Preparation of cellulose grafted acrylate copolymer and application of copolymer as adsorbent

A cellulose grafting and copolymer technology, applied in the polymer field, can solve problems such as pollution, plant straw burning, waste of resources and the environment, and achieve the effects of high decolorization rate, good selectivity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

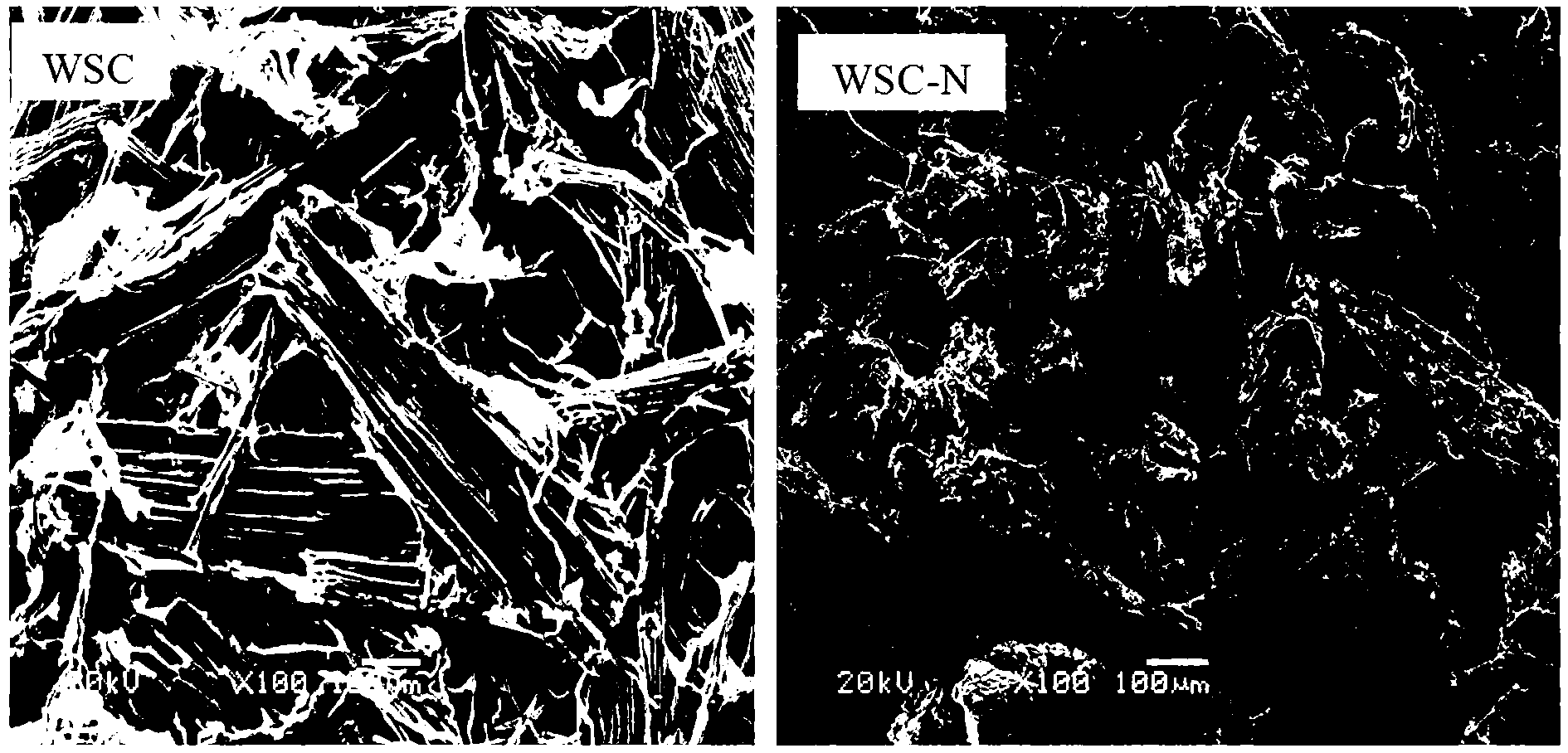

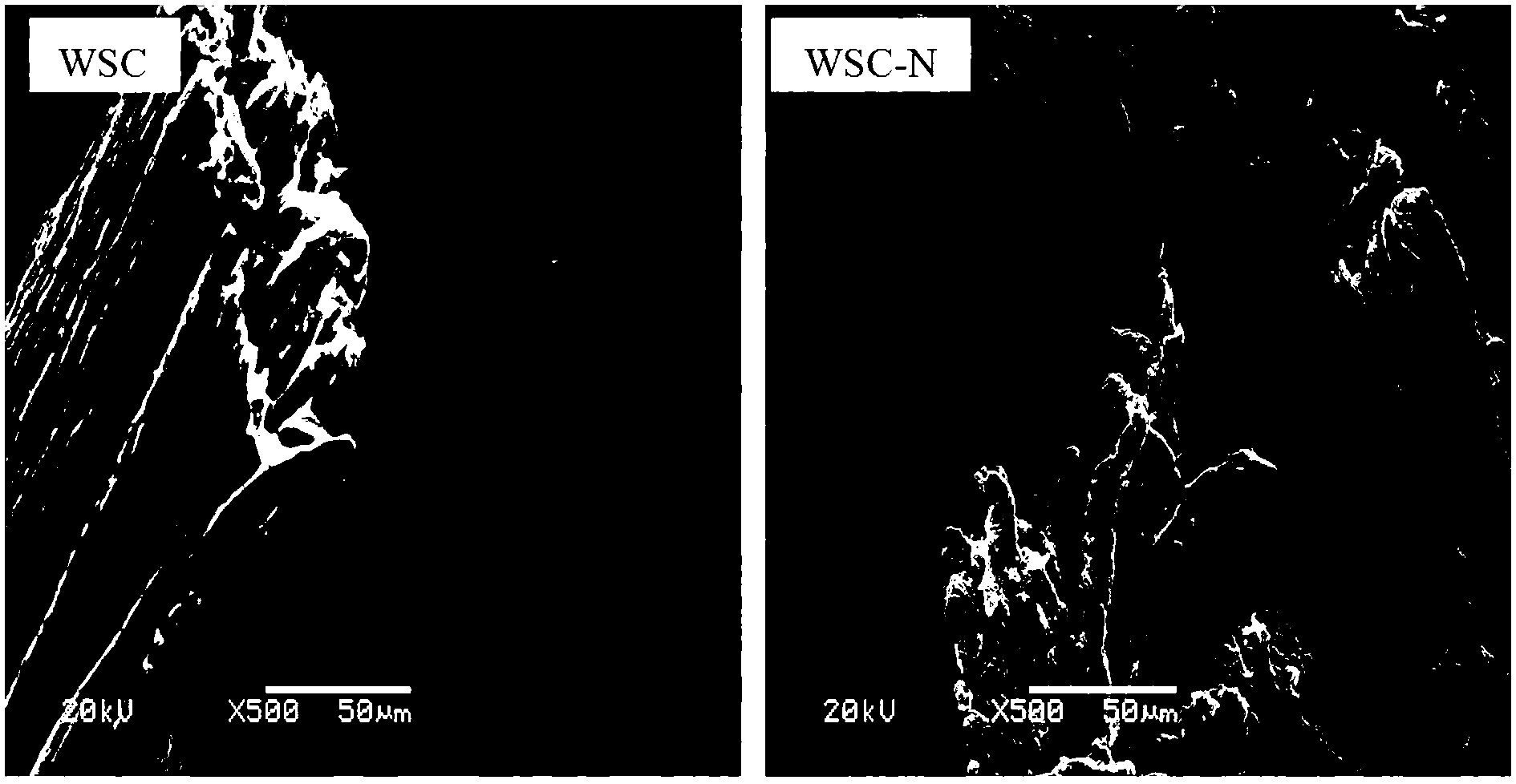

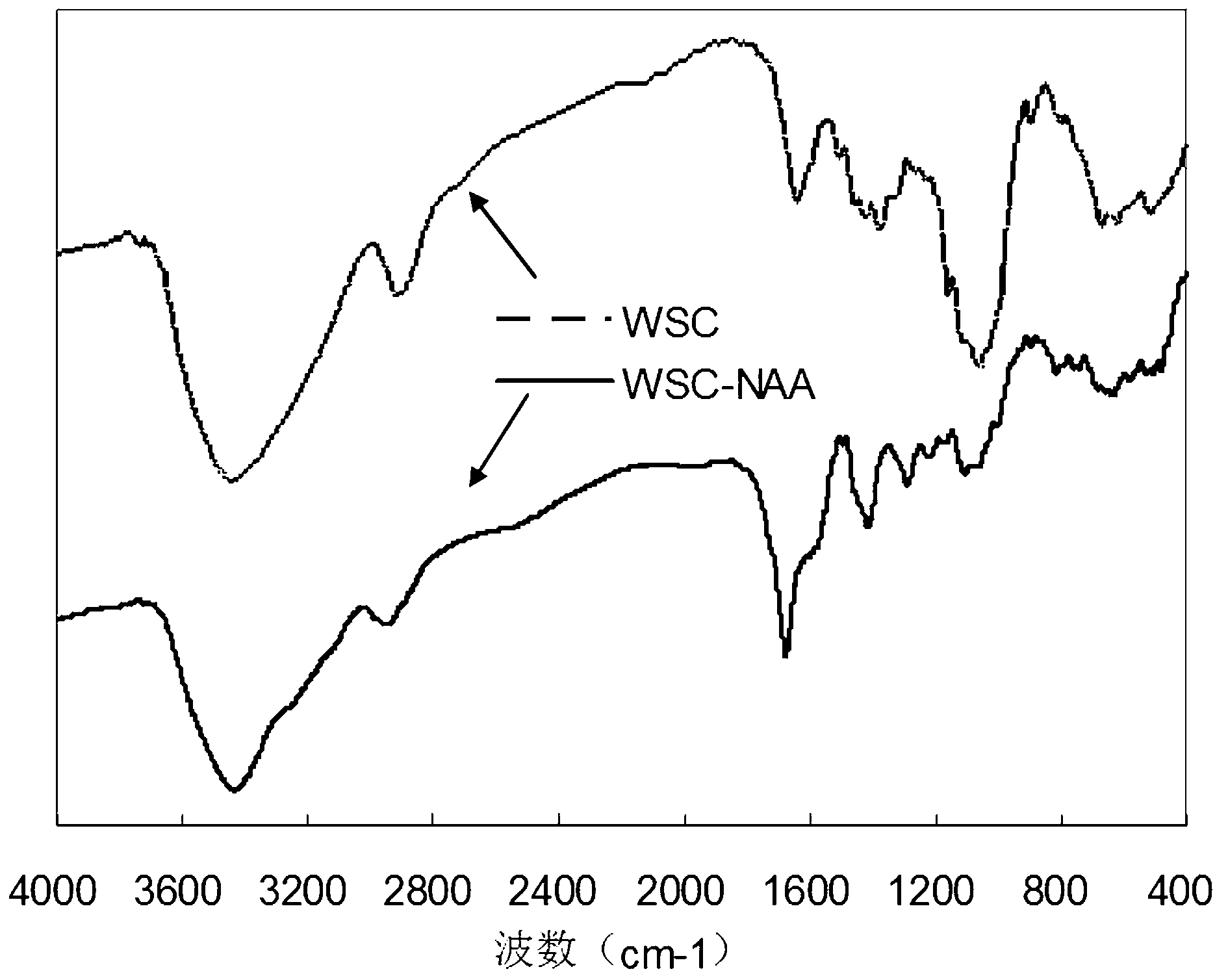

[0041] 1. Preparation of Wheat Straw Cellulose Adsorbent

[0042] Add 1 g of wheat straw cellulose into 5 mL of distilled water and stir well, add 0.016 g of azobisisobutyronitrile previously dispersed in water, control the temperature at 50 °C, and then add 0.008 g of cross-linking agent N,N -Methylenebisacrylamide, stir to dissolve, and at the same time add 0.1 g of sodium acrylate with a neutralization degree of 50%, N -Vinylpyrrolidone 0.5 g, reacted at constant temperature for 2 h; when the rod climbing phenomenon occurs, the reaction is over, cooled to room temperature, and the polymer product is obtained; then the polymer product is soaked and settled in absolute ethanol for 10 min, filtered, and washed twice with distilled water. , suction filtration, vacuum drying, and grinding into powder to obtain a wheat straw cellulose copolymer adsorbent.

[0043] 2. Determination of adsorption performance

[0044] (1) Adsorption test on simulated wastewater containing methylen...

Embodiment 2

[0047] 1. Preparation of Wheat Straw Cellulose Adsorbent

[0048] Add 2 g of wheat straw cellulose into 10 mL of distilled water and stir well, add 0.05 g of initiator azobisisobutyronitrile dispersed in water in advance, control the temperature at 60 °C, and then add 0.005 g of cross-linking agent N,N -Methylenebisacrylamide, stir to dissolve, and at the same time add 1 g of sodium acrylate with 50% neutralization degree dropwise, N -Vinylpyrrolidone 2 g), reacted at a constant temperature for 3 h, until the phenomenon of climbing rods appeared, the reaction was over, cooled to room temperature, and the polymer product was obtained; then the polymer product was soaked and settled in absolute ethanol for 30 min, filtered, and repeatedly washed with distilled water for 3 time, suction filtration, vacuum drying, and grinding into powder to obtain a wheat straw cellulose copolymer adsorbent.

[0049] 2. Determination of adsorption performance

[0050] (1) Adsorption test on sim...

Embodiment 3

[0053] 1. Preparation of Wheat Straw Cellulose Adsorbent

[0054] Add 3 g of wheat straw cellulose into 20 mL of distilled water and stir well, add 0.24 g of initiator azobisisobutyronitrile dispersed in water in advance, control the temperature at 70 °C, and then add 0.06 g of cross-linking agent N,N -Methylenebisacrylamide, stir to dissolve, and at the same time add 3 g of sodium acrylate with a neutralization degree of 50%, N - 6 g of vinylpyrrolidone, reacted at constant temperature for 4 hours, until the phenomenon of climbing rods appeared, the reaction was over, cooled to room temperature to obtain a polymer product; then the polymer product was soaked and settled in absolute ethanol for 60 min, filtered, and washed with distilled water for 4 times. , suction filtration, vacuum drying, and grinding into powder to obtain a wheat straw cellulose copolymer adsorbent.

[0055] 2. Determination of adsorption performance

[0056] (1) Adsorption test on simulated wastewater ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com