Calcium pectinate and production method and application thereof

A production method and technology of pectin calcium, which are applied in the field of pectin calcium extraction, can solve the problems of no production of commercial pectin calcium products, no production of pectin calcium products, no production of high-methoxy pectin calcium products, etc., and achieve No toxic side effects, save energy and cost, less investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

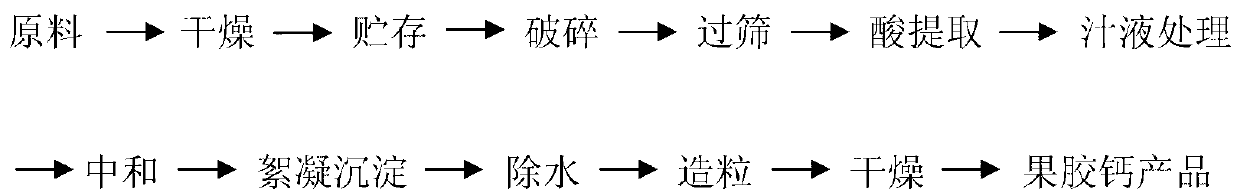

[0034] Embodiment 1 (production process such as figure 1 shown)

[0035] After crushing 100Kg of dried citrus peels, sieve them to obtain particles with a particle size of 20 mesh, add them to 1600Kg of water, boil for 15 minutes, add concentrated hydrochloric acid, adjust the pH to 2.5, keep it in a slightly boiling state for 1 hour, filter it with a cloth bag while it is hot, and take it out Serum for later use. The residue was extracted again in the same way, and the filtrates were combined to obtain about 3200Kg of acid extract.

[0036] Add 2Kg sodium sulfite and 10Kg activated carbon to the acid extract successively, stir at 40°C for 15 minutes for decolorization; then add 10Kg diatomite, stir well and filter with a filter press to obtain the filtrate; add 1mol / L ammonia water to adjust the pH of the filtrate to 7.5 , to obtain pectin extract.

[0037] Add 10mol calcium chloride to the pectin extract, stir evenly, and let it stand for 0.2h to separate the formed pecti...

Embodiment 2

[0038] Embodiment 2 (production process such as figure 1 shown)

[0039] Add 100Kg of mangosteen peel slag powder that has been extracted with more than 70% ethanol into 600Kg of water, boil for 10 minutes, add concentrated hydrochloric acid, adjust the pH to 1.5, keep it in a slightly boiling state for 0.5 hours, filter it with a cloth bag while it is hot, and obtain the acid extract About 600Kg.

[0040] Add 0.5Kg sodium bisulfite and 3Kg activated carbon to the acid extract successively, stir and decolorize at 60°C for 30min; then add 6Kg diatomaceous earth, stir well and filter with a filter press to obtain the filtrate; add 1mol / L NaOH to adjust The pH of the filtrate was 10, and a pectin extract was obtained.

[0041] Add 15 mol calcium dihydrogen phosphate to the pectin extract, stir evenly, and let stand for 1 hour to separate the formed calcium pectin solution. The supernatant is removed, and the flocculated and precipitated pectin calcium is squeezed to remove wat...

Embodiment 3

[0042] Embodiment 3 (production process such as figure 1 shown)

[0043]Add 100Kg of fresh dragon fruit peel powder to 300Kg of water, boil for 5 minutes, add concentrated hydrochloric acid, adjust the pH to 2.5, keep it in a slightly boiling state for 1.5 hours, filter it with a cloth bag while it is hot, and obtain about 300Kg of acid extract.

[0044] Add 0.3Kg sodium bisulfite and 1.5Kg activated carbon to the acid extract in turn, stir and decolorize at 50°C for 30min; then add 4Kg diatomaceous earth, stir well and filter with a filter press to obtain the filtrate; add 1mol / L NaOH to adjust The pH of the filtrate was 8.5, and a pectin extract was obtained.

[0045] Add 10 mol of calcium hydroxide to the pectin extract, stir evenly, and let stand for 1 hour to form layers of pectin calcium solution. The supernatant is removed, and the flocculated and precipitated pectin calcium is squeezed to remove water by using a plate and frame press to obtain a pectin calcium filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com