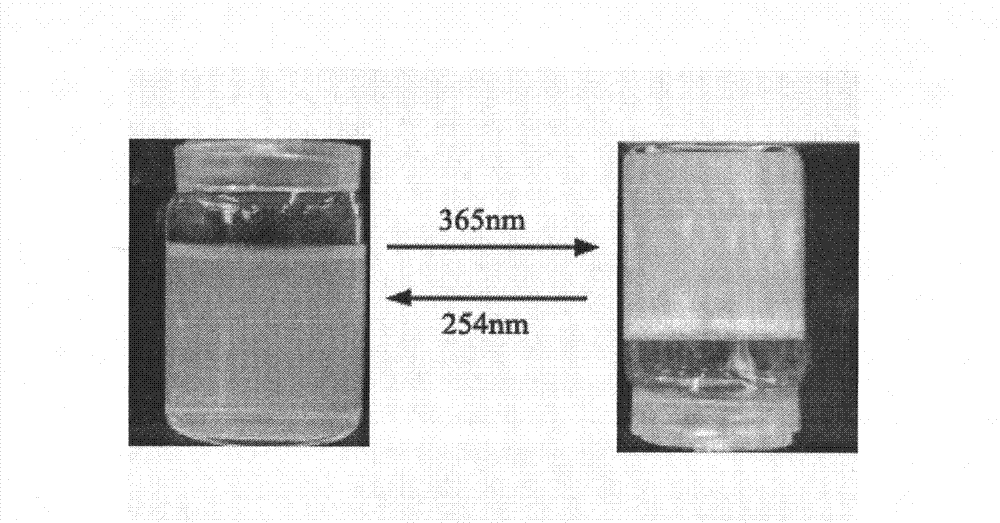

Photoresponsive reversible chitosan hydrogel and preparation method thereof

A light-responsive, chitosan technology, used in medical science, absorbent pads, bandages, etc., can solve the problems of difficult mixing of glutaraldehyde and chitosan aqueous solution, non-reversibility, and a large number of gels. Good biodegradability, low price, accelerated healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

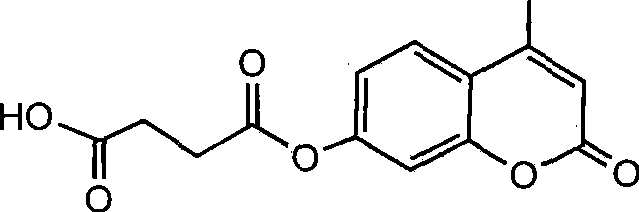

[0015] Example 1 Reversible preparation of light-responsive chitosan and its sol-gel

[0016] (1) Preparation of water-soluble carboxymethyl chitosan

[0017] 15g chitosan (M n =5.6×10 5 Da, DD=96%) and 200mL isopropanol are added in the dry three-necked bottle of 500mL, stir to make chitosan evenly dispersed in isopropanol, 50% (50g NaOH+50g H 2 O) 50 mL of NaOH solution was divided into 5 parts, one part was added every 30 min, and stirred at room temperature for 1 hour to obtain a reactant slurry. Dissolve 24g of solid chloroacetic acid in 70mL of isopropanol, and add it to the reactant slurry in 4 times. After the addition, the reactant was heated to 60° C. in a water bath, and the reflux condensing device was turned on under temperature control, and the reaction was stirred for 4 hours. Then the pH value was adjusted to 7-8 with glacial acetic acid, and a large amount of light yellow flocculent precipitates were precipitated, which was vacuum filtered to obtain a ligh...

Embodiment 2

[0025] Example 2 Reversible preparation of light-responsive chitosan and its sol-gel

[0026] (1) Preparation of water-soluble carboxymethyl chitosan

[0027] 20g chitosan (M n =5.6×10 5 Da, DD=96%) and 200mL isopropanol are added in the dry three-necked bottle of 500mL, stir to make chitosan evenly dispersed in isopropanol, 50% (50g NaOH+50g H 2 O) 60 mL of NaOH solution was divided into 3 parts, one part was added every 30 min, and stirred at room temperature for 1 hour to obtain a reactant slurry. Dissolve 30 g of solid chloroacetic acid in 80 mL of isopropanol, and add it to the reactant slurry in four portions. After the addition, the reactant was heated to 70° C. in a water bath, and the reflux condensing device was turned on under temperature control, and the reaction was stirred for 2 hours. Then the pH value was adjusted to 7-8 with glacial acetic acid, and a large amount of light yellow flocculent precipitates were precipitated, which was vacuum filtered to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com