Magnetic nano-pore metal-organic framework core-shell material preparation, functionalized design, and application.

An organic framework and magnetic nanotechnology, applied in the field of synthesis of magnetic core-shell materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

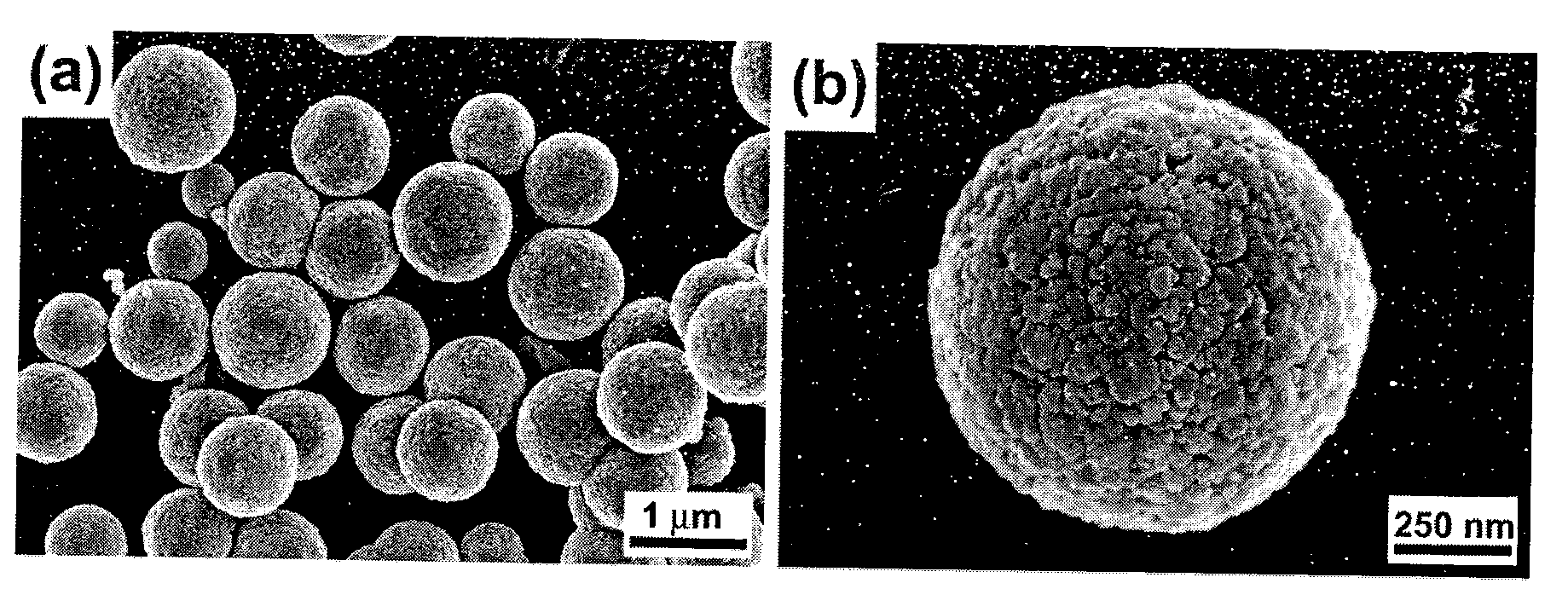

[0041] Magnetic Fe 3 o 4 The nanosphere core was synthesized with reference to the method provided by Zhao D.Y. et al. in Advanced Materials 2009, Volume 21, pages 1377-1382. Weigh 1.73g of ferric chloride hexahydrate, dissolve it in 35mL of ethylene glycol, and stir it magnetically. After it is completely dissolved, add 3.83g of sodium acetate trihydrate, continue stirring for 30 minutes, and then transfer the entire solution into an autoclave. After reacting at 200 degrees Celsius for 8 hours, cool to room temperature, and separate the precipitate by adding an external magnet. The prepared black product was washed with a large amount of distilled water, and then washed with absolute ethanol, and then dispersed in absolute ethanol for storage. The obtained product morphology is characterized by a scanning electron microscope, and its diameter is 400-700nm (see figure 1 ).

[0042] Weigh the Fe prepared above 3 o 4 Add 0.05g of nanospheres to 10mL of a prepared ethanol so...

Embodiment 2

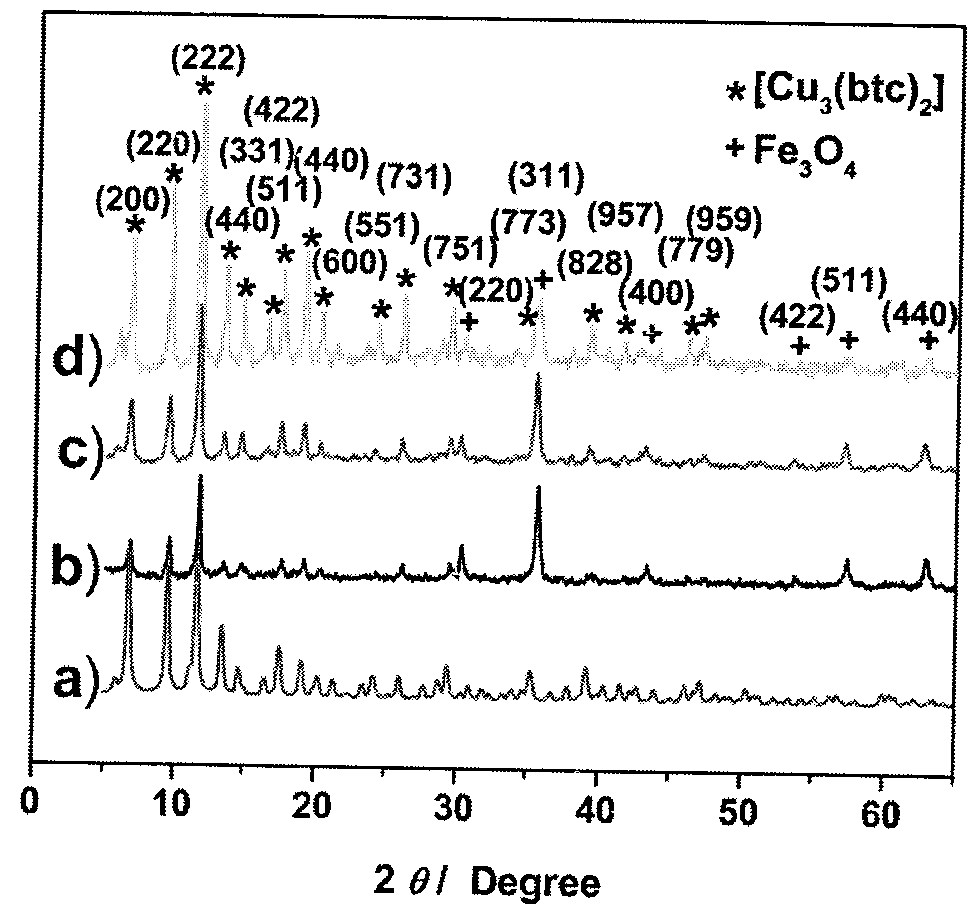

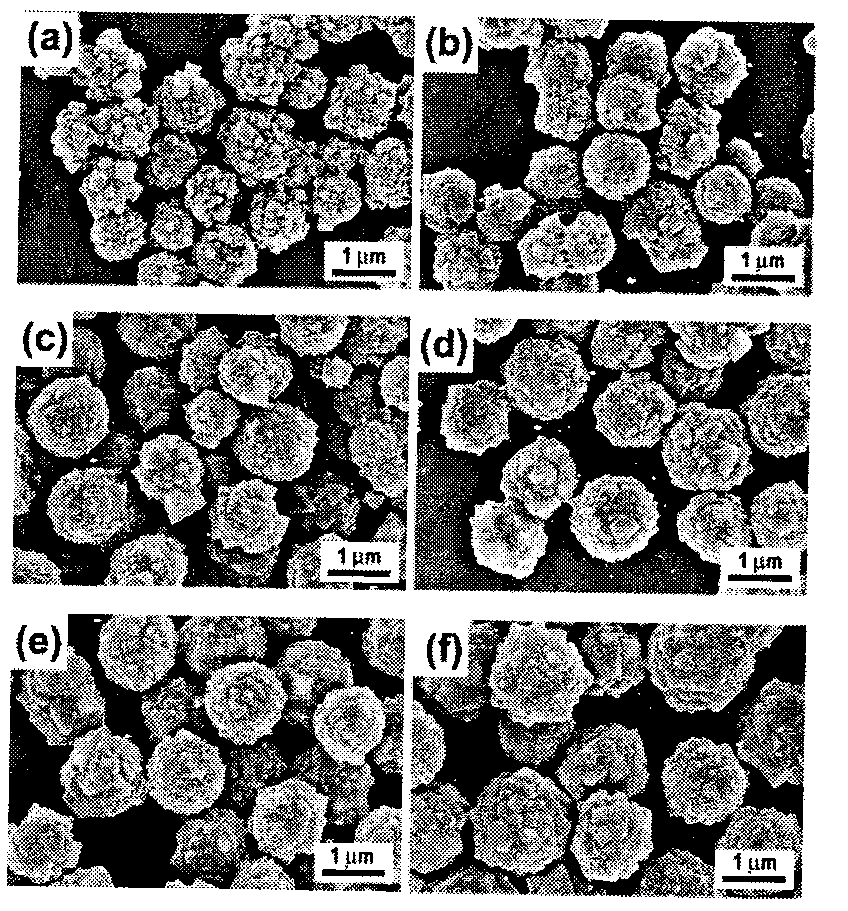

[0045] The Fe of the mercaptoacetic acid modification prepared in embodiment 1 3 o 4 Nanospheres are separated by a magnet, add 4mL prepared 10mmol / L copper acetate monohydrate ethanol solution, soak for 15 minutes at 70 degrees Celsius, separate with a magnet, wash with absolute ethanol, and then add 4mL prepared 10mmol / L Trimellitic acid ethanol solution, after 30 minutes, separated with a magnet, washed with absolute ethanol, and obtained a layer of Cu 3 (BTC) 2 Skeleton core-shell material, the above process is repeated to prepare magnetic core-shell microspheres with different coating layers, and then put the product into a drying oven at 150 degrees Celsius for 10 hours to dry. The prepared product is characterized by powder X-ray diffraction method, and the product contains Fe 3 o 4 and nanoporous metal-organic framework phase [Cu 3 (BTC) 2 (H 2 O) 3 ] n ; product morphology through scanning electron microscopy (see Figure 6 ) and transmission electron micros...

Embodiment 3

[0047] The Fe of the mercaptoacetic acid modification prepared in embodiment 1 3 o 4 The nanospheres are separated by a magnet, add 4mL of a prepared 10mmol / L ferric chloride hexahydrate ethanol solution, after 15 minutes, separate with a magnet, wash with absolute ethanol, and then add 4mL of a prepared 10mmol / L trimesic acid Ethanol solution, after 30 minutes, separated by magnet, washed with absolute ethanol, obtained a layer of MIL-100 (Fe) skeleton core-shell material, and the above process was repeated to prepare magnetic core-shell microspheres with different layers of coating. The temperature of the reaction was controlled at 25 degrees Celsius, and then the product was put into a drying oven and dried at 150 degrees Celsius for 10 hours. The prepared product is characterized by powder X-ray diffraction method, and its structure is except containing Fe3O4 phase, also contains the nanoporous metal-organic framework material MIL-100 (Fe) phase (see Figure 8 ); the mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com