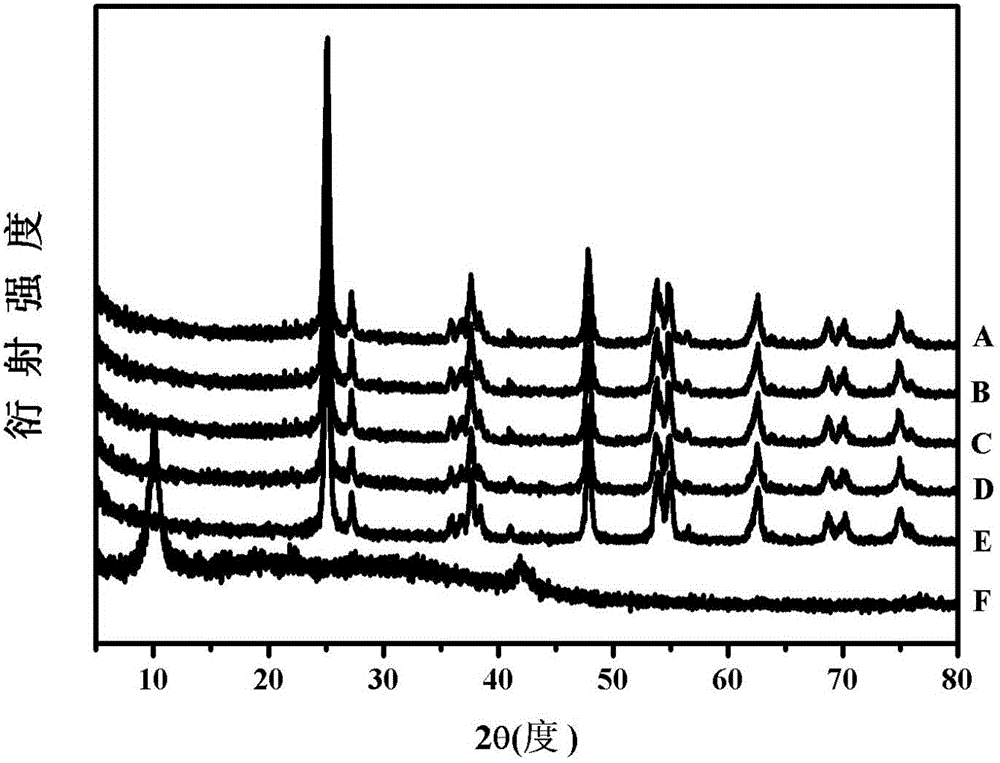

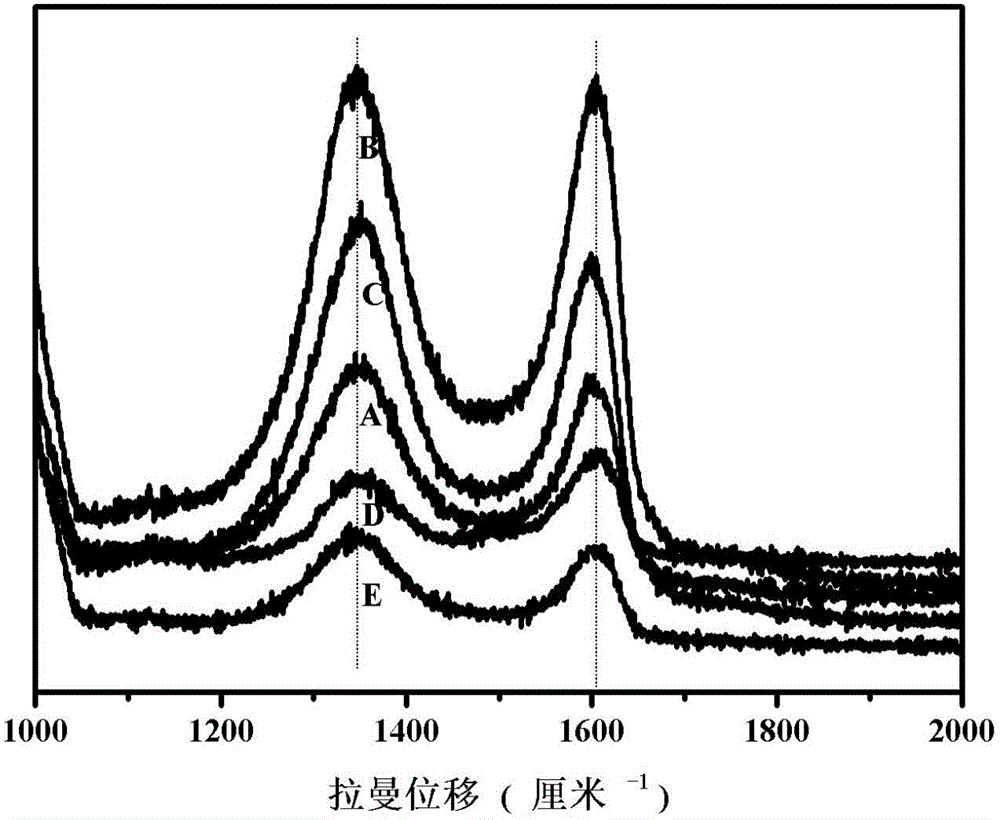

Preparation method of composite material of graphene oxide and titanium oxide nano particles

A nanoparticle and composite material technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of easy agglomeration on the surface of titanium dioxide nanoparticles, reduced photocatalytic activity, and no obvious improvement. , to achieve excellent catalytic performance, improved photocatalytic efficiency, and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Weigh 2g of graphite powder, add 1.5g of sodium nitrate into the Erlenmeyer flask and mix, add 67.5ml of concentrated sulfuric acid and place it on a magnetic stirrer for stirring. Under ice-bath conditions, gradually add 9 g of potassium permanganate for about 1 hour, take it out after stirring for 2 hours under ice-bath conditions, and stir at room temperature for 5 days.

[0035] 2) Add 200ml of sulfuric acid with a mass fraction of 5% to the Erlenmeyer flask dropwise, and stir for 2 hours. After adding 6ml of hydrogen peroxide dropwise into the Erlenmeyer flask, the color of the solution turned bright yellow, and stirred for 2 hours.

[0036] 3) Take the upper liquid and centrifuge, wash with a mixed solution of sulfuric acid with a mass fraction of 3% and hydrogen peroxide with a mass fraction of 10.5% until the pH is neutral, put the obtained precipitate in a vacuum drying oven, and dry at 80°C for 24 hours, that is Get graphite oxide.

[0037] 4) The mass of...

Embodiment 2

[0043] Embodiment 1 step 5) reaction temperature is changed to 150 DEG C, all the other steps are identical with embodiment 1, test sampling and test process are the same as embodiment 1 step 7), the photocatalytic efficiency of result graphene oxide and titanium dioxide nano particle composite material and Titanium dioxide P25 is close, and the dye can be degraded by 50% under no-light conditions. After continuing to increase ultraviolet radiation, the dye can be further degraded.

Embodiment 3

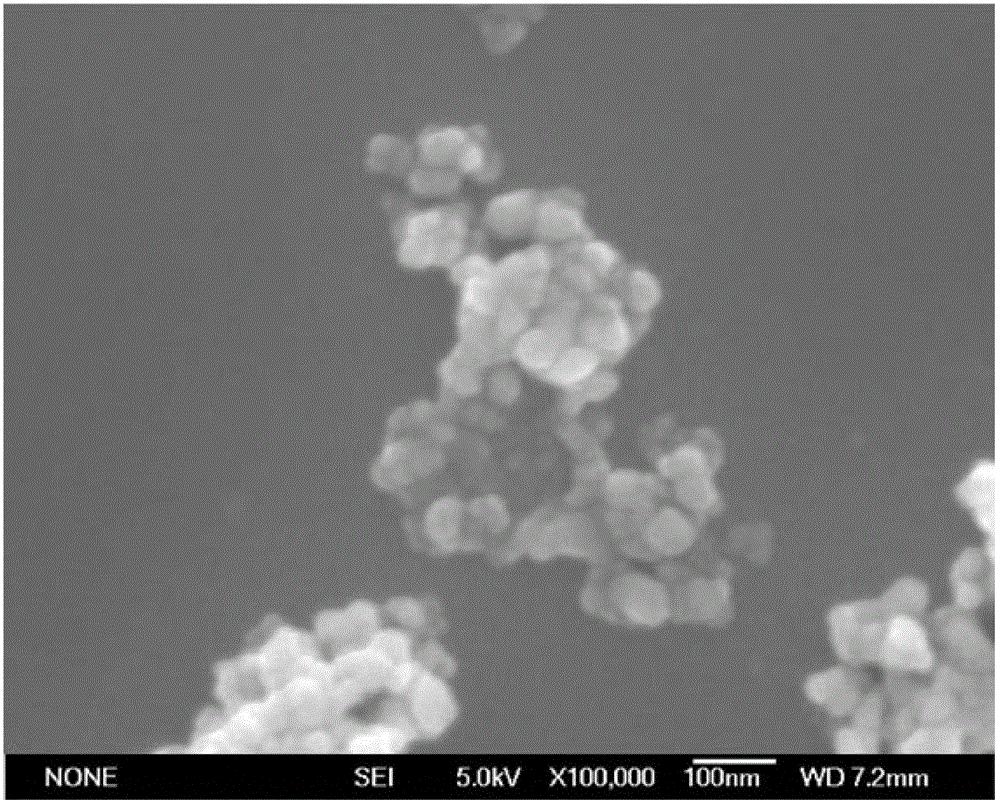

[0045] Embodiment 1 step 5) reaction temperature is changed to 120 ℃, all the other steps are the same as embodiment 1, and the obtained graphene oxide and titanium dioxide nanoparticle composite material is subjected to scanning electron microscope observation, and the results are shown in figure 2 . From figure 2 The morphology of the prepared graphene oxide and titanium dioxide nanoparticle composite sample can be seen. It can be seen that the titanium dioxide nanoparticles are mainly dispersed to the edges and folds of graphene oxide, and the size of graphene oxide is about 500nm. According to the test sampling and testing process of step 7) in Example 1, the photocatalytic efficiency of the composite material of graphene oxide and titanium dioxide nanoparticles has been improved by 60% compared with P25, and the dye can be degraded even under the condition of no light completely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com