Method of extracting cynomorium songaricum polysaccharide through enzyme treatment and preparation of cynomorium songaricum polysaccharide antineoplastic agents

A technology for treating Cynomorium polysaccharide and enzyme is applied in the preparation of Cynomorium polysaccharide anti-tumor preparations, and the preparation field of Cynomorium polysaccharide can solve the problems of high operation cost, long extraction time and high extraction cost, and achieves improving immunity and improving The effect of low extraction rate and extraction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

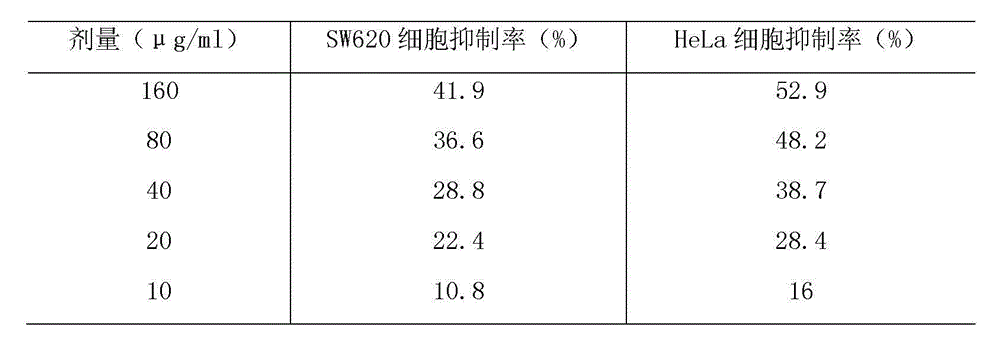

[0021] Experimental example 1 Experiment of the inhibitory effect of Cynomorium polysaccharide on tumor cells

[0022] Test cells: colon cancer SW620 cells and cervical cancer HeLa cells

[0023] Experimental method: Take tumor cells in the logarithmic growth phase, digest them with trypsin, wash with Hank’s solution, and adjust the cells to 1×10 with RPMI1640 culture medium containing 10% calf serum. 5 / ml. Add 100 μl of the above-mentioned cell suspension to each well of the 96-well culture plate, in 5% CO 2 After culturing in an incubator at 37°C and saturated humidity for 24 hours, 100 μl of Cynomorium polysaccharide of different concentrations prepared with 10% calf serum RPMI1640 culture solution was added to each well of the experimental group, and 10% calf serum RPMI1640 was added to each well of the control group. 100 μl of culture solution, 6 replicate wells for each concentration, cultured for 72 hours. 4 hours before the termination of the experiment, take the c...

Embodiment 1

[0031] 1) Crush the dried Cynomorium and pass through a 60-mesh sieve, take 1kg of Cynomorium dry powder and put it into an extraction tank with stirring, add 15kg of distilled water, then raise the temperature to 75°C and let it stand for 40 minutes.

[0032] 2) Enzymolysis: After soaking, cool down to 35°C, add cellulase, hemicellulase, pectinase, and neutral protease, turn on the stirring device, adjust the speed to 30 rpm, and keep stirring at 35°C for 2 hours , the addition of cellulase is 3% of the mass of Cynomorium powder, the addition of hemicellulase is 5‰ of the mass of Cynomorium powder, the addition of pectinase is 1% of the mass of Cynomorium powder, and the addition of neutral protease is the mass of Cynomorium powder Quality 5‰.

[0033] 3) Enzyme inactivation and high-speed stirring: heat the soaking solution to 85°C, adjust the speed to 200 rpm, and keep it warm for 10 minutes.

[0034] 4) Concentration and alcohol precipitation: After step 4), the stirring ...

Embodiment 2

[0037] The steps are the same as in Example 1, except that cellulase and papain are added after soaking, the amount of cellulase added is 8% of the mass of Cynomorium powder, and the amount of papain added is 8% of the mass of Cynomorium powder. Obtained Cynomorium polysaccharide 71.6g, Cynomorium polysaccharide content is 84.6%. Take Cynomorium polysaccharide dry powder 200g and dissolve in 800ml purified water, add appropriate amount of correctives and preservatives according to drug quality requirements, shake well, bottle according to 10ml specification, and make Cynomorium polysaccharide anti-tumor oral liquid preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com