Ce-doped Bi4-xCexTi3O12 electro-resistance changing film and preparation method of resistance changing capacitor

A technology of resistive thin film and thin film, which is applied in the direction of electrical components, can solve problems such as performance gaps, achieve the effects of improving quality and performance, precise components, and increasing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

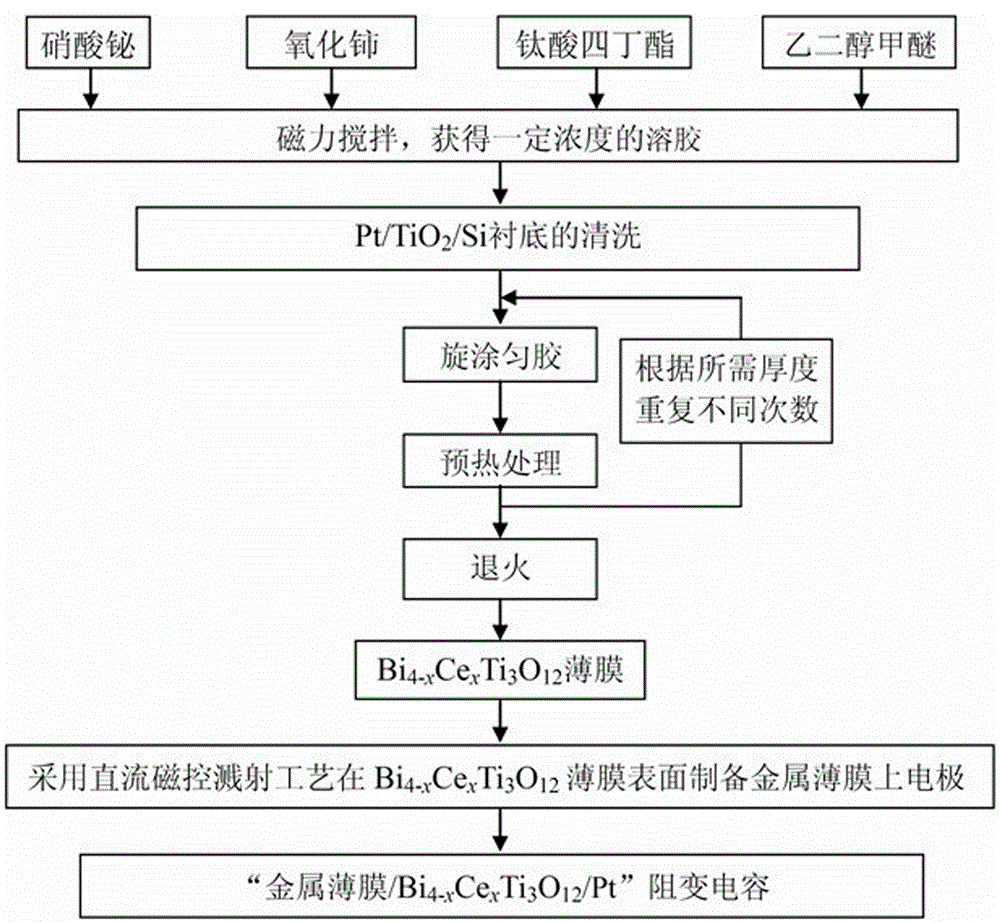

[0045] A Ce-doped Bi 4-x Ce x Ti 3 o 12 The preparation method of the electro-resistive variable film and the resistive variable capacitance thereof comprises the following steps:

[0046] (1) With Pt / TiO 2 / Si as the substrate, surface treatment and cleaning of the substrate:

[0047] ① Soak in sodium hydroxide solution for 5 hours to remove the remaining attachments on the surface;

[0048] ② Ultrasonic cleaning with acetone for 8 minutes to remove organic matter on the substrate surface;

[0049] ③ Ultrasonic cleaning with ethanol for 10 minutes to remove hydrocarbons on the glass surface;

[0050] ④ Finally, ultrasonic cleaning with deionized water for 10 minutes to remove residual ethanol.

[0051] (2) Prepare Bi with the following raw materials 3.75 Ce 0.25 Ti 3 o 12 Sol:

[0052] Bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) 675.70 grams

[0053] Cerium oxide (CeO 2 ) 15.06 grams

[0054] Tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ) 357.38 grams

[0055] Ethylen...

Embodiment 2

[0069] A Ce-doped Bi 4-x Ce x Ti 3 o 12 The preparation method of the electro-resistive variable film and the resistive variable capacitance thereof comprises the following steps:

[0070] (1) With Pt / TiO 2 / Si as the substrate, surface treatment and cleaning of the substrate:

[0071] ① Soak in sodium hydroxide solution for 6 hours to remove the remaining attachments on the surface;

[0072] ② Ultrasonic cleaning with acetone for 8 minutes to remove organic matter on the substrate surface;

[0073] ③ Ultrasonic cleaning with ethanol for 12 minutes to remove hydrocarbons on the glass surface;

[0074] ④ Finally, ultrasonic cleaning with deionized water for 10 minutes to remove residual ethanol.

[0075] (2) Prepare Bi with the following raw materials 3.70 Ce 0.3 Ti 3 o 12 Sol:

[0076] Bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) 570.44 grams

[0077] Cerium oxide (CeO 2 ) 15.49 grams

[0078] Tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ) 306.32 grams

[0079] Ethylene g...

Embodiment 3

[0090] A Ce-doped Bi 4-x Ce x Ti 3 o 12 The preparation method of the electro-resistive variable film and the resistive variable capacitance thereof comprises the following steps:

[0091] (1) With Pt / TiO 2 / Si as the substrate, surface treatment and cleaning of the substrate:

[0092] ① Soak in sodium hydroxide solution for 6 hours to remove the remaining attachments on the surface;

[0093] ② Ultrasonic cleaning with acetone for 10 minutes to remove organic matter on the substrate surface;

[0094] ③ Ultrasonic cleaning with ethanol for 12 minutes to remove hydrocarbons on the glass surface;

[0095] ④ Finally, ultrasonic cleaning with deionized water for 10 minutes to remove residual ethanol.

[0096] (2) Prepare Bi with the following raw materials 3.80 Ce 0.2 Ti 3 o 12 Sol:

[0097] Bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) 781.93 grams

[0098] Cerium oxide (CeO 2 ) 13.77 grams

[0099] Tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ) 408.43 grams

[0100] Ethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com