Method for manufacturing rhodiola fermentation product by using adsorbent

A manufacturing method, the technology of Rhodiola rosea, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the undisclosed problems that are beneficial to human body absorption, and achieve the effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0053] Production example 1: Production of fermented product of Rhodiola rosea alone

[0054] A. Materials

[0055] The main raw material Rhodiola rosea (Rhodiola rosea, figure 1 ) was purchased from China in 2010, after micro-grinding, a pulverizer (Cyclotec TM 1093, FOSS Co., Denmark) was used for powdering. Red ginseng uses commercially available red ginseng powder (NH Korean ginseng, 6-year-old root).

[0056] The strains used in this experiment utilized 10 species of lactic acid bacteria belonging to the genus Lactobacillus, Pediococcus, and Bifidobacterium deposited at the Korea Food Research Institute shown in Table 1. The strains were suspended in sterile 50% glycerol and stored in a deep freezer at -70°C for a long time.

[0057] Table 1

[0058] differentiate

strain name

medium used

L1

Lactobacillus acidophilus 128

MRS

L2

Lactobacillus plantarum 144

MRS

L3

MRS

...

experiment example 1

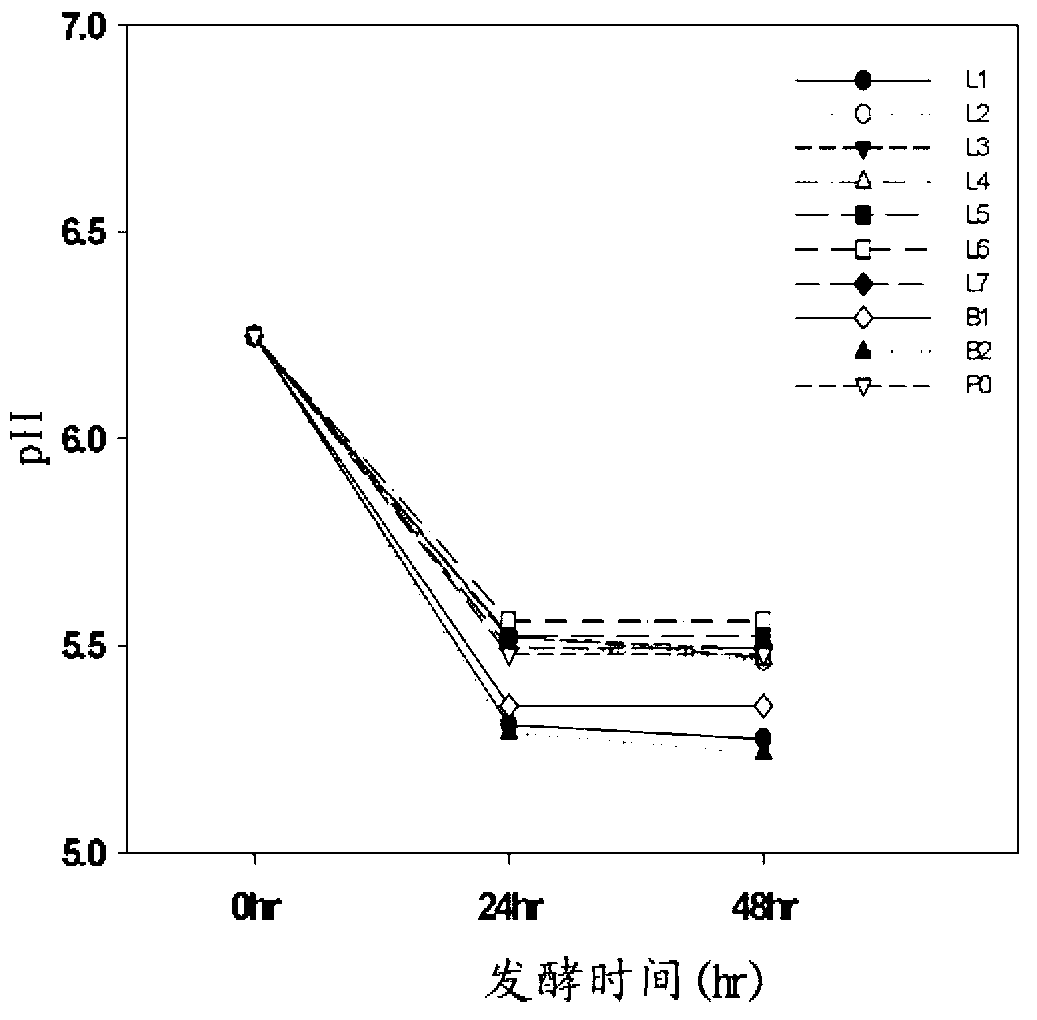

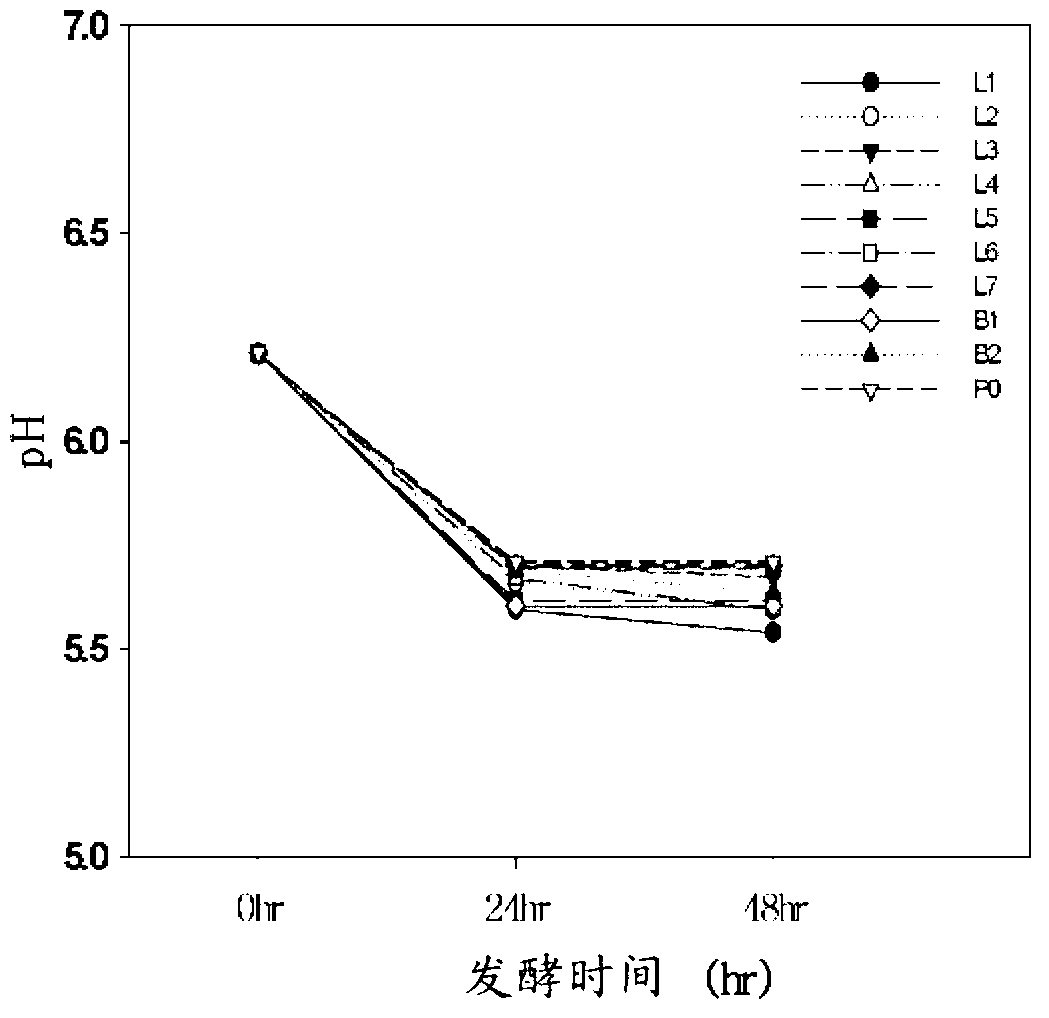

[0064] Experimental Example 1: Confirmation of Fermentation Properties of Rhodiola Solo Fermentation Product

[0065] In order to confirm the fermentation characteristics of the Rhodiola rosea extract-only fermented product of Production Example 1, changes in the pH value and the number of viable cells of the fermented product at 24 hours and 48 hours after inoculation were confirmed.

[0066] The number of viable bacteria is calculated as follows: Dilute 1ml of the sample with 9ml of sterilized physiological saline and mix thoroughly, then dilute step by step, take 0.1ml, smear on MRS agar, double Smear the genus Bifidobacterium on BL agar containing 5% horse blood, use the anaerobic culture tank (BBL Gas Pak anaerobic system), store it in an anaerobic state as much as possible, and culture it at 37°C for 24 to 48 hours. The number of colonies generated was determined, and the average number of colonies was multiplied by the dilution factor to calculate the number of colonies...

manufacture example 2

[0087] Production example 2: Production of Rhodiola fermented product

[0088] A. Sorbent treatment of Rhodiola rosea extract

[0089] The characteristics and application fields of the 11 kinds of adsorbents used in the adsorbent treatment of Rhodiola rosea extract are sorted out and shown in Table 4.

[0090] Table 4

[0091]

[0092] In 100ml of Rhodiola rosea hot water extract (1% solid content, pH 6.46) in Production Example 1, 50g of 11 kinds of adsorbents were treated respectively, and the pH and solid content of the filtered filtrate were measured, as shown in Table 5. show.

[0093] table 5

[0094]

[0095] As shown in Table 5, the Rhodiola rosea extract with an initial solid content of 1% showed a pH value of 4.10, and for the pH value of the filtrate filtered after the adsorbent treatment, the pH value of the filtered filtrate was tested after using activated carbon, activated clay, acid clay, Dowex MWA- 1. When treated with Amberlite IRC-50, it decreases ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com