Method for preventing volatilization and achieving electromagnetic shielding by processing surface of organic matter component

A technology of electromagnetic shielding and organic matter, which is applied in the fields of magnetic field/electric field shielding, electrical components, vacuum evaporation plating, etc., can solve the problems of difficult mass production, low processing pass rate, complex shape of components, etc., and achieve low cost and excellent preparation process Proven and Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

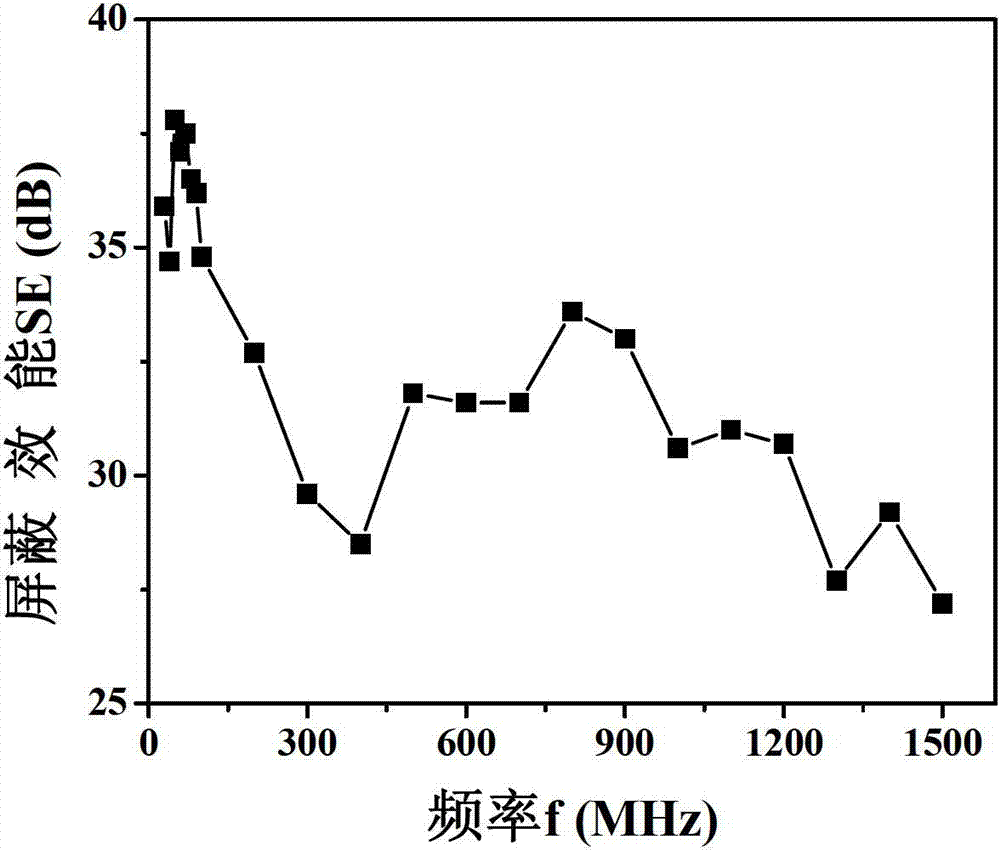

Embodiment 1

[0026] Metal Ni monolayer film was deposited by magnetron sputtering system, the target material was Ni with a purity of 99.9%, the purity of argon gas was 99.9%, and the background pressure of the vacuum chamber was 3×10 -4 Pa, the rotating speed of the workpiece holder is 20 rpm. Cleaning of the workpiece to be plated and clamping of the workpiece: Ultrasonic cleaning and dehydration of the workpiece to be plated are carried out with detergent, deionized water, and absolute ethanol respectively. The cleaning time is 10 minutes each time. After drying, transfer it to the work frame for plating. Turn on the mechanical pump and the molecular pump to evacuate until the pressure is lower than 3×10 -4 After Pa, 20 sccm of argon gas is input into the vacuum chamber, so that the pressure in the vacuum chamber is 1 Pa. Turn on the RF power supply, adjust the matcher, glow discharge occurs in the vacuum chamber, increase the incident power, and perform plasma etching cleaning on the ...

Embodiment 2

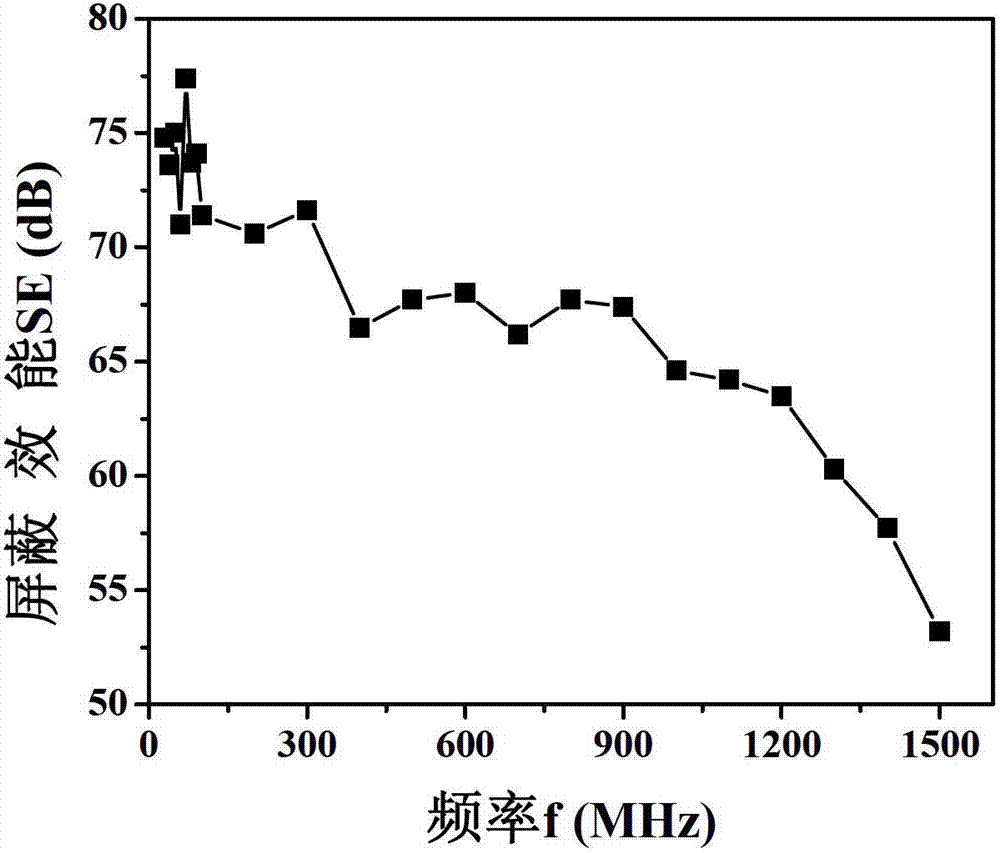

[0029] The metal Cu / Ni / Cu multilayer film is deposited by magnetron sputtering system, the target material is Cu and Ni with a purity of 99.9%, the purity of argon gas is 99.9%, and the background pressure of the vacuum chamber is 5×10 -4 Pa, the rotating speed of the workpiece holder is 30 rpm. Cleaning of the workpiece to be plated and clamping of the workpiece: Ultrasonic cleaning and dehydration of the workpiece to be plated are carried out with detergent, deionized water, and absolute ethanol respectively. The cleaning time is 10 minutes each time. After drying, transfer it to the work frame for plating. Turn on the mechanical pump and the molecular pump to evacuate until the pressure is lower than 5×10 -4 After Pa, 20 sccm of argon gas is input into the vacuum chamber, so that the pressure in the vacuum chamber is 1 Pa. Turn on the power, adjust the matcher, glow discharge occurs in the vacuum chamber, increase the incident power, and perform plasma etching cleaning on ...

Embodiment 3

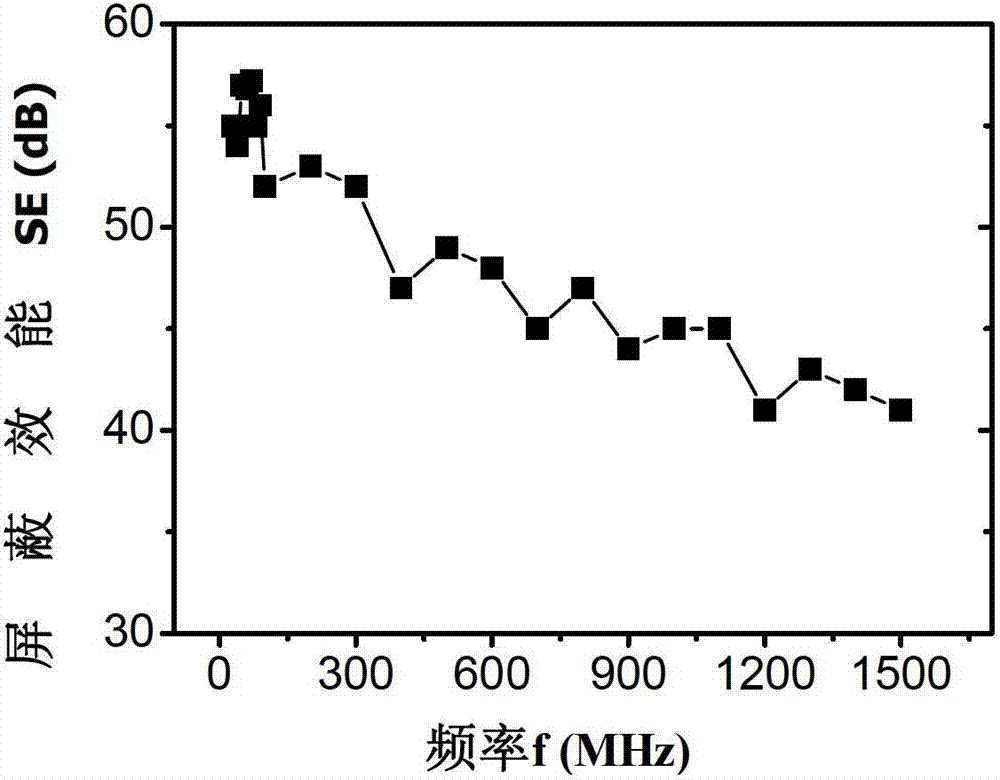

[0032] A magnetron sputtering system was used to deposit a nickel-copper composite metal coating, the target materials were Cu and Ni with a purity of 99.9%, the purity of argon gas was 99.9%, and the background pressure of the vacuum chamber was 5×10 -4 Pa, the workpiece holder rotates at 10 rpm. Cleaning of the workpiece to be plated and clamping of the workpiece: Ultrasonic cleaning and dehydration of the workpiece to be plated are carried out with detergent, deionized water, and absolute ethanol respectively. The cleaning time is 10 minutes each time. After drying, transfer it to the work frame for plating. Turn on the mechanical pump and the molecular pump to evacuate until the pressure is lower than 1×10 -4 After Pa, 20 sccm of argon gas is input into the vacuum chamber, so that the pressure in the vacuum chamber is 1 Pa. Turn on the power, adjust the matcher, glow discharge occurs in the vacuum chamber, increase the incident power, and perform plasma etching cleaning o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com