000 ml E-3 reactor, and 480.6 g of methanol and 123.2 g of acetonitrile were added to the 1000 ml E-4 reactor. Keep the E-3 reactor at room temperature, the E-4 reactor temperature at -5°C, and the outlet condensate temperature of the E-1 low-temperature condenser at -30°C. At the rate of 1.2g / min, hydrogen chloride (HCl) and sulfur dioxide (SO 2 ) waste gas (HCl and SO from the chlorination step of sucralose 2 The molar ratio is 2:1), continuous pass for 3 hours. After aeration, keep the temperature of the E-4 reactor at 15°C and continue to react for 3 hours, then pass ammonia at room temperature to adjust the pH value of the solution to 7.5, after adjusting the pH value, continue to stir and react at 25°C for 4 hours to obtain orthoacetic acid Methanol solution of trimethyl ester, trimethyl orthoacetate yield 91.0% (gas ch...

Embodiment 2-10

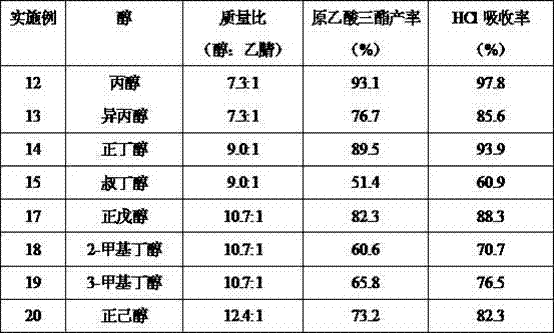

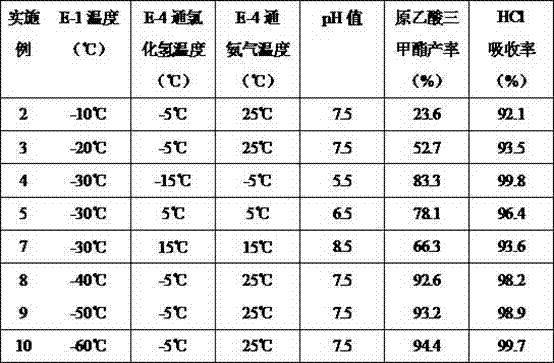

[0021] Similar to Example 1, the results of operating under different conditions are shown in the table below:

[0022]

Embodiment 11

[0023] Example 11, a method for comprehensive utilization of sucralose production waste gas, the reaction steps using ethanol are as follows:

[0024] 500.0 g of concentrated sulfuric acid was added to the 1000 ml E-3 reactor, and 691.1 g of ethanol and 123.2 g of acetonitrile were added to the 1000 ml E-4 reactor. Keep the E-3 reactor at room temperature, the E-4 reactor temperature at -5°C, and the outlet condensate temperature of the E-1 low-temperature condenser at -30°C. At the rate of 1.2g / min, hydrogen chloride (HCl) and sulfur dioxide (SO 2 ) waste gas (HCl and SO from the chlorination step of sucralose 2 The molar ratio is 2:1), continuous pass for 3 hours. After aeration, keep the temperature of the E-4 reactor at 15°C and continue to react for 3 hours, then pass ammonia at room temperature to adjust the pH value of the solution to 7.5, after adjusting the pH value, continue to stir and react at 25°C for 4 hours to obtain orthoacetic acid Ethanol solution of triet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com