Affinity adsorption biodegradation membrane and preparation method thereof

A biodegradable membrane and affinity technology, applied in chemical instruments and methods, biological water/sewage treatment, and other chemical processes, can solve problems such as high treatment costs, residual nano-microspheres, and highly toxic secondary pollutants. Achieve the effects of high adsorption and degradation efficiency, high adsorption specificity, and resistance to interference from impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Degradation of BPA in pure water by affinity adsorption biodegradable membrane

[0044] Accurately weigh several 10mg membranes (group A: bacteria+MIM; group B: bacteria+nMIM; group C: dominant bacteria) and add them into 20mL spiked pure water (BPA=500μg / L) to start the degradation reaction. At each reaction termination time point (0, 3, 6, 12, 24h), take parallel samples, centrifuge the reactant at a speed of 6000rpm / min for 3min, and detect BPA in the solid phase (membrane + bacteria) and water phase respectively . Add 3mL methanol into the solid phase and soak for 10min; add 15mL dichloromethane into the water phase three times, shake and extract for 3min each time, collect and combine the organic phases, evaporate to dryness on a nitrogen blower (50°C), and redissolve the residue in 1mL of acetonitrile, and then detected by liquid chromatography-mass spectrometry. It was found that the 24h degradation rate of bacteria+MIM BPA was 47.25%, which was sign...

Embodiment 2

[0045] Example 2: BPA in pure water with heavy metal lead ions degraded by affinity adsorption biodegradable membrane

[0046] Accurately weigh several 10mg films (group A: bacteria+MIM; group B: bacteria+nMIM; group C: dominant bacteria) and add them into 20mL spiked pure water containing lead (BPA=500μg / L, Pb(CH 3 COO) 2 =1mg / L) to start the degradation reaction. At each reaction termination time point (0, 3, 6, 12, 24h), take parallel samples, centrifuge the reactant at a speed of 6000rpm / min for 3min, and detect BPA in the solid phase (membrane + bacteria) and water phase respectively . Add 3mL methanol into the solid phase and soak for 10min; add 15mL dichloromethane into the water phase three times, shake and extract for 3min each time, collect and combine the organic phases, evaporate to dryness on a nitrogen blower (50°C), and redissolve the residue in 1mL of acetonitrile, and then detected by liquid chromatography-mass spectrometry. Find to utilize bacterium+MIM o...

Embodiment 3

[0047] Example 3: BPA in pure water with heavy metal cadmium ions degraded by affinity adsorption biodegradable membrane

[0048] Accurately weigh several 10mg films (group A: bacteria+MIM; group B: bacteria+nMIM; group C: dominant bacteria) and add 20mL of cadmium-containing pure water (BPA=500μg / L, CdCl 2 =1mg / L) to start the degradation reaction. At each reaction termination time point (0, 3, 6, 12, 24h), take parallel samples, centrifuge the reactant at a speed of 6000rpm / min for 3min, and detect BPA in the solid phase (membrane + bacteria) and water phase respectively . Add 3mL methanol into the solid phase and soak for 10min; add 15mL dichloromethane into the water phase three times, shake and extract for 3min each time, collect and combine the organic phases, evaporate to dryness on a nitrogen blower (50°C), and redissolve the residue in 1mL of acetonitrile, and then detected by liquid chromatography-mass spectrometry. Find to utilize bacterium+MIM of the present inv...

PUM

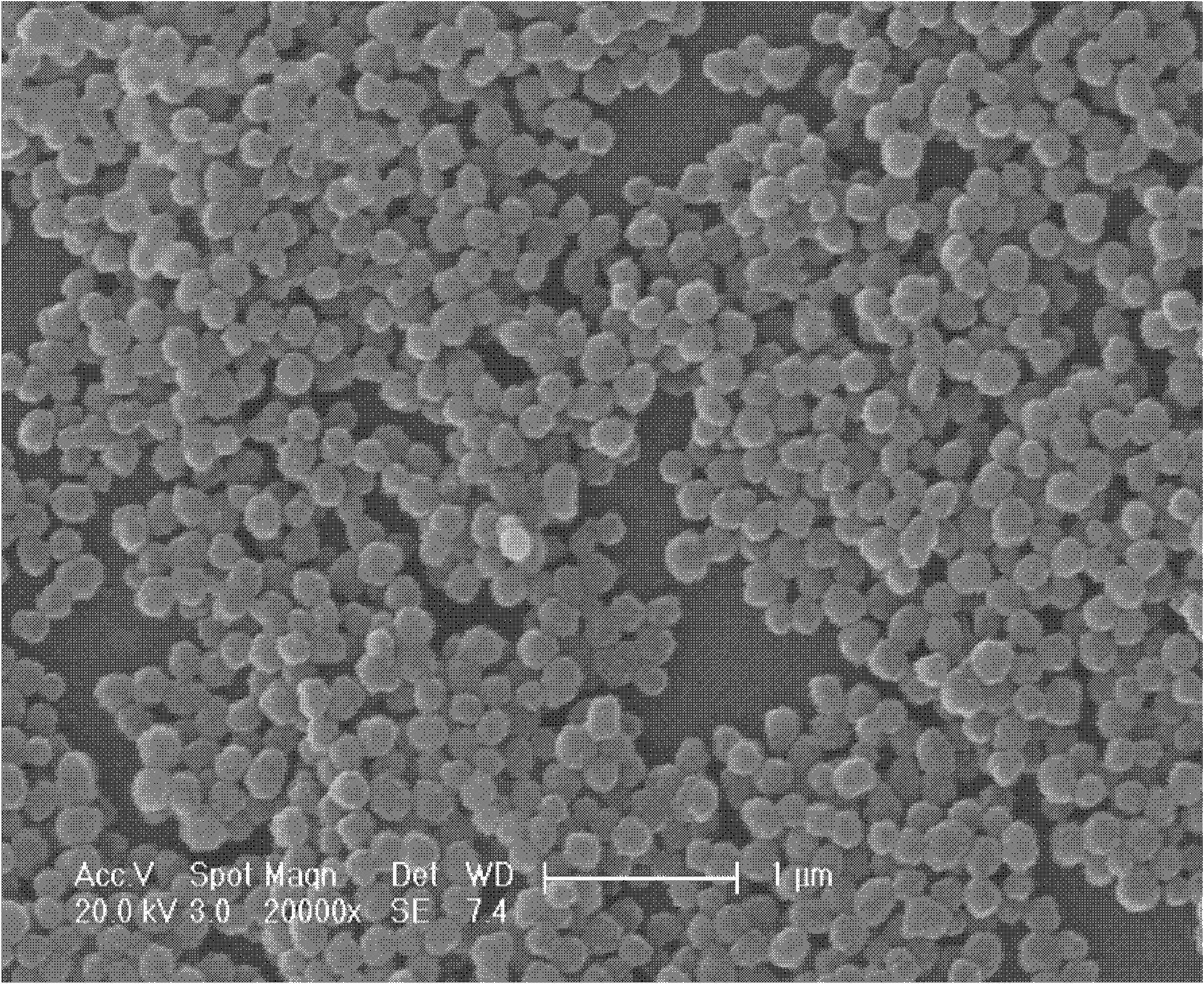

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com