Lubricant composition containing ionic liquid and manufacture method thereof

A technology of lubricant composition and ionic liquid, which is applied in the direction of lubricating composition, additives, petroleum industry, etc., can solve the problems of expensive cost, complex synthesis steps, poor compatibility, etc., and achieve low cost, simple preparation process, tribological The effect of excellent performance

Active Publication Date: 2014-06-04

LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The ionic liquids reported in the literature as lubricating oil additives are generally ionic liquids of quaternary ammonium, quaternary phosphorus, pyridine, and imidazole cations. These ionic liquids need to be prepared through complex steps such as alkylation, ion exchange, separation, and purification. , their complex synthesis steps, high cost, poor compatibility with base oils, and corrosion to substrates limit their application in the field of tribology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

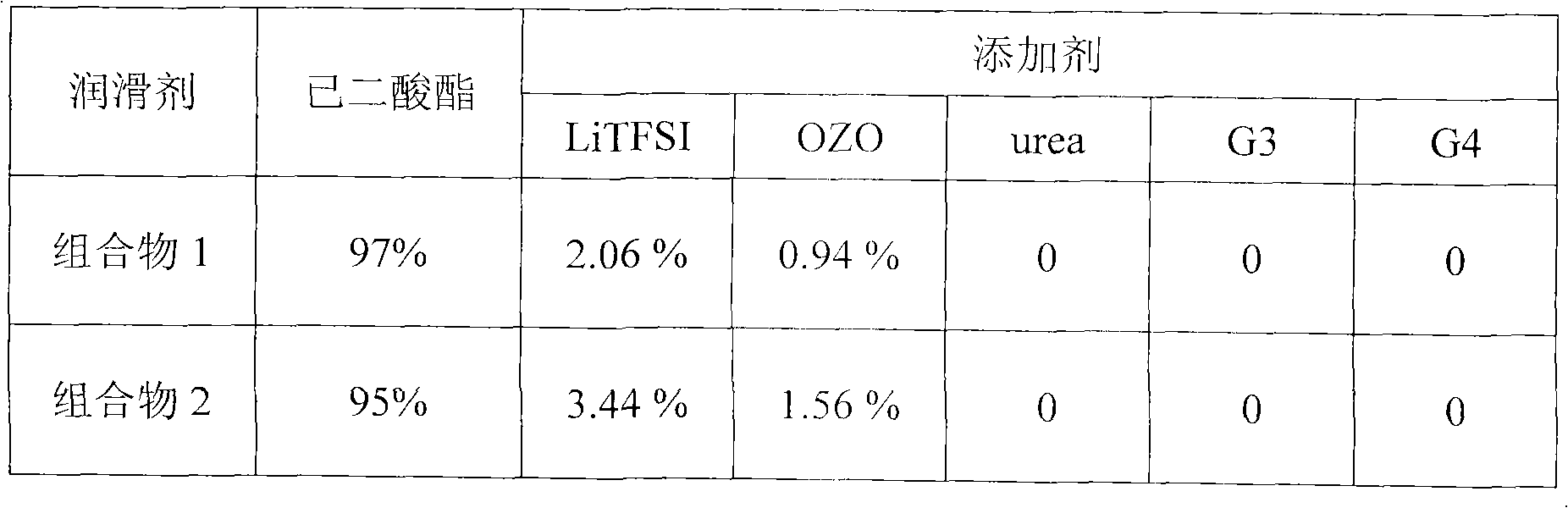

[0024] Example 1: Add 0.687% LiTFSI and 0.313% OZO into 99% base oil adipate, stir and dissolve to form a lubricant containing 1% [Li(OZO)]TFSI ionic liquid agent composition.

Embodiment 2

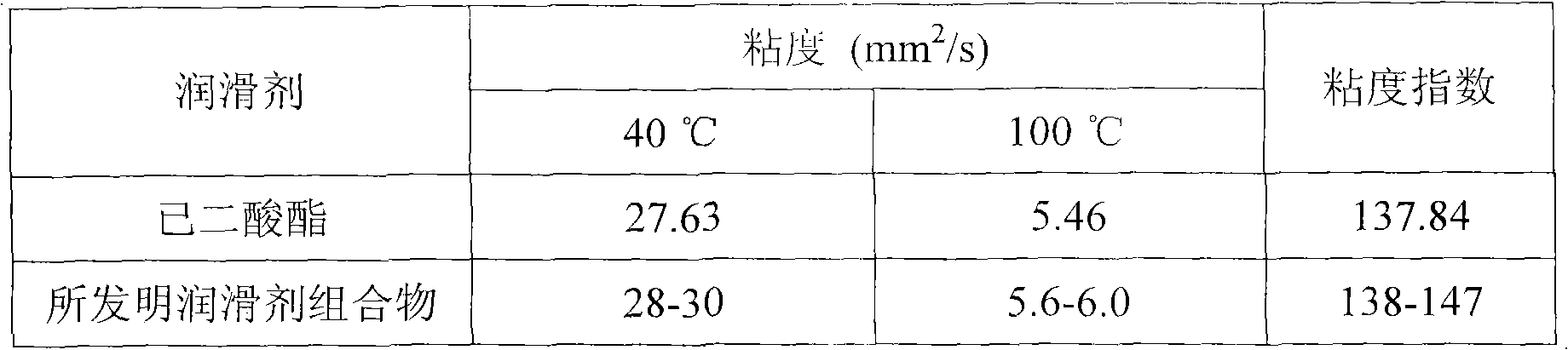

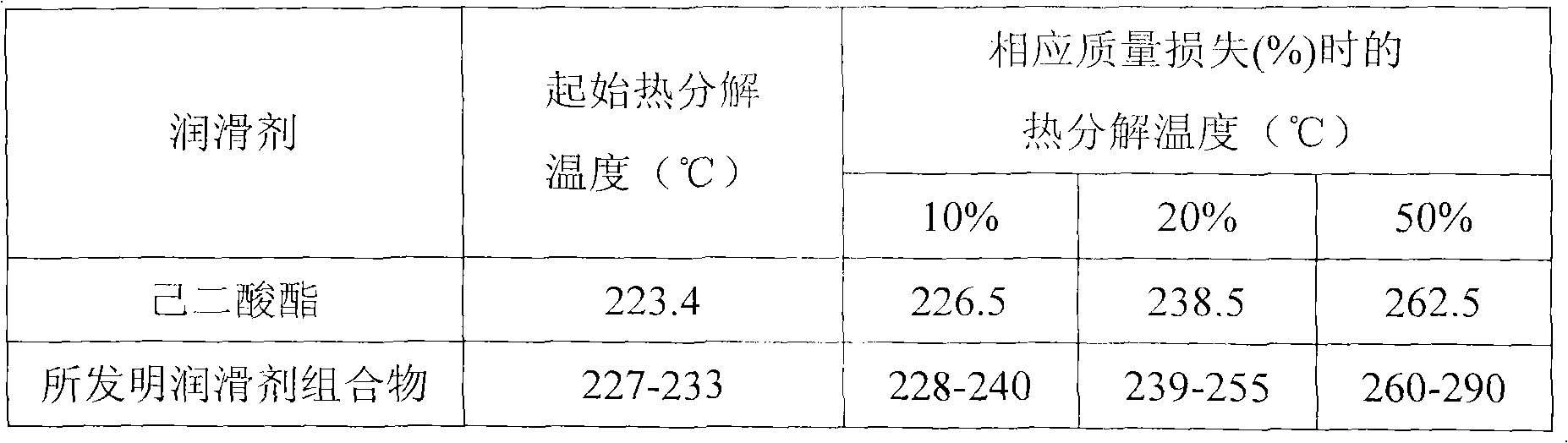

[0025] Embodiment 2: In the same preparation method as in Embodiment 1, the following lubricant compositions were prepared.

[0026]

[0027]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersion coefficient | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a lubricant composition containing ionic liquid and a manufacture method of the lubricant composition. The composition comprises base oil and ionic liquid, wherein the mass fraction of the base oil is 99%-95% and the mass fraction of the ionic liquid is 1%-5%. The base oil is adipate and the ionic liquid is a mixture compounded by one or two selected from bistrifluoromethanesulfonimide lithium and 2-Oxazolidone or urea or triethyle ne glycol dimethyl ether or tetraethylene glycol dimethyl ether. The ionic liquid and the lubricant composition can be synchronously compounded. The ionic liquid is simple in process, low in raw material cost and suitable for industrialization and has good chemical stability and thermal stability. The lubricant composition has good anti-wear performance and abrasion resistance to steel or a steel friction pair.

Description

technical field [0001] The invention relates to a lubricant composition containing an ionic liquid and a preparation method thereof. The preparation process of the composition is simple, and the lubricant used as a steel / steel friction pair has excellent friction-reducing and anti-wear properties. Background technique [0002] Since the 1940s, ionic liquids have become one of the frontiers and research hotspots of contemporary chemical science with their own advantages. It has the advantages that many molecular solvents do not have, such as non-flammable and explosive, low melting point, low volatility, good oxidation resistance and high thermal stability (Deng Youquan. Ionic liquid - properties, preparation and application [M]. Beijing : China Petrochemical Press, 2006.11), which makes it widely concerned as an ideal green reagent in the fields of organic catalysis and synthesis, electrochemistry, photochemistry and separation processes. At the same time, these characteris...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10M141/08C10N30/06

Inventor 凡明锦宋增红梁永民周峰

Owner LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com