Composite forward osmosis membrane and preparation method thereof

A forward osmosis membrane and casting liquid technology, which is applied in the field of preparation of polymer membranes for water treatment, can solve the problem that the flux of the forward osmosis membrane is not greatly improved, and can reduce the phenomenon of internal concentration polarization and improve the water flow. Quantity, good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

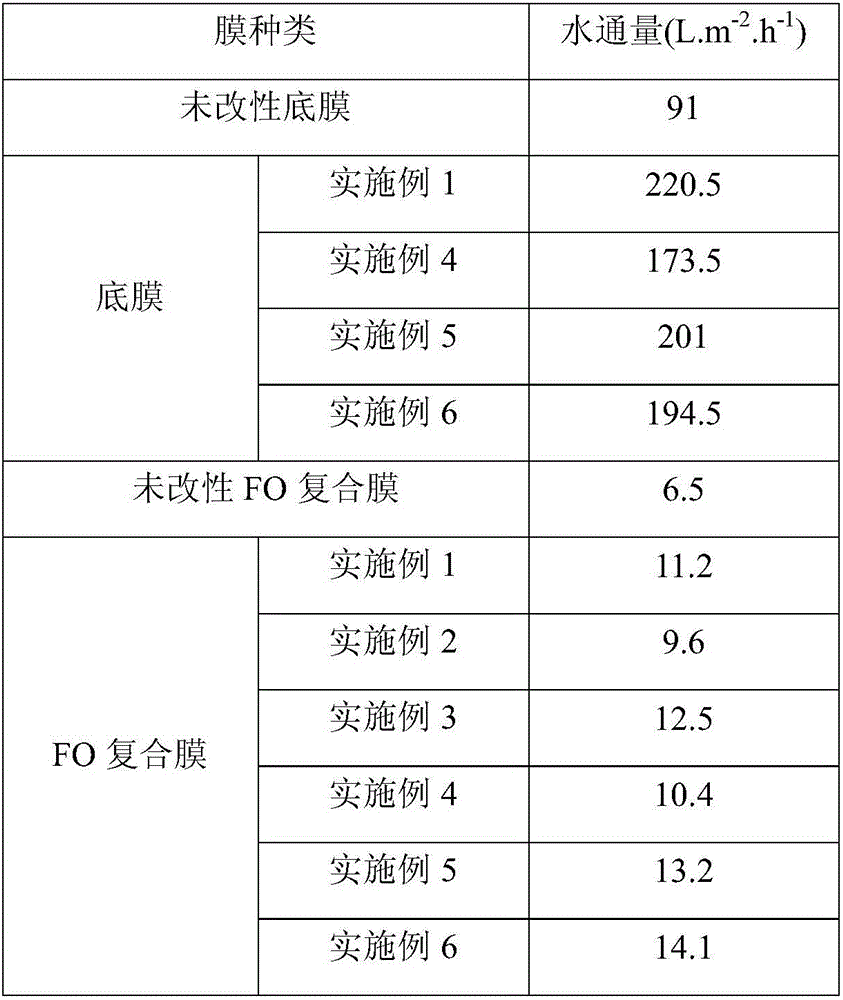

Examples

preparation example Construction

[0049] Preparation method of composite forward osmosis membrane

[0050] The preparation method of composite forward osmosis membrane provided by the invention comprises the following steps:

[0051] (1) coating the casting solution on the low-density non-woven fabric layer, and phase inverting in the gel bath to obtain a porous support layer;

[0052] (2) On the porous support layer, the polyvalent amine aqueous solution reacts with the polyvalent acid chloride organic solution to form the ultra-thin separation layer, thereby obtaining the composite forward osmosis membrane.

[0053] The casting solution is prepared by dissolving a polymer in an organic solvent, wherein the polymer is polysulfone, polyethersulfone, sulfonated polysulfone, polysulfone amide, polyarylether sulfone ketone, polyarylether nitrile Ketone, copolyethersulfone, polyvinylidene fluoride, polyacrylonitrile, or cellulose acetate and their mixtures, the solvent is N,N-dimethylformamide, N,N-dimethylacetam...

Embodiment 1

[0070] Weigh 16g of polysulfone, dissolve it in 84g of a mixed solvent composed of N,N-dimethylacetamide and PEG-400, and prepare a bottom membrane casting solution with a polymer concentration of 18%. Add 2g of hydrophilic nano-particle montmorillonite to the prepared bottom film casting solution to form a bottom film casting solution with a montmorillonite concentration of 2%, and disperse in ultrasonic for 30 minutes to obtain a bottom film casting film with uniformly dispersed nanoparticles liquid. The bottom membrane casting liquid is used on the low-density non-woven support layer, the scraper is scraped with a certain thickness, and the membrane is gelled in deionized water in a gel bath to form a polysulfone ultrafiltration bottom membrane.

[0071] In the organic phase solvent n-hexane of the interfacial polymerization reaction, add hydrophilic nanoparticles NaA type molecular sieve as an additive of the organic phase, and make a solution containing 0.4% of nanopartic...

Embodiment 2

[0073] Take by weighing 2.5g o-phenylenediamine and be mixed with 2.5% o-phenylenediamine aqueous solution, add 0.2g nano-particle carbon nanotube and be mixed with the aqueous phase solution that contains nano-particle concentration and be 0.2%, and 0.15% trimesoyl chloride Organic phase solution reaction, carry out interfacial polymerization on the prepared polysulfone ultrafiltration bottom membrane (prepared by phase inversion method in Example 1) to generate an active ultra-thin layer, which is heat-treated in a constant temperature heating box at 100-110°C to make The prepared active thin layer is stable, and the treated composite forward osmosis membrane is washed with deionized water to remove unreacted solvent to obtain a composite forward osmosis membrane, which is stored in deionized water for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com