A kind of preparation method of 2,2-dimethylcyanoacetamide

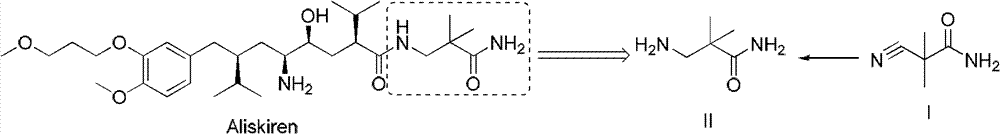

A technology of dimethyl cyanoacetamide and cyanoacetamide, which is applied in the preparation of the side chain intermediate of antihypertensive drug Aliskiren and the field of preparation 2, which can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

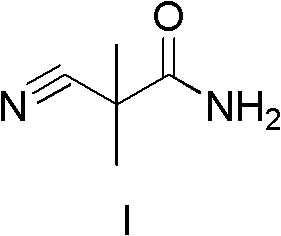

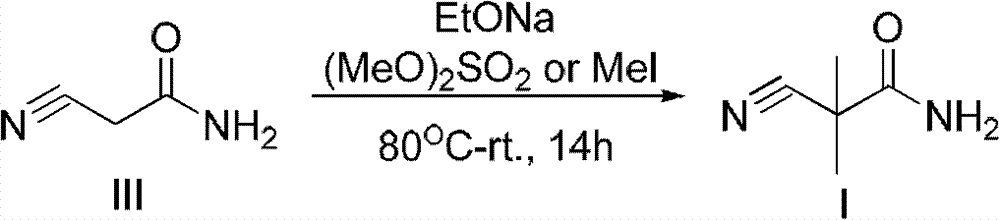

[0027] The preparation method of 2,2-dimethylcyanoacetamide provided by the invention comprises steps:

[0028] In the first step, cyanoacetamide and methylating reagent are simultaneously added to the tetrahydrofuran solution of sodium hydrogen, and cooled to minus 25 degrees Celsius to room temperature (preferably minus 25 degrees Celsius to 5 degrees Celsius) with an ice bath;

[0029] In the second step, after adding the materials, the temperature is raised to room temperature to 45 degrees Celsius, and the reaction is performed for 15 minutes to 2 hours;

[0030] The third step is quenching with saturated ammonium chloride, then the solvent is evaporated, and then water is added to form a saturated solution;

[0031] The fourth step is to extract 5-15 times with dichloromethane, dry, filter, and evaporate to dryness;

[0032] In the fifth step, crystallize with ethyl acetate:n-hexane=1:1 to obtain 2,2-dimethylcyanoacetamide.

[0033] Another preparation method of 2,2-di...

Embodiment 1

[0051] In a solution of sodium hydrogen (5.75g, 2.3eq) in tetrahydrofuran, cyanoacetamide (5.23g, 1eq) and dimethyl sulfate (17.35g, 2.2eq) were added simultaneously, and cooled to about 5 degrees Celsius with an ice bath, After adding the material, raise the temperature to about 45 degrees Celsius, react for 15 minutes to 30 minutes, quench with 40ml of saturated ammonium chloride, then evaporate the solvent, add water to make a saturated solution, and extract 10 times with 50ml of dichloromethane. Dry, filter, evaporate to dryness, and repeat crystallization with ethyl acetate:n-hexane=1:1 to obtain product I (5.95g), yield 85%, melting point 105-106°C. ESI-MS (M+NH 4 + ) = 130.1.

Embodiment 2

[0053] In tetrahydrofuran solution of sodium hydrogen (5.75g, 2.3eq), add cyanoacetamide (5.23g, 1eq) and dimethyl sulfate (17.35g, 2.2eq) at the same time, and cool to about -25 degrees Celsius with an ice bath , after adding the material, warm up to room temperature, react for 2 hours, quench with 40ml of saturated ammonium chloride, then evaporate the solvent, then add water to form a saturated solution, extract 10 times with 50ml of dichloromethane, dry, filter, After evaporation to dryness, repeated crystallization with ethyl acetate: n-hexane = 1:1, the product I (5.60 g) was obtained with a yield of 80% and a melting point of 105-106°C. ESI-MS (M+NH 4 + ) = 130.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com