Novel high-efficiency solid compound enzyme for beer

A compound enzyme and high-efficiency technology, applied in the brewing, enzymes, hydrolase and other directions of beer, can solve the problems of insufficient catalysis of external enzymes, insufficient enzyme activity, and few endogenous enzymes, so as to improve abiotic stability and promote yeast. Effects of proliferation, component science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

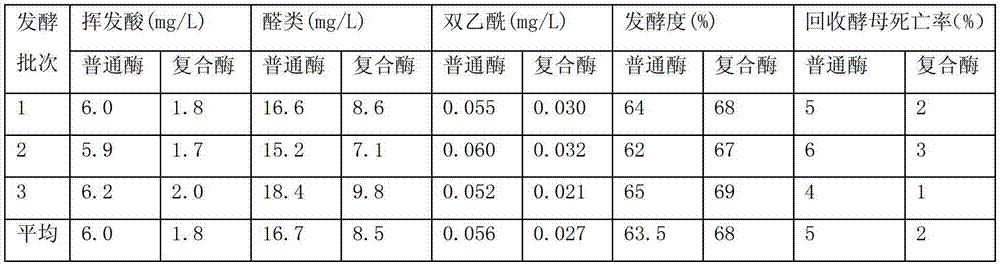

Examples

Embodiment 1

[0050] First, accurately weigh 35 parts of solid powder enzyme preparation amylase, 30 parts of protease, 30 parts of hemicellulase, 15 parts of esterase, 15 parts of oxidase, and mix evenly to obtain a mixed enzyme preparation; then accurately weigh 40 parts of zinc chloride , 20 parts of calcium chloride, 20 parts of sodium sulfate, and 10 parts of magnesium chloride were uniformly and quickly mixed to obtain an activator; finally, the mixed enzyme preparation and activator were quickly and uniformly mixed according to a mass ratio of 5:1, and vacuum-packed to obtain a new type of high-efficiency beer solid compound enzyme.

[0051] (1) How to use:

[0052] In the saccharification stage, the beer compound enzyme preparation of the present invention is added to the saccharification pot:

[0053] First, accurately weigh the beer compound enzyme, add 5 times of 50°C saccharification water into the stainless steel container, stir and dissolve for 5 minutes, add the mash pot 5-10...

Embodiment 2

[0062] First, accurately weigh 25 parts of solid powder enzyme preparation amylase, 20 parts of protease, 20 parts of hemicellulase, 12 parts of esterase, 12 parts of oxidase, and mix evenly to obtain a mixed enzyme preparation; then accurately weigh 35 parts of zinc chloride , 15 parts of calcium chloride, 15 parts of sodium sulfate, and 8 parts of magnesium chloride are evenly mixed to obtain an activator; finally, the mixed enzyme preparation and the activator are quickly and uniformly mixed according to the mass ratio of 2:1, and vacuum-packed to obtain a new type of high-efficiency beer solid compound enzyme.

Embodiment 3

[0064] First, accurately weigh 15 parts of solid powder enzyme preparation amylase, 15 parts of protease, 15 parts of hemicellulase, 10 parts of esterase, 10 parts of oxidase, and mix evenly to obtain a mixed enzyme preparation; then accurately weigh 30 parts of zinc chloride , 10 parts of calcium chloride, 10 parts of sodium sulfate, and 5 parts of magnesium chloride are evenly mixed to obtain an activator; finally, the mixed enzyme preparation and the activator are quickly and uniformly mixed according to a mass ratio of 1:1, and vacuum-packed to obtain a new type of high-efficiency beer solid compound enzyme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com