Oxygen sensor electrode, concentration-difference type oxygen sensor with oxygen sensor electrode, and preparation method for same

An oxygen sensor and electrode technology, which is applied in the field of automotive sensors, can solve the problems of poor bonding between electrodes and zirconia solid electrolytes, reduced electrode overburning catalytic performance, and low catalytic performance of oxygen sensor electrodes, and achieves good current conductivity and platinum content. The effect of high, response rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

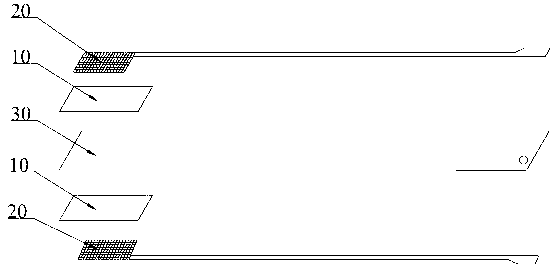

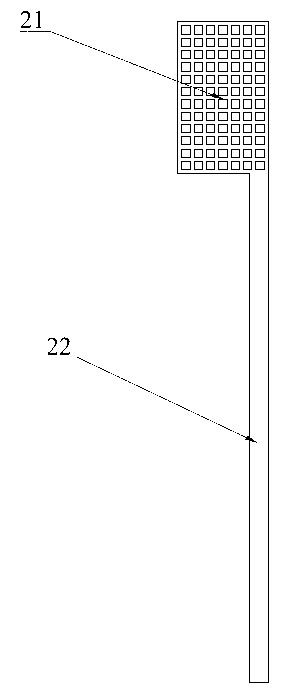

[0033] The present invention provides a preparation method of the oxygen sensor with the electrode structure of the present invention by taking the concentration difference type chip oxygen sensor as an example, and the method includes the following steps.

[0034] (1) Prepare the green body of the heating unit, the reference gas substrate and the zirconia solid electrolyte substrate.

[0035] First, take a heater substrate, apply insulating layer slurry, heating electrode slurry, and insulating layer slurry on the heater substrate accordingly, and dry to obtain a heating unit green body;

[0036] Prepare a reference gas substrate green body, the reference gas substrate green body is provided with a reference gas channel, and the reference gas channel can be formed by die punching, laser cutting and other processes;

[0037] Prepare the zirconia solid electrolyte matrix green body of the oxygen measuring unit;

[0038] In the preparation method of the green body of the oxygen...

Embodiment 1

[0051] (1) Prepare the green body of the heating unit of the chip oxygen sensor, the reference gas substrate and the zirconia solid electrolyte substrate.

[0052] (2) Prepare the green body of the oxygen measuring unit.

[0053] a. Electrode slurry organic system preparation: Take 10g of ethyl cellulose, stir it into 85g of terpineol, stir in 80°C water bath until completely dissolved. Cool the terpineol solution of ethyl cellulose above to room temperature, add 2g of dispersant, 2g of leveling agent, and 1g of defoamer, and stir until completely miscible.

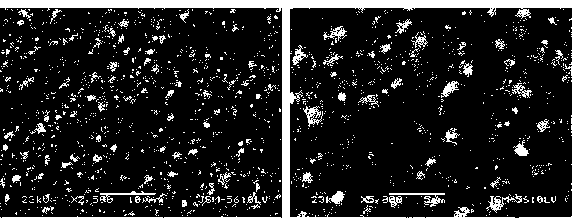

[0054] b. Catalytic reaction layer slurry preparation: take 7.5g of high-purity platinum powder, 10.5g of aluminum oxide powder, 1g each of cerium oxide powder, rhodium oxide powder, and lanthanum oxide powder, and 80g of zirconia powder until uniformly mixed to obtain catalytic reaction layer powder System: Take 50 g of catalytic reaction layer powder, stir and add 50 g of the organic system prepared in step a, three-ro...

Embodiment 2

[0059] (1) The heating unit of the chip oxygen sensor, the reference gas substrate and the green body of the zirconia solid electrolyte substrate prepared in step (1) of Example 1 are used.

[0060] (2) Prepare the green body of the oxygen measuring unit.

[0061] a. Organic system preparation: The organic system was prepared by adopting the scheme of step a in Example 1.

[0062] b. Catalytic reaction layer slurry preparation: take 5g of high-purity platinum powder, 5g of aluminum oxide powder, 2g of cerium oxide powder, 2g of rhodium oxide powder, 1g of lanthanum oxide powder, and 85g of zirconia powder until uniformly mixed to obtain catalytic reaction layer powder system. Take 30 g of catalytic reaction layer powder, stir and add 70 g of the organic system prepared in step a, three-roll grinding for 2 hours, and use a scraper fineness meter to check that the particle size of the slurry is less than 1 μm, and the catalytic reaction layer slurry is obtained.

[0063] c. Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com