Preparation method of metal silver ordered porous array membrane

A porous array and metal silver technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of polystyrene microspheres easy to fall off, product quality is difficult to guarantee, template defects increase, etc., to achieve Low cost, strong adhesion, saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The concrete steps of preparation are:

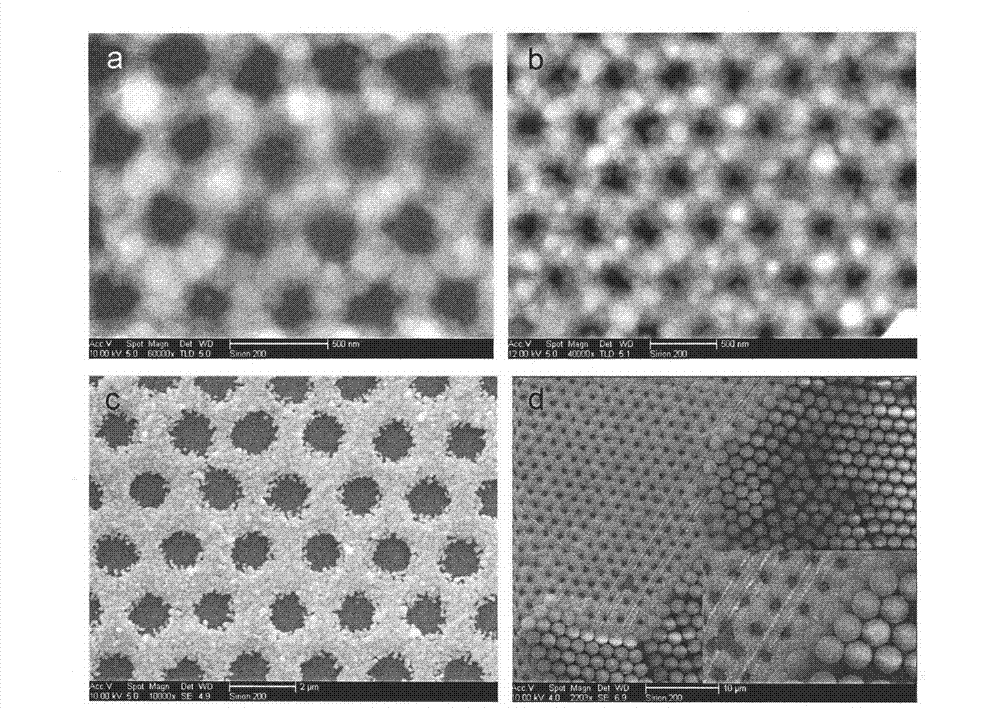

[0021] In step 1, a solution of polystyrene spheres with a concentration of 2.3 wt % and a diameter of 500 nm is coated on a substrate; wherein the substrate is a silicon wafer, and the coating is performed by spin coating. Then place the substrate with polystyrene balls on it in a plasma cleaning machine and use argon plasma to etch for 3 minutes; wherein, the etching power is 18W, and the polystyrene balls with loose orderly arrangement on it are obtained. Substrate for vinyl sphere templates.

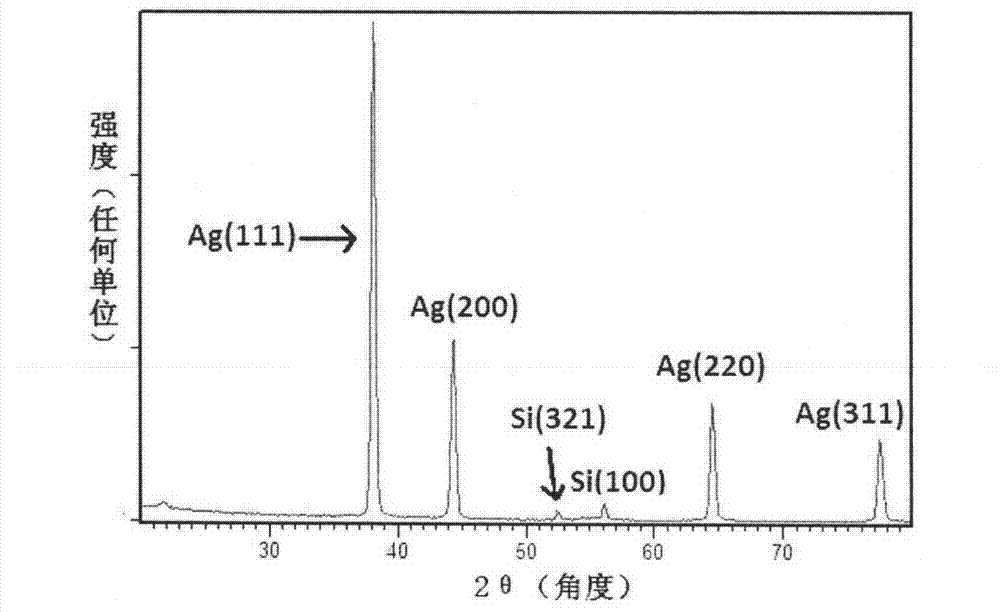

[0022] In step 2, silver nitrate, hydrofluoric acid with a concentration of 38wt% and water are mixed according to the weight ratio of 0.83:5:992.15 and then stirred evenly to obtain a nucleating solution. Then place the substrate with loose and orderly arranged polystyrene sphere templates on it in a nucleation solution at 25°C for 100 seconds, and obtain silver seeds growing between the polystyrene spheres on the substrate. crystal ...

Embodiment 2

[0026] The concrete steps of preparation are:

[0027] In step 1, a solution of polystyrene spheres with a concentration of 2.4wt% and a diameter of 500 nm is coated on a substrate; wherein the substrate is a silicon wafer, and the coating is performed by spin coating. Then place the substrate with polystyrene balls on it in a plasma cleaning machine and use argon plasma etching for 7 minutes; wherein, the etching power is 18W, and the polystyrene balls with loose and orderly arrangements on it are obtained. Substrate for vinyl sphere templates.

[0028] In step 2, silver nitrate, hydrofluoric acid with a concentration of 39wt% and water are mixed according to the weight ratio of 0.84:5:993.15 and then stirred evenly to obtain a nucleating solution. Then place the substrate with loose and orderly arranged polystyrene sphere templates on it in a nucleation solution at 26°C for 95 seconds, and obtain silver seeds growing between the polystyrene spheres on the substrate. crysta...

Embodiment 3

[0032] The concrete steps of preparation are:

[0033] In step 1, a solution of polystyrene balls with a concentration of 2.5 wt % and a diameter of 1300 nm is coated on a substrate; wherein the substrate is a silicon wafer, and the coating is performed by spin coating. Then place the substrate with polystyrene balls on it in a plasma cleaning machine and use argon plasma etching for 23 minutes; wherein, the etching power is 18W, and the polystyrene balls with loose and orderly arrangements on it are obtained. Substrate for vinyl sphere templates.

[0034] In step 2, silver nitrate, hydrofluoric acid with a concentration of 40wt% and water are mixed according to the weight ratio of 0.85:5:994.15 and stirred evenly to obtain a nucleating solution. Then place the substrate with loose and orderly arranged polystyrene sphere templates on it in a nucleation solution at 27°C for 90 seconds, and obtain silver seeds growing between the polystyrene spheres on the substrate. crystal n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com