Combined modified-asphalt root penetration resistance waterproof roll and preparation method thereof

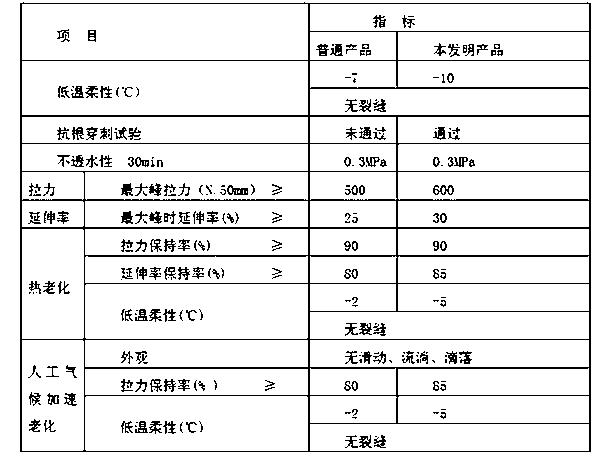

A technology for modifying asphalt and waterproofing membranes, which is applied to asphalt layered products, chemical instruments and methods, and roofing using flexible materials, etc. Weakness, short service life and other problems, to achieve the effect of excellent root puncture resistance, improved product strength, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1, this combined modified asphalt root puncture-resistant waterproof membrane is composed of a surface layer, an upper waterproof layer, a base layer, a lower waterproof layer and a bottom layer;

[0044] The material composition and weight percentage ratio of the upper waterproof layer and the lower waterproof layer are as follows;

[0045] Bitumen 42%;

[0046] Engine oil 15%;

[0047] Polyolefin 8%;

[0048] SBS 8%

[0049] Wollastonite powder 12%;

[0050] Silicon carbide whisker powder 2%

[0051] Silicon nitride whisker powder 2%

[0052] Calcium Carbonate Whiskers Powder 4%

[0053] Nano Zinc Oxide 4.5%;

[0054] Chemical root inhibitor 2.5%.

[0055]

Embodiment 2

[0056] Example 2, this combined modified asphalt root puncture-resistant waterproof membrane is composed of a surface layer, an upper waterproof layer, a base layer, a lower waterproof layer and a bottom layer;

[0057] The material composition and weight percentage ratio of the upper waterproof layer and the lower waterproof layer are as follows;

[0058] Bitumen 31%;

[0059] Engine oil 20%;

[0060] Polyolefin 12%;

[0061] SBS 3%

[0062] Wollastonite powder 25%;

[0063] Silicon carbide whisker powder 1%

[0064] Silicon nitride whisker powder 1%

[0065] Calcium Carbonate Whiskers Powder 1%

[0066] Nano Zinc Oxide 5.5%;

[0067] Chemical root inhibitor 0.5%.

[0068]

Embodiment 3

[0069]Example 3, this combined modified asphalt root puncture-resistant waterproof membrane is composed of a surface layer, an upper waterproof layer, a base layer, a lower waterproof layer and a bottom layer;

[0070] The material composition and weight percentage ratio of the upper waterproof layer and the lower waterproof layer are as follows;

[0071] Bitumen 40%;

[0072] Engine oil 15%;

[0073] Polyolefin 2%;

[0074] SBS 13%

[0075] Wollastonite powder 10%;

[0076] Silicon carbide whisker powder 5%

[0077] Silicon nitride whisker powder 5%

[0078] Calcium Carbonate Whiskers Powder 3%

[0079] Nano Zinc Oxide 6%;

[0080] Chemical root inhibitor 1%.

[0081]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com